Box dividing adhesive tape for architectural ornament and building wall face coating technology

A technology for architectural decoration and partitioning, which is used in construction, building construction, adhesives, etc., can solve the problems of wasting construction time, polluting the color of the primer, affecting the progress of the project, etc., and achieves diversified and simple external visual effects. The effect of firmness and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

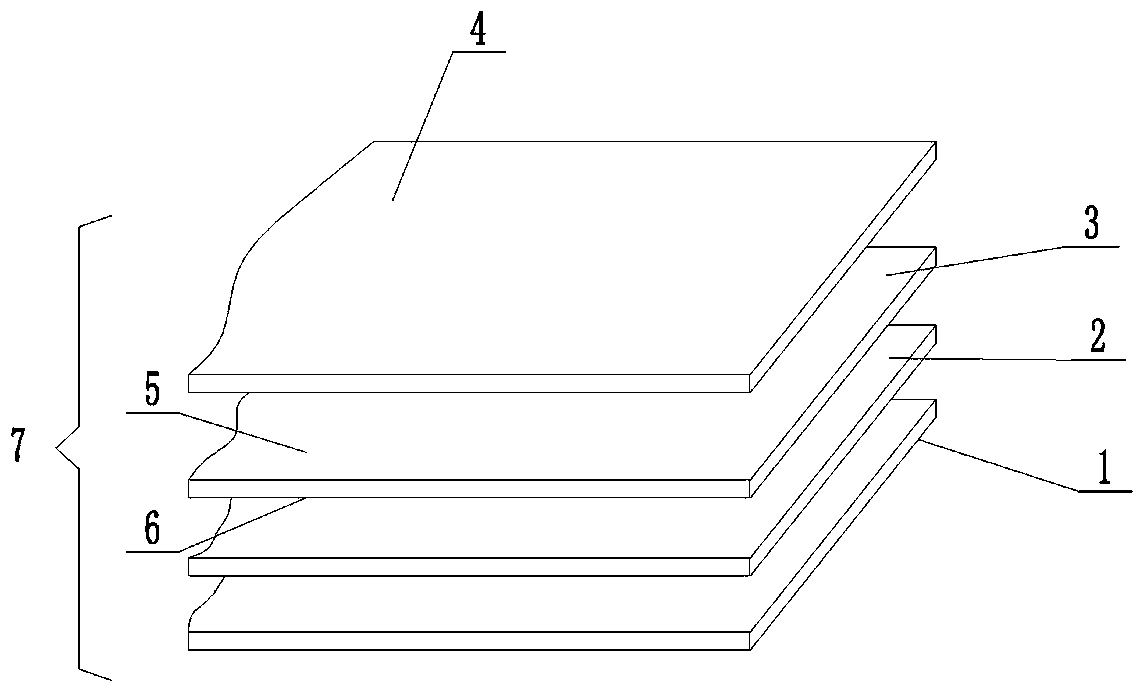

[0035] Embodiment 1: Grid tape 7 for building exterior walls.

[0036] The BOPP matting film with a thickness of 13 μm is bonded and compounded with the single-sided release paper 4, and the film surface bonded with the single-sided release paper 4 is the high corona surface 5, and the corona value is 42 dynes. The release surface of the single-sided release paper 4 and the low corona surface 6 with a corona value of 36 dynes are outside the complex; On the corona matting surface, the thickness of the paint film is 50 μm, and after drying, it is sprayed with water-based acrylic elastic waterproof emulsion with a glass transition temperature of -5 °C. After the surface is dry, it can be rolled up and cut into tapes with a width of 0.5 to 3.0 cm, and packed and sealed into boxes.

[0037] When constructing on the building site, first apply a water-based acrylic elastic waterproof emulsion with a glass transition temperature of -5°C on the grid line, and then stick the grid tape...

Embodiment 2

[0040] Embodiment 2: Adhesive tape for building interior walls.

[0041] The process is the same as that described in Example 1, except that the BOPP film is a high-gloss film, and the low-corona surface 6 is a high-gloss surface; the water-based paint used is a water-based metallic paint; after the paper-plastic composite is removed, a high-gloss metallic effect is formed , can be used as decorative lines.

Embodiment 3

[0042] Example 3 Patterned Building Decorating Tape.

[0043] The process is the same as that described in Example 1; the difference is that the water-based paint used is a combination of multiple and multi-colored water-based paints.

[0044]The high corona surface 5 of the BOPP matting film with a thickness of 18 μm is bonded to the single-sided release paper 4, and the corona value of the high corona surface 5 is 40 dynes; the corona value of the low corona surface 6 is 35 dynes ; The transparent water-based varnish is sprayed on the low corona surface 6 of the matting film, and the paint film thickness is 20 μm. After it dries, use a screen printing plate to print the toning metallic paint on the paint film to form a pattern; Color water-based paint; spray water-based pressure-sensitive adhesive after drying. It can be rolled up for slitting, packaging, sealing and packing when it is surface dry.

[0045] When constructing the wall, first paste it to the wall and then ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corona value | aaaaa | aaaaa |

| corona value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com