Gas pipeline weld joint protection device

A protection device and gas pipeline technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of not allowing repairs, waste of manpower and material resources, saving manpower and material resources, increasing compressive strength, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

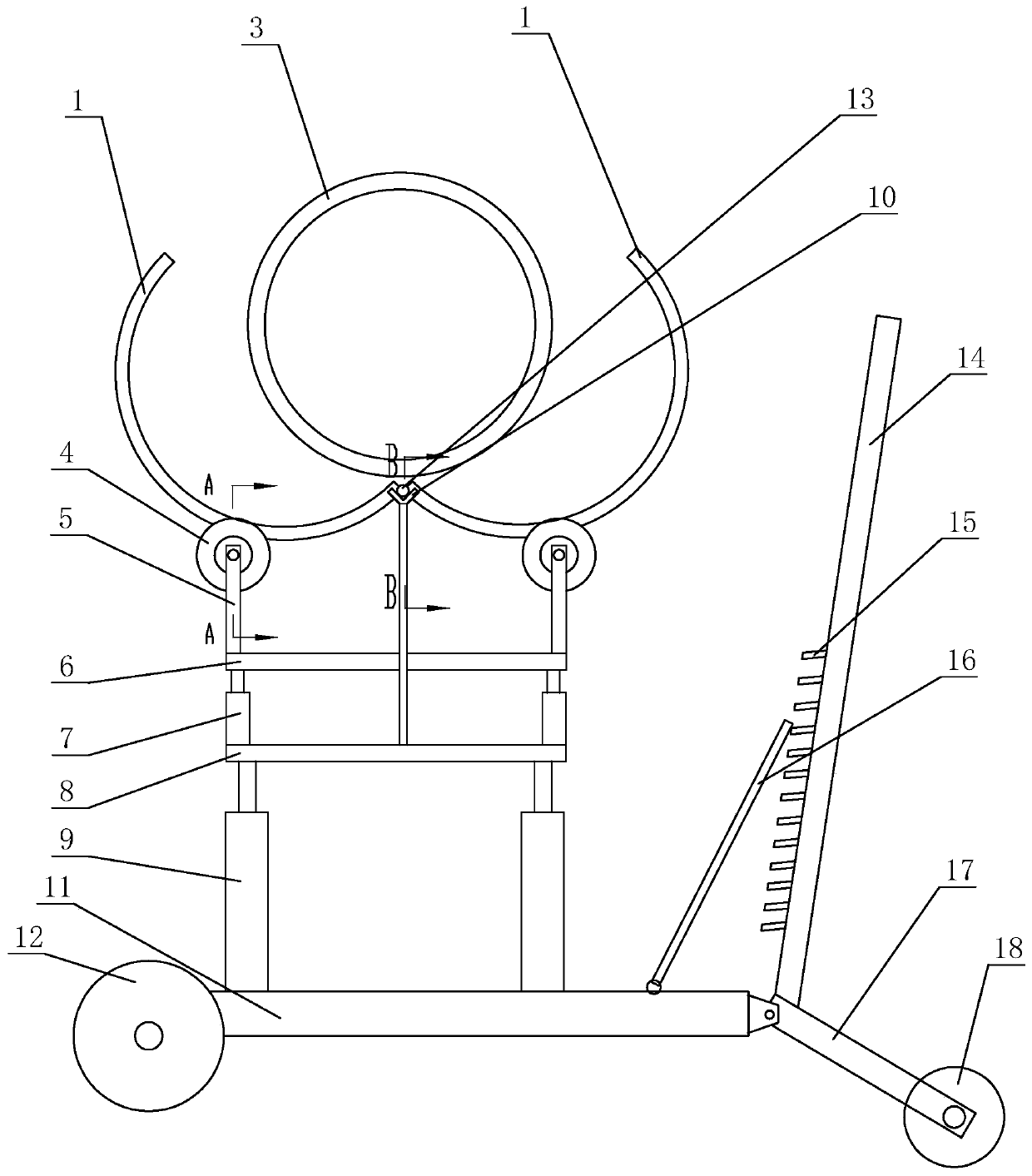

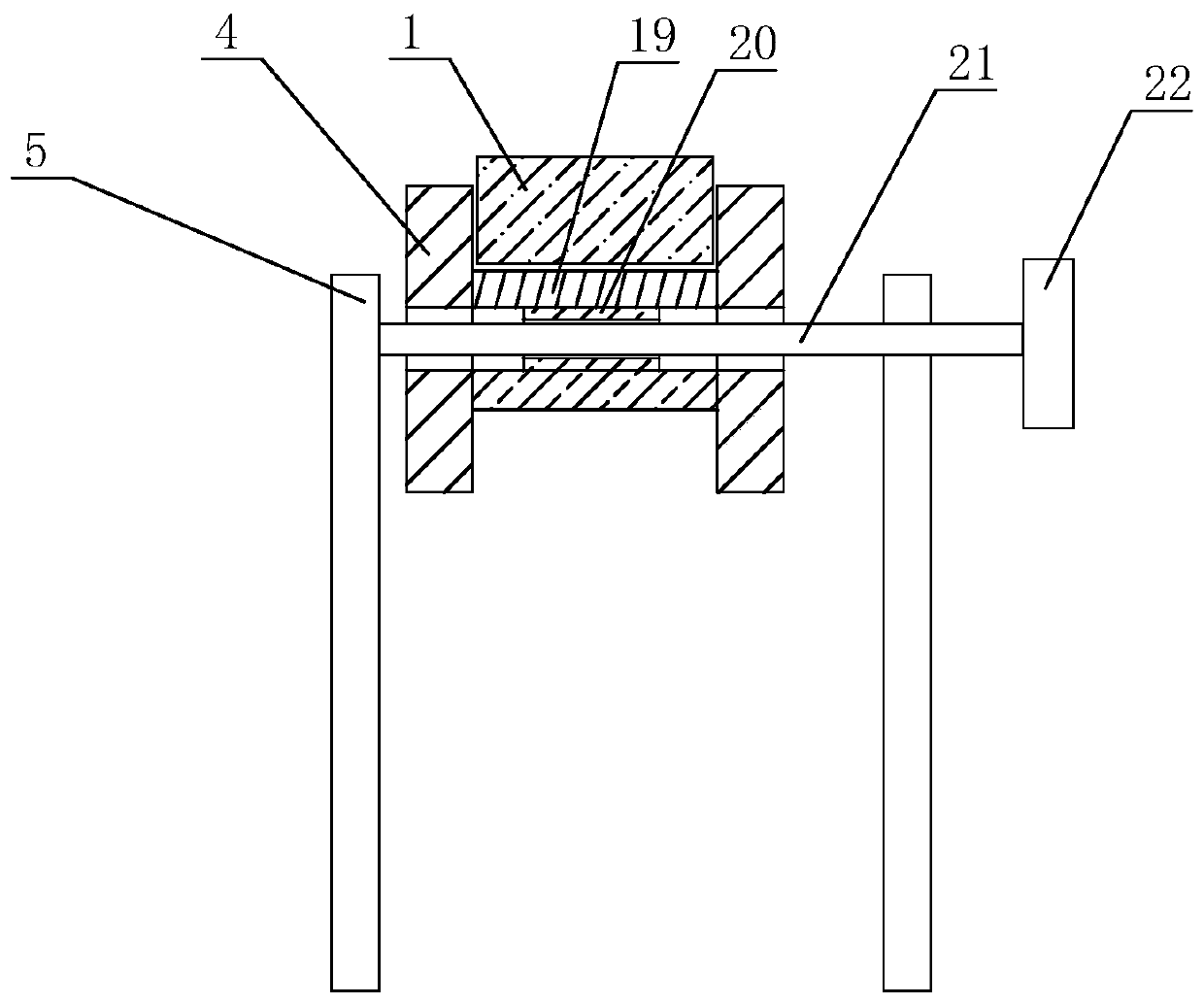

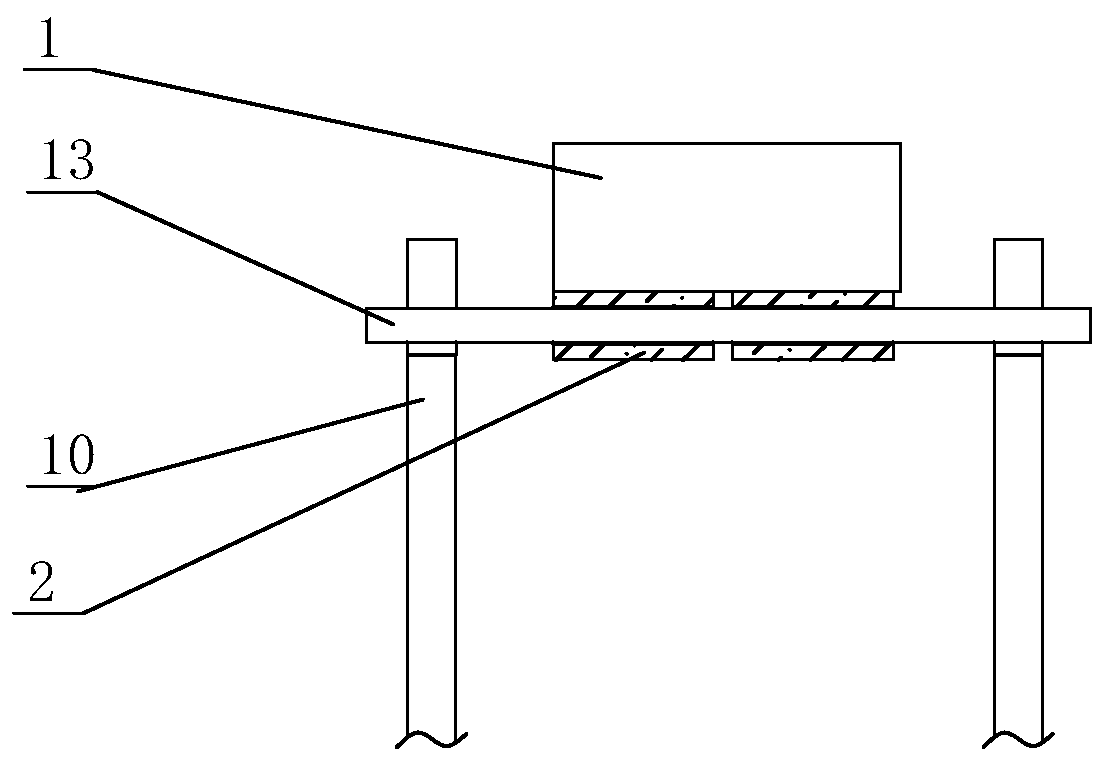

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0020] like Figure 1-Figure 3 as shown,

[0021] The gas pipeline weld protection device of the present invention comprises a chassis 11, two front wheels 12 are respectively installed on both sides of the front end of the chassis 11, two rear wheels 18 are respectively installed on the rear end of the chassis 11, and two main wheels 18 are vertically fixed on the upper surface of the chassis 11. Hydraulic cylinder 9, the piston rods of the two main hydraulic cylinders 9 are fixed on the same lifting plate 8, and the two auxiliary hydraulic cylinders 7 are vertically fixed on both sides of the lifting plate 8, and the piston rods of the two auxiliary hydraulic cylinders 7 are fixed On the same cross bar 6, the two ends of the cross bar 6 vertically fix the vertical rods 5 respectively, and the turning rollers 19 are respectively installed on the two vertical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com