Online sizing material sampling device

A sampling device and rubber material technology, applied in the sampling device and other directions, can solve the problems of reduced error correction efficiency, reduced reference effect of submitted samples for verification, and high labor participation, so as to improve the stability of rubber materials, improve the rubber mixing process, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

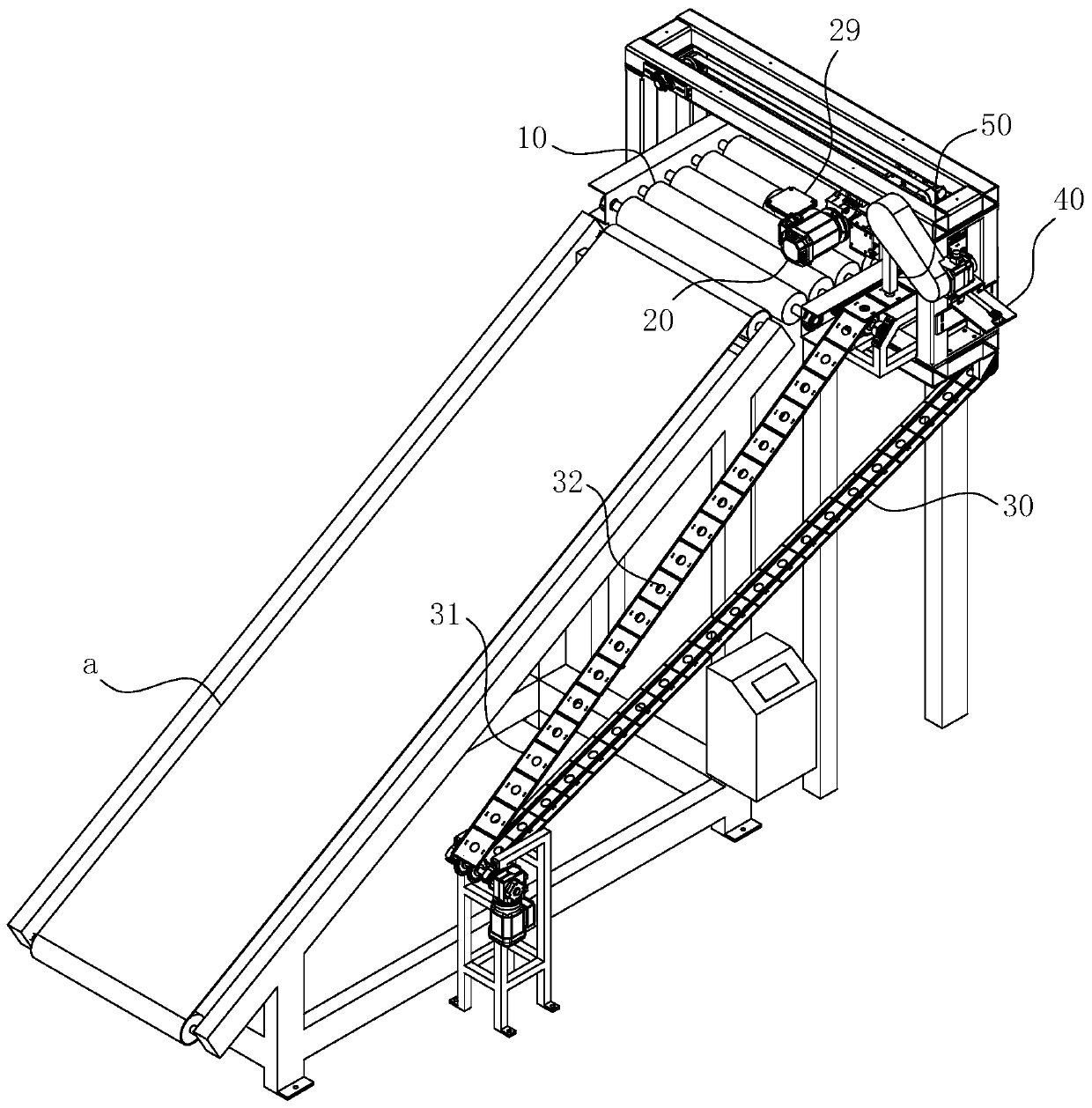

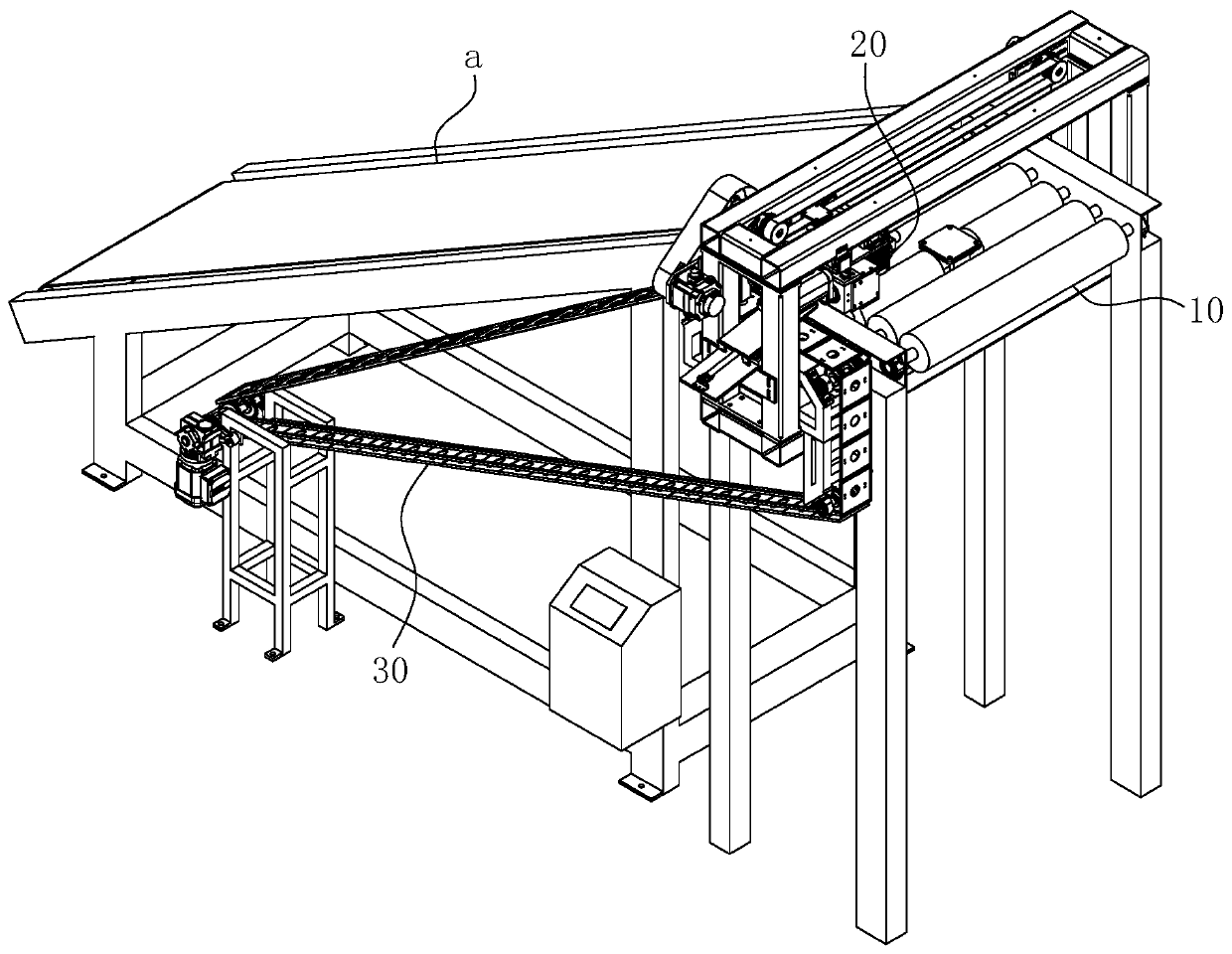

[0054] For ease of understanding, combined here Figure 1-12 , the concrete structure and working mode of the present invention are further described as follows:

[0055] The specific embodiment of the present invention is as Figure 1-2 As shown, it is arranged on one of the conveying sections of the feeding conveying belt a. The advantage is that the various structures of the present invention are directly installed by using the on-site conveying tape and even the conveying roller as a prototype, and the replacement cost is low; and the present invention is independently controlled, which obviously does not affect the original conveying control chain, and serves multiple purposes.

