Comprehensive method for pig farm odor emission reduction

A comprehensive method and pig farm technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as pig farm odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

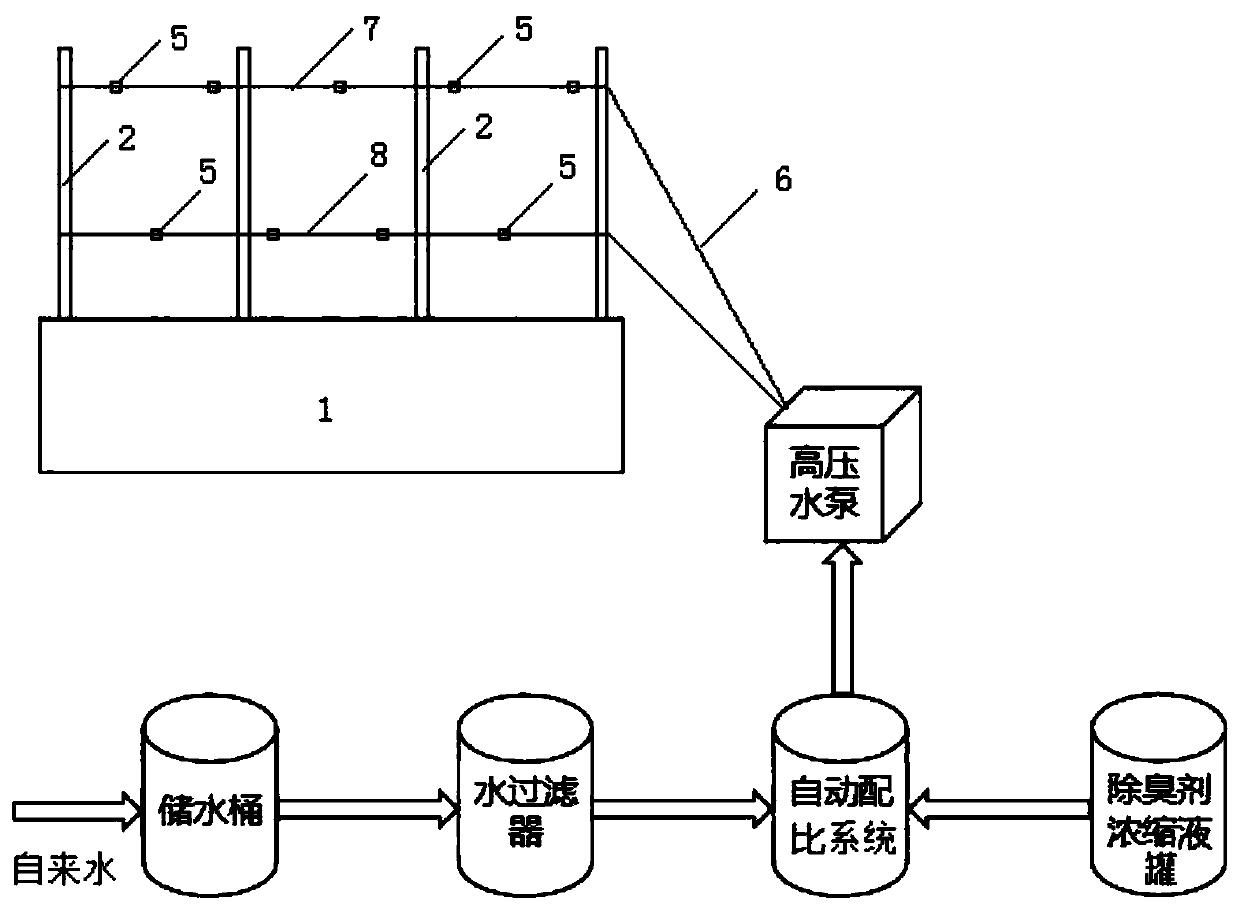

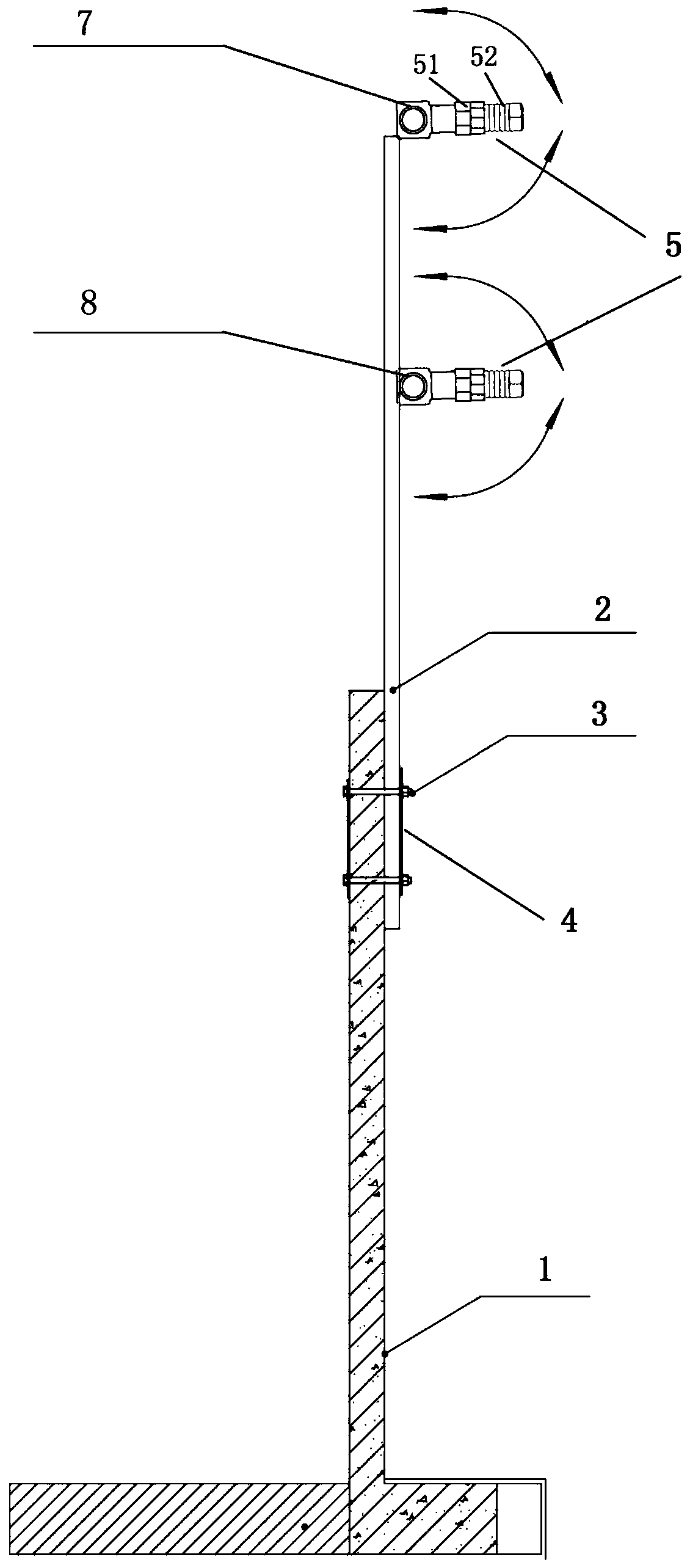

[0028] The present invention is a comprehensive method for reducing the emission of odor from traditional open or semi-open pig farms, which includes: reducing the emission of odor by using the method of front-end control + process control + terminal control;

[0029] (1) Front-end control method: add fermented feed, yucca extract and coated lactic acid bacteria to commercial pig feed; in commercial pig feed, the addition ratio of fermented feed is 5%-10%, 8% is better; yucca The addition ratio of the extract is 0.01%-0.03%, 0.02% is better; the addition ratio of coated lactic acid bacteria (coated Enterococcus faecium) is 0.03%-0.05%, and 0.04% is better; that is, every ton of commercial pig feed Among them, the addition ratio of fermented feed is 50-100kg, 80kg is better; the addition amount of yucca extract is 100g-300g, 200g is better; in each ton of feed, the addition amount of coated lactic acid bacteria (coated Enterococcus faecium) 300g-500g, preferably 400g.

