VCSEL device with transparent top lining, back positive electrode and back negative electrode, and preparation method thereof

A positive and negative electrode, backside technology, applied in the field of VCSEL devices and their preparation, can solve the problems of increasing inductance, the effect of light extraction efficiency, and the need for wire bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

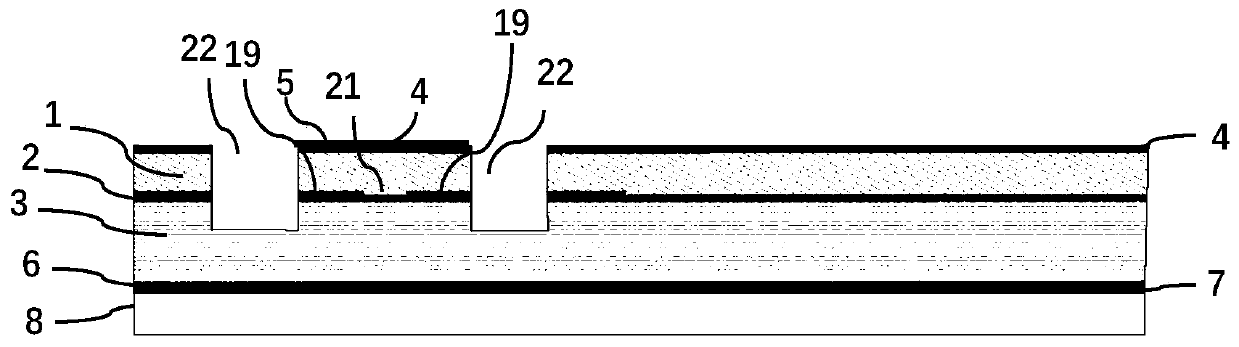

[0073] This embodiment provides a VCSEL device with a sapphire transparent top lining and a positive and negative electrode on the back side and a preparation method thereof, such as figure 1 As shown, on the front of the epitaxial layer, the yellow light process, the evaporation of the P-type ohmic metal layer 5, the deposition of the first passivation layer 4, and the etching process are sequentially performed, the quantum well layer 2 is etched through, and part of the N-type DBR layer 3 is etched to form a trench. The groove 22, the VCSEL unit mesa structure and the corresponding light-emitting area are then oxidized to form an oxide layer 19, and the material of the P-type ohmic metal layer is Ti.

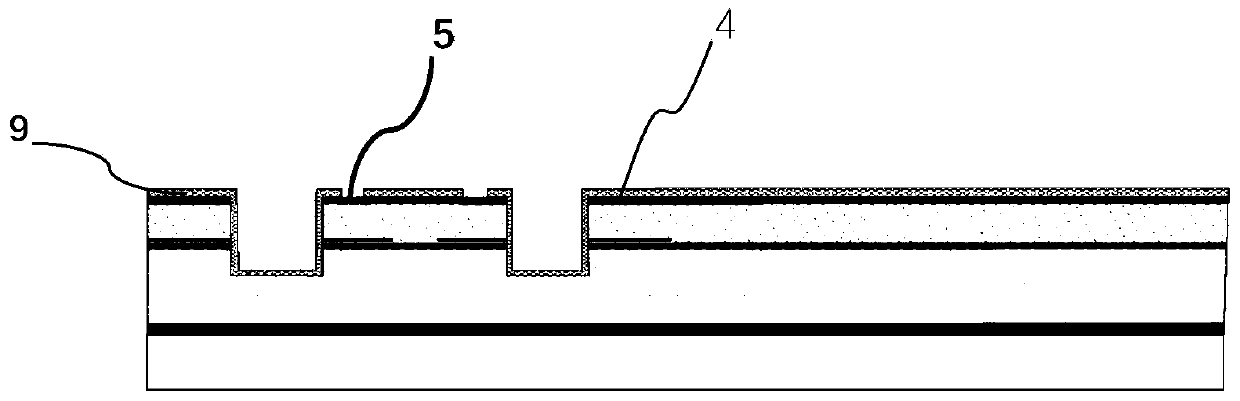

[0074] Such as figure 2 As shown, the second passivation layer 9 is deposited on the first passivation layer 4 , and the second passivation layer 9 is etched to expose the P-type ohmic metal layer 5 .

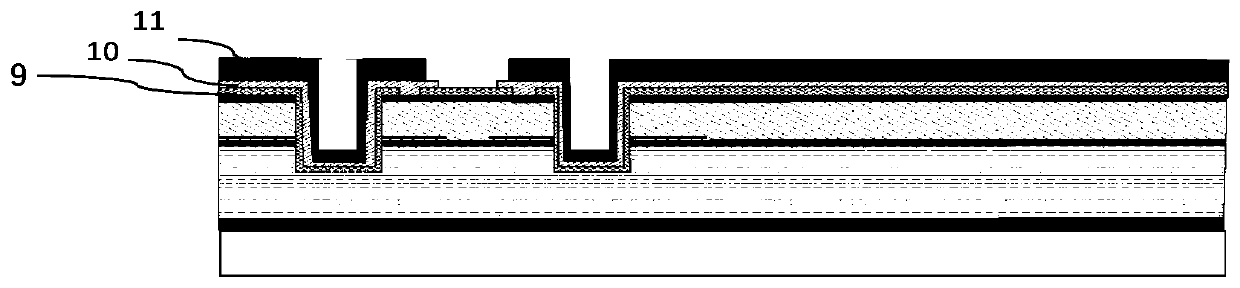

[0075] Such as image 3 As shown, a front seed metal layer 10 and an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com