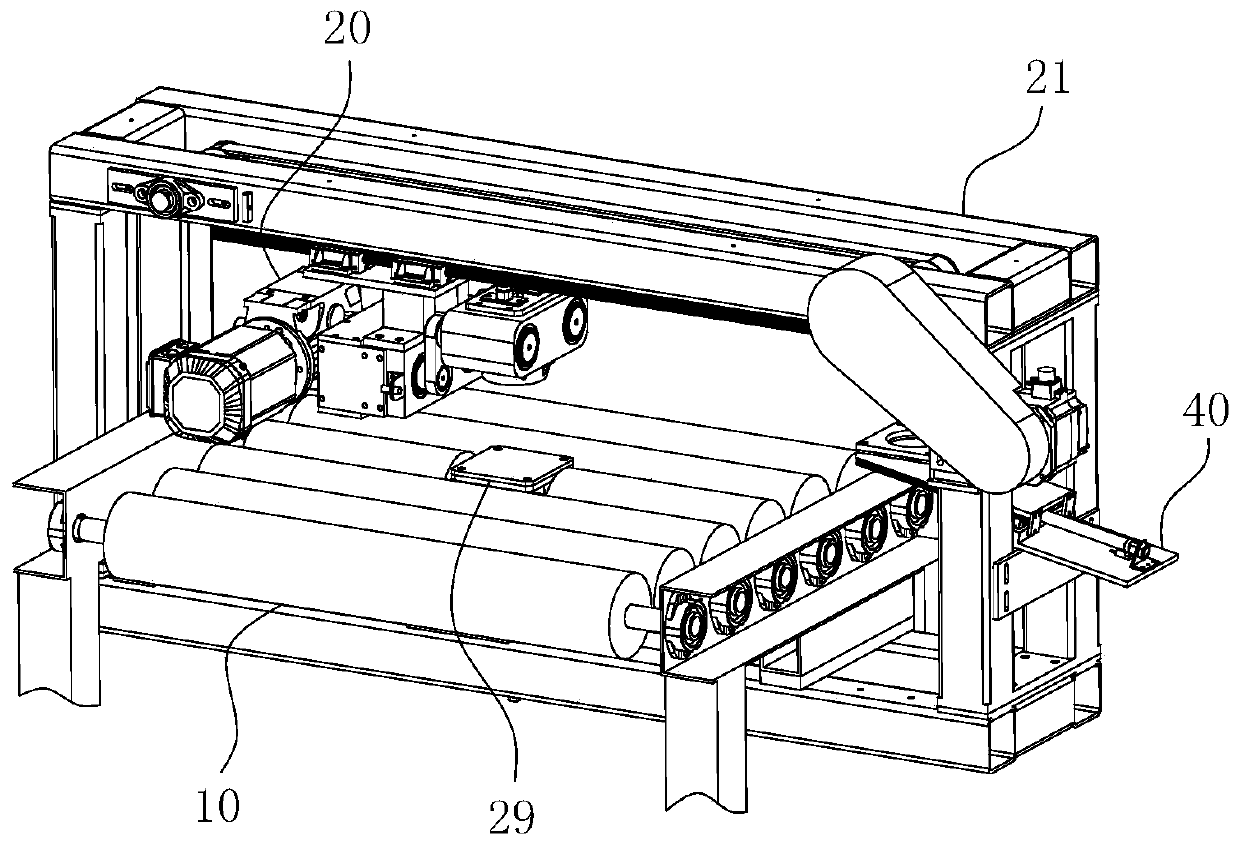

[0056] During actual assembly, the present invention mainly includes five major parts: the conveying assembly 10 , the glue cutting assembly 20 , the material receiving assembly 30 , the heating assembly 40 and the coding assembly 50 . in:

[0057] (1) Conveyor assembly 10

[0058] Conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com