Integrated oxygen supply valve

An integrated oxygen supply technology, which is applied in the direction of valve devices, fluid treatment, fluid treatment accessories, etc., can solve the problems of lack of decompression, pressure stabilization function, self-sealing filling function, poor sensitivity of gas outlet, and restrictions on popularization and application. It achieves the effects of simple and convenient filling operation and use, reduced space occupation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

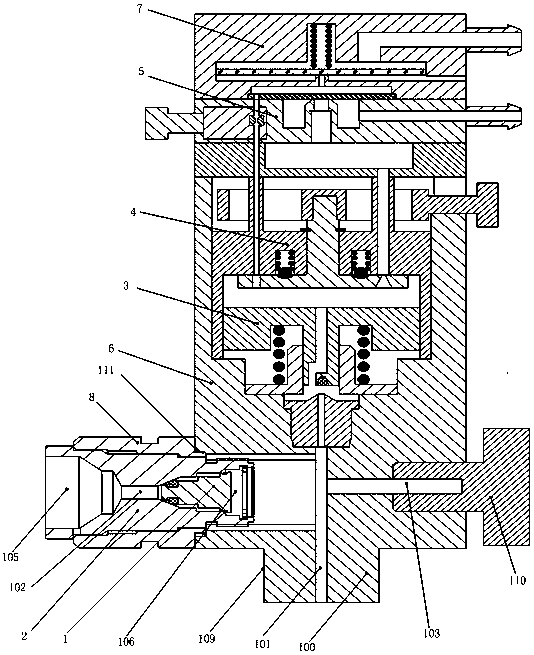

[0043] Such as figure 1 As shown, an integrated oxygen supply valve of the present invention includes a valve body 6, a valve cover 7, a filling module 8 installed on the valve body 6 and the valve cover 7, a pressure reducing and stabilizing module 3, a flow regulating Module 4 and pulse oxygen supply module 5; the oxygen in the gas tank 108 is output by the pulse oxygen supply module 5 after passing through the filling module 8, the decompression and stabilization module 3, and the flow regulation module 4. The following are introduced respectively:

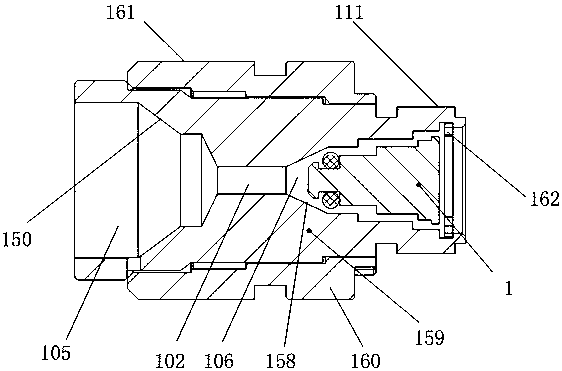

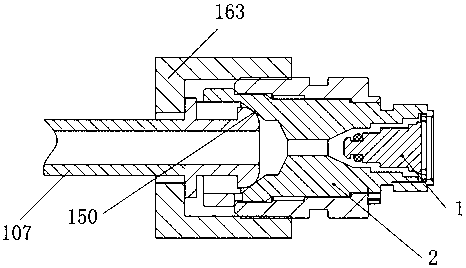

[0044] 1. Filling module

[0045] The filling module 8 includes a valve body 6 and an inflation joint 2 installed at the inlet end 100 of the valve body. The inlet end 100 is provided with a first air passage 101 passing through the inlet end 100 of the valve body. The outlet of the first air passage 101 is The outer ring is provided with a tank interface 109; the tank interface 109 is matched with the interface of the gas ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com