[0030]...

Embodiment 2

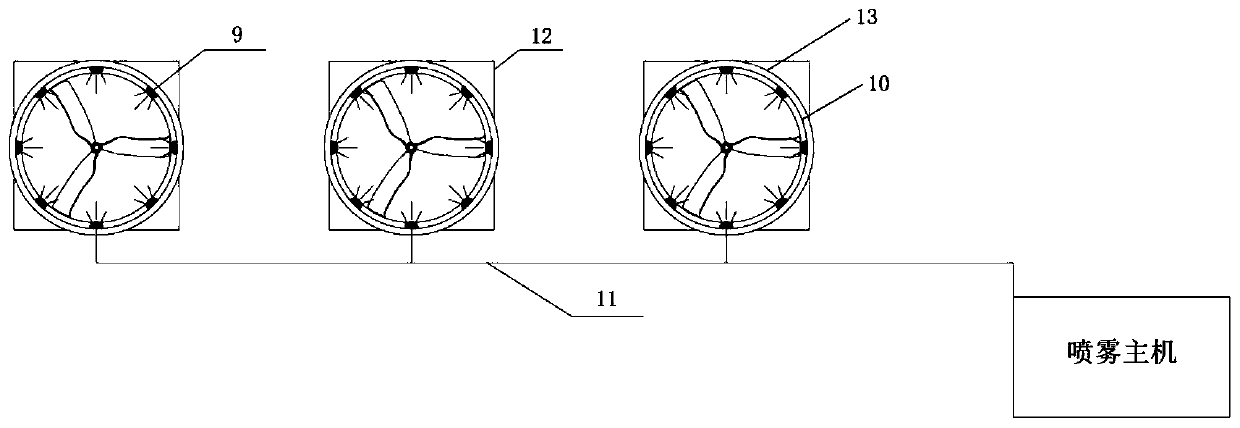

[0045] A comprehensive method for reducing odor emissions in closed pig farms, including: using front-end control + process control + terminal control methods to reduce odor emissions;

[0046] (1) Front-end control method: add fermented feed, yucca extract and coated lactic acid bacteria to commercial pig feed; in commercial pig feed, the addition ratio of fermented feed is 5%-10%, 8% is better; yucca The addition ratio of the extract is 0.01%-0.03%, 0.02% is better; the addition ratio of coated lactic acid bacteria (coated Enterococcus faecium) is 0.03%-0.05%, and 0.04% is better; that is, every ton of commercial pig feed Among them, the addition ratio of fermented feed is 50-100kg, 80kg is better; the addition amount of yucca extract is 100g-300g, 200g is better; in each ton of feed, the addition amount of coated lactic acid bacteria (coated Enterococcus faecium) 300g-500g, preferably 400g.

[0047] The fermented feed is a product made of corn, soybean meal and bran mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com