Cabin door heat sealing material component and preparation method thereof

A heat-sealing and cabin door technology, used in aircraft doors, aircraft accessories, textiles and papermaking, etc., can solve problems such as over-temperature in functional cabins, aircraft flight failures, and failure of cabin door heat-sealing functions, and achieve sealing and heat-resistance performance. Reliability, convenient installation, disassembly, replacement and maintenance, and strong structural adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

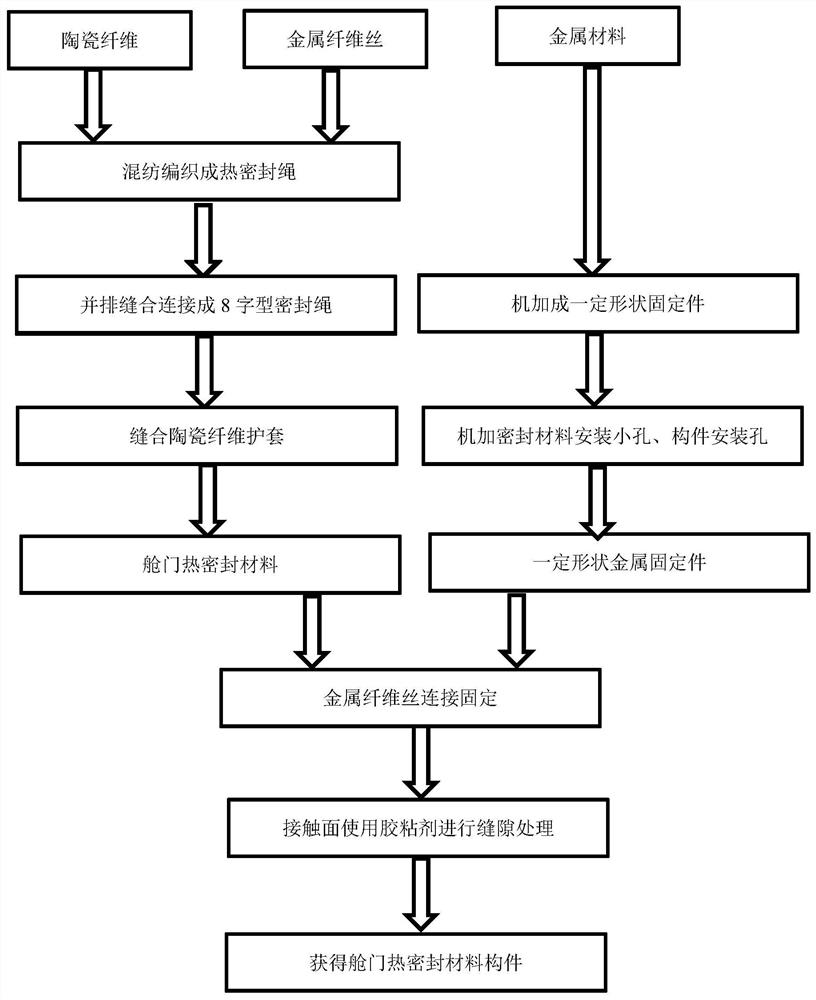

[0027] This embodiment provides a hatch door heat-sealing material component and its preparation method, according to image 3 Shown method flow process is prepared, specifically comprises the following steps:

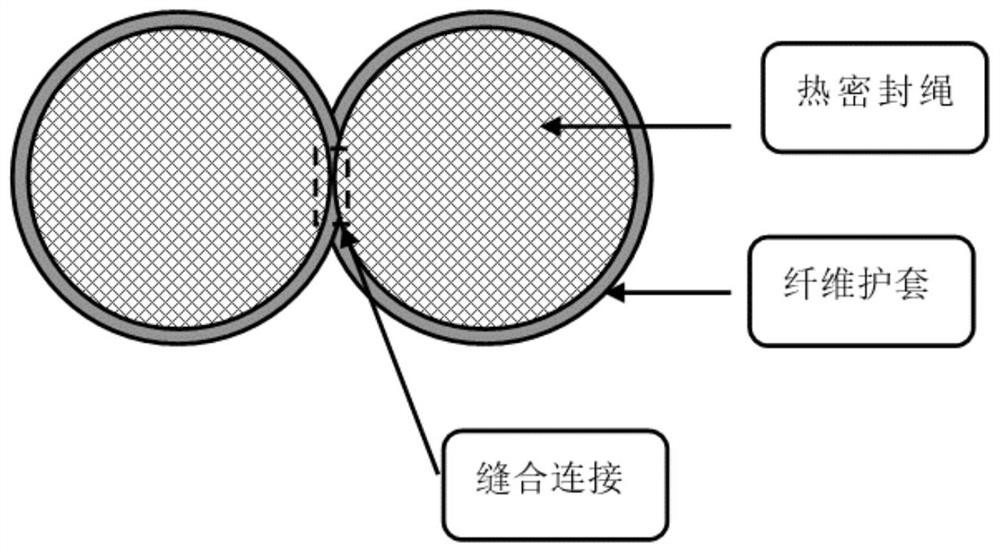

[0028] 200tex fiberglass with The stainless steel fiber wire is blended and woven according to the ratio of the number of strands at 5:1. heat-sealed rope. Cut two sections of the same length of the heat-sealed rope, use 1 strand of the same metal fiber wire to carry out 8-shaped side-by-side suture connection, and the suture stitch distance is 10mm to make a 8-shaped heat-sealed rope. Using this as a weaving template, weaving it into a ceramic fiber sheath online to make a heat-sealed material, such as figure 1 shown.

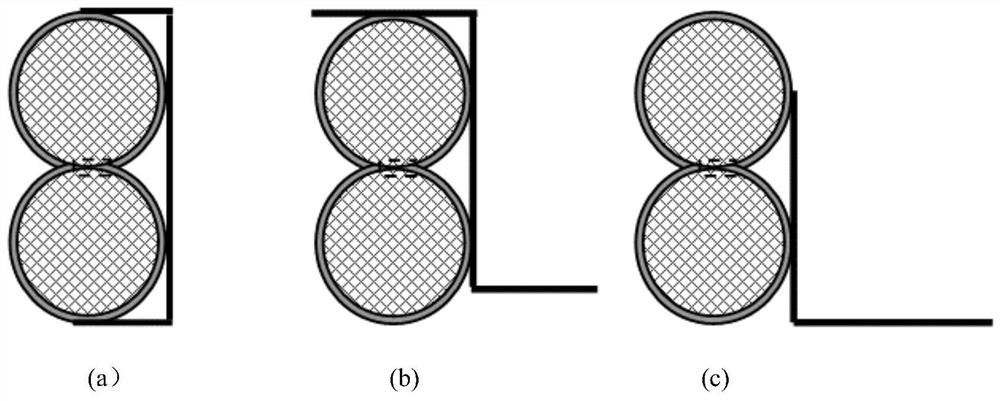

[0029] Use metal materials to process L-shaped metal fixing parts, and the installation hole diameter of the metal fixing parts is The hole distance is 30mm. The shape of the metal fixing piece is L-type or C-type or S-type, such as figure 2...

Embodiment 2~7

[0033] Table 1 shows the specific parameters of the preparation method of the hatch heat-sealing material components in Examples 2-7. Table 1 lists the specific parameters of Comparative Examples 1-3 at the same time.

[0034] Table 2 lists the performance data of the hatch heat-sealing material components prepared in Examples 1-7 and Comparative Examples 1-3. The hatch door heat-sealing component of the invention has the characteristics of high temperature resistance, low thermal expansion, low heat conduction, low leakage rate, good assembly, etc., and is an excellent hatch door heat-sealing material component.

[0035] Table 1

[0036]

[0037] Table 2

[0038]

[0039] About the way that the present invention is installed with the cabin door or the cabin door frame:

[0040] 1) figure 2 The installation method of the C-shaped structure and the door or door frame: the bottom of the C-shaped structure can rely on several threaded holes in itself, and rely on screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com