A Hole Coaxiality Processing Method for Special-shaped Box Parts of Gear Hobbing Machine

A special-shaped box and processing method technology, applied in the field of mechanical processing, can solve problems such as waste of manpower and material resources, lower production efficiency, and waste products, and achieve the effect of low cost and simple and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

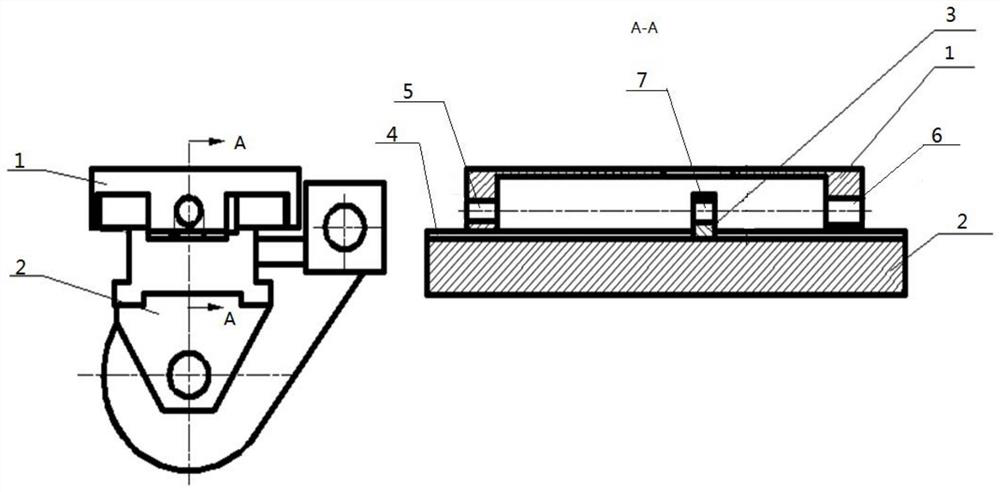

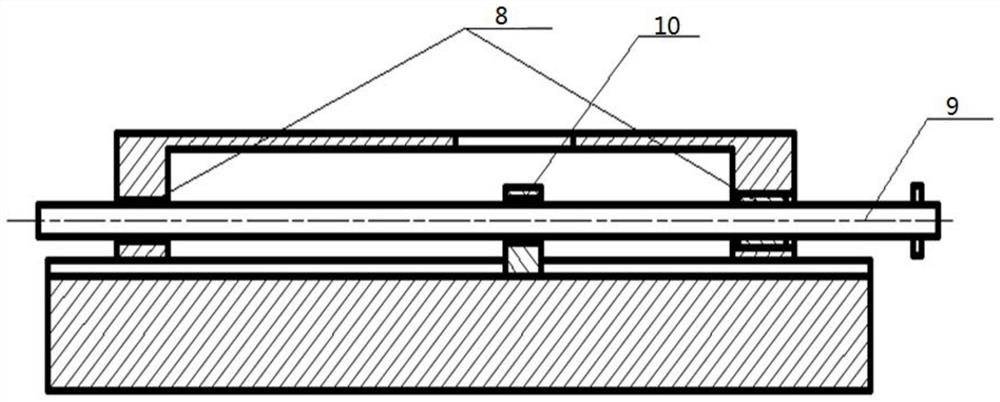

[0025] figure 1 It is a structural schematic diagram of the present invention, and the coaxiality processing method of hobbing machine special-shaped box parts in this embodiment includes the following steps:

[0026] S1: first process the tool holder 2 to ensure that the guide rail 4 of the tool holder is qualified;

[0027] S2: Install the nut holder 3 on the tool holder 2, and pre-process the hole III7 on the nut holder 3 by drilling, and the aperture of the pre-processed hole III7 is 1-5mm smaller than the designed aperture;

[0028] S3: Process the base 1, and process the hole I5 and the hole II6 at both ends of the base 1 by drilling first and then boring to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com