Electron beam welding machine

A technology of electron beam and welding machine, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient utilization of vacuum chambers, and achieve the effect of improving the processing range of workpieces, reasonable structure, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

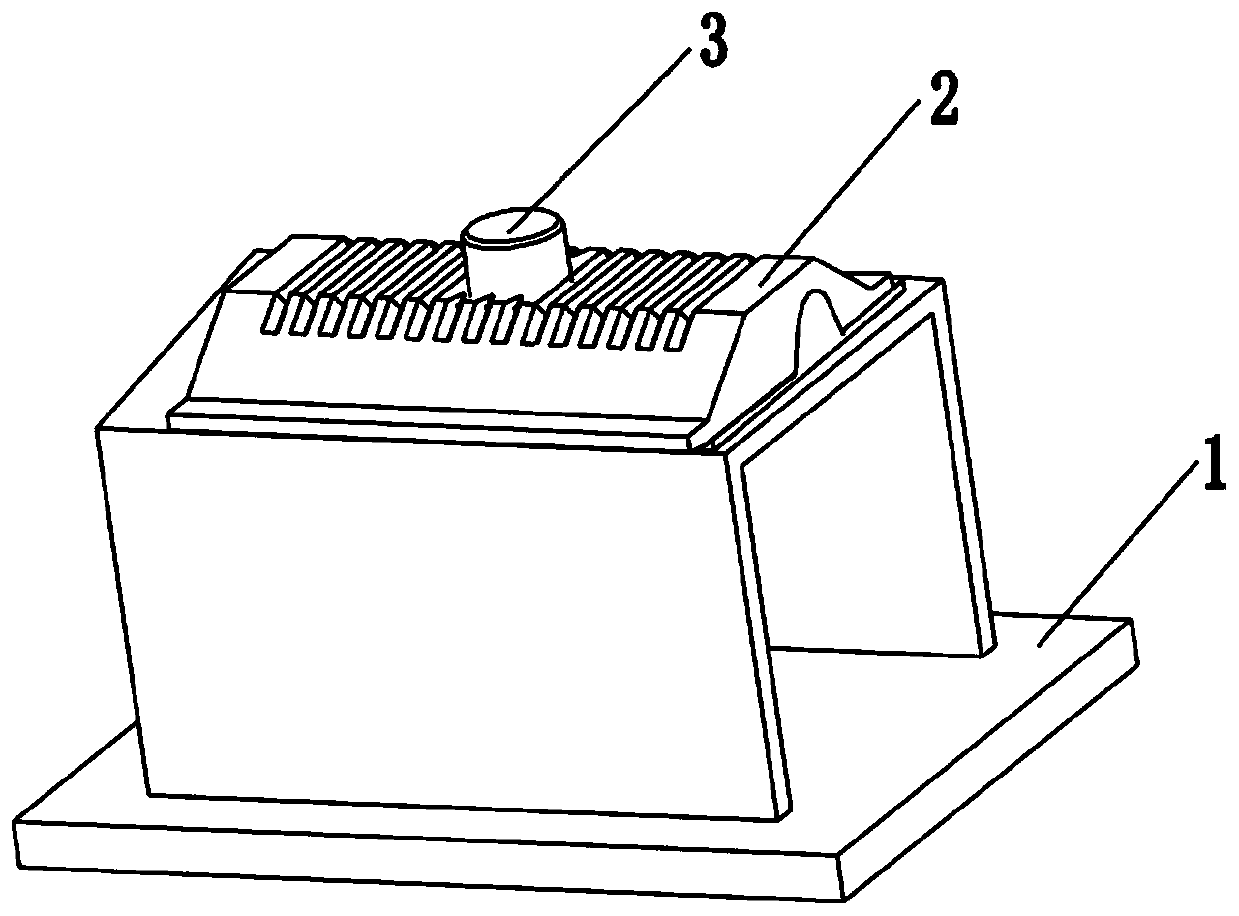

[0040] Depend on figure 1 As shown, the present invention provides an electron beam welding machine, which includes a frame mechanism 1 , a sealing mechanism 2 , a welding torch mechanism 3 and a driving mechanism 4 .

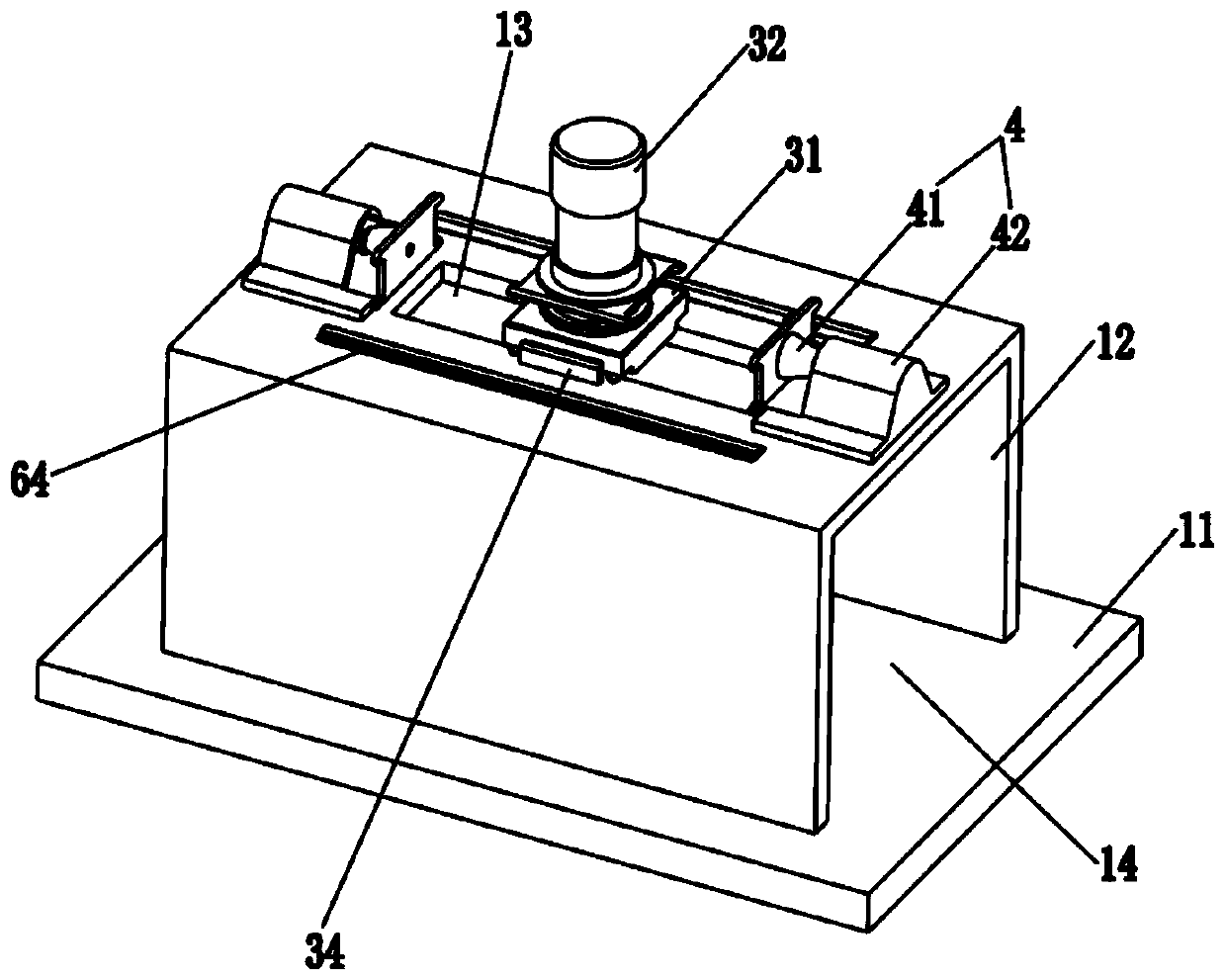

[0041]The frame mechanism 1 includes a frame built with a welding cavity 14 for vacuuming, and the frame is provided with a first opening 13 communicating with the welding cavity 14 . Such as figure 2 As shown, the base includes a base base 11 and a base body 12 arranged on the top of the base base 11. The base body 12 has a welding cavity 14 for vacuuming inside the base body 12. The top surface of the base body 12 A first opening 13 communicating with the welding cavity 14 is opened.

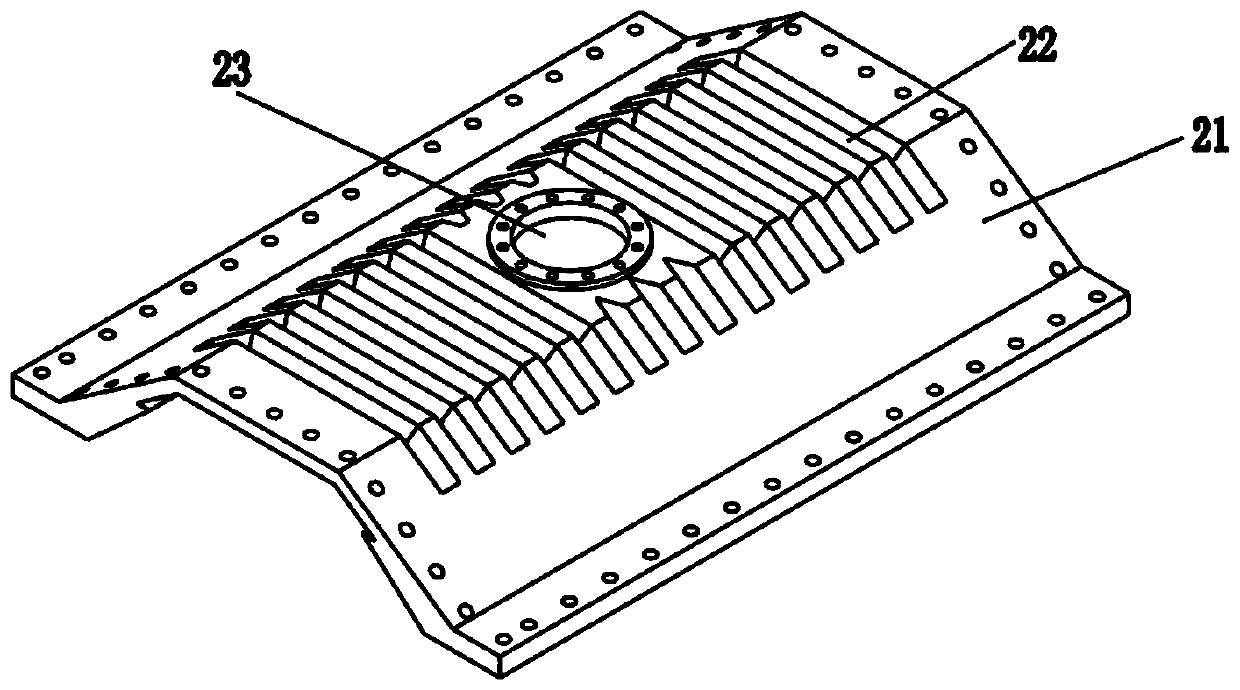

[0042] The sealing mechanism 2 includes a sealant seat 21 arranged on the machine base mechanism 1 and covering and sealing the first openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com