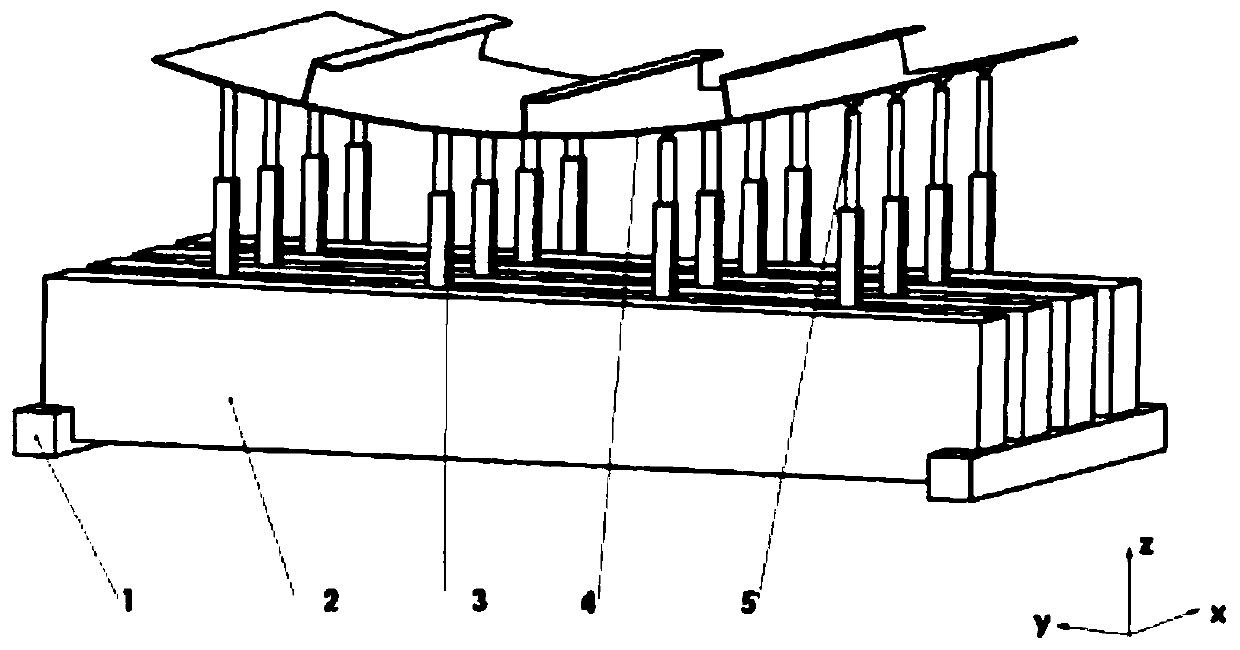

Supporting positioning device and method for laser welding of ribbed wall board

A technology of laser welding and support positioning, applied in laser welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of space structure interference, low utilization rate, large storage space, etc., to improve assembly efficiency and automation, control The effects of welding deformation and good heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

