Hybrid power driving system and vehicle

A drive system and hybrid technology, applied in hybrid vehicles, fluid pressure actuation system components, motor vehicles, etc., can solve the problems of poor smoothness and frustration of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

