Preparation method of high-stability platinum complex catalyst and application thereof

A platinum complex and high-stability technology, which is applied in the preparation of hydrosilylation silicone resin and hydrosilylation silicone rubber, can solve problems such as gelation, crosslinking failure, and inhibitor volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

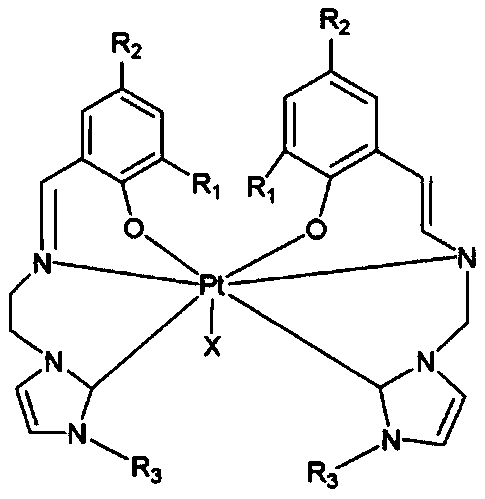

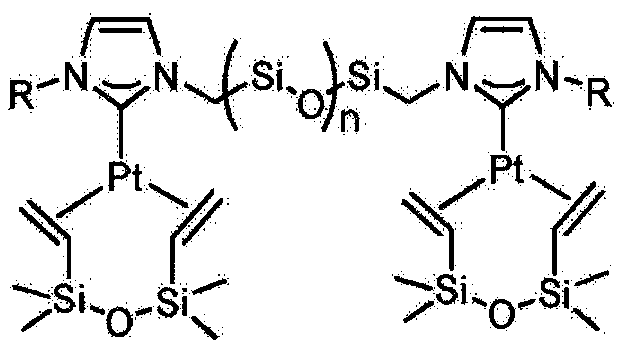

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 (comparative example)

[0071] Preparation of Ordinary Karstedt Catalyst

[0072] This embodiment 1 is a comparative example for implementing 2 and 3, and is also the basic process of subsequent related embodiments.

[0073] S1. Weigh 1000g of isopropanol and 4500g of divinyltetramethyldisiloxane into a 10L glass reactor, stir to dissolve and disperse evenly;

[0074] S2, feed nitrogen into the container, add a mixed solution of 300g hexachloroplatinic acid hexahydrate and 2000g isopropanol while stirring, and stir evenly;

[0075] S3, add 1200g sodium bicarbonate while stirring, stir evenly;

[0076] S4. Heating the temperature of the water bath in the jacket of the reaction kettle to 75-85°C, keeping the temperature of the reaction solution at 70-75°C, and stirring and reacting under the protection of nitrogen;

[0077] S5. Keep heating and stirring for 1-2 hours, until the reaction solution no longer deflates and bubbles, and the color turns milky whi...

Embodiment 2

[0083] Preparation of highly stable platinum complex catalyst A

[0084] S1. Weigh 1000g of isopropanol and 4500g of divinyltetramethyldisiloxane into a 10L glass reactor, stir to dissolve and disperse evenly;

[0085] S2, feed nitrogen into the container, add a mixed solution of 300g hexachloroplatinic acid hexahydrate and 2000g isopropanol while stirring, and stir evenly;

[0086] S3, add 1200g sodium bicarbonate while stirring, stir evenly;

[0087] S4. Heating the temperature of the water bath in the jacket of the reaction kettle to 75-85°C, keeping the temperature of the reaction solution at 70-75°C, and stirring and reacting under the protection of nitrogen;

[0088] S5. Keep heating and stirring for 1 to 2 hours until the reaction solution no longer deflates and bubbles, and the color becomes milky white, then add 600g of nitrogen-containing compound as a modification additive, and continue to maintain the temperature of the jacketed water bath of the heating reactor t...

Embodiment 3

[0094] Preparation of highly stable platinum complex catalyst B

[0095] The steps of the operation method are the same as those in Example 2, except that the modification aid in step S5 is replaced with 600 g of phosphorus-containing compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com