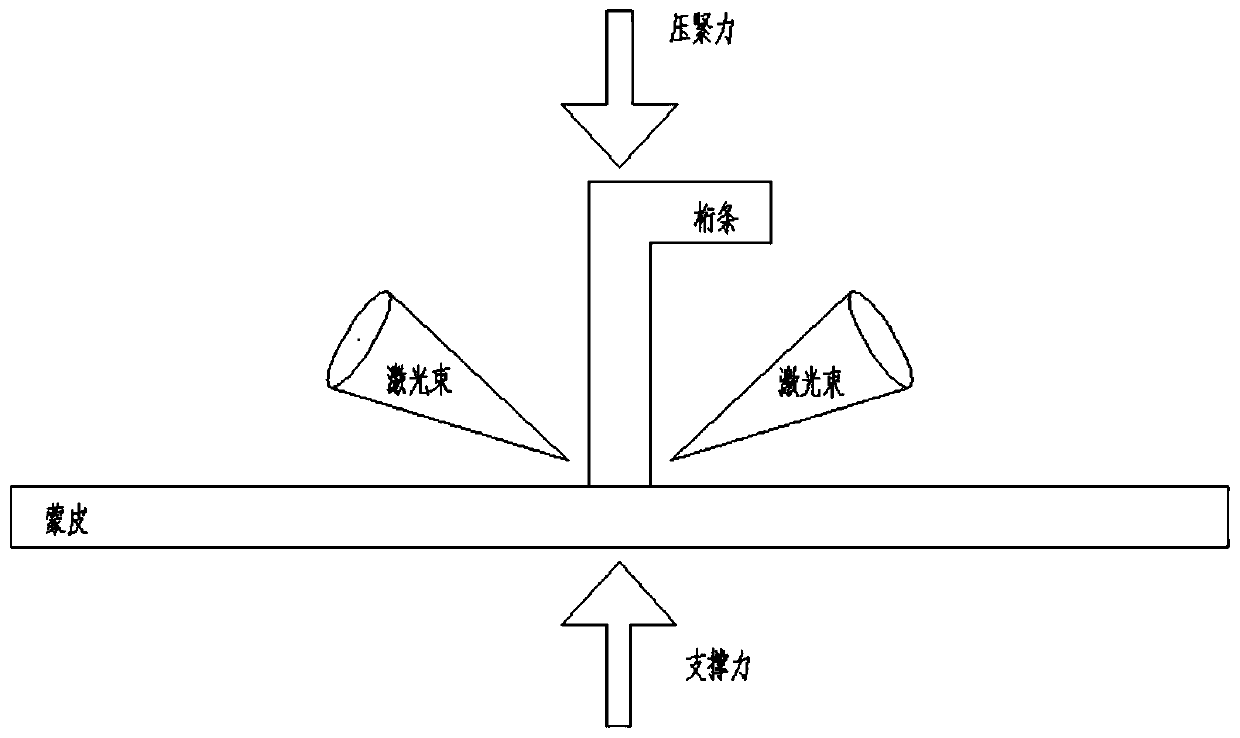

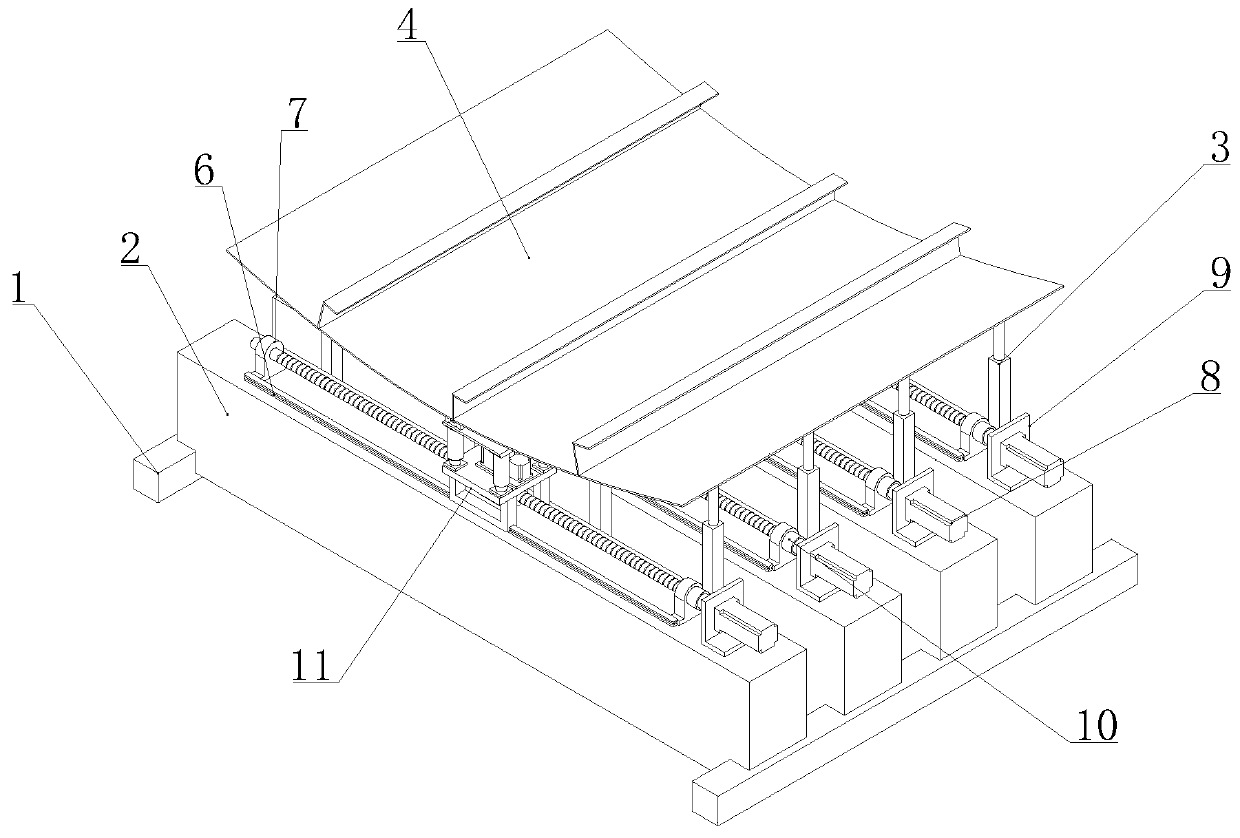

Method used

Image

Examples

specific Embodiment 1

[0062] Specific embodiment 1: take the supporting mechanism as an example from the lowest position to be welded, that is, the initial support position to the position to be welded adjacent to the initial support position, the spatial coordinates of the support position are (X 2 ,Z 3 ), then the space coordinate of the translation position is (X 1 ,Z 1 ), the space coordinate of the rotated position is (X 2 ,Z 2 ), then the translational distance of the support mechanism X 1 =X 2 +Z 1 sina, support mechanism lifting height Z 3 -Z 2 = Z 3 -Z 1 cosa, since the slope tana of the tangent line on the back of the ribbed panel 4 is known, the value of angle a is obtained according to arctana. According to common knowledge in the field, the value of angle a is less than 360°, so the value of angle a obtained according to arctana is unique . When the value of angle a is obtained, the values of sina and cosa are obtained immediately, so as to obtain the translation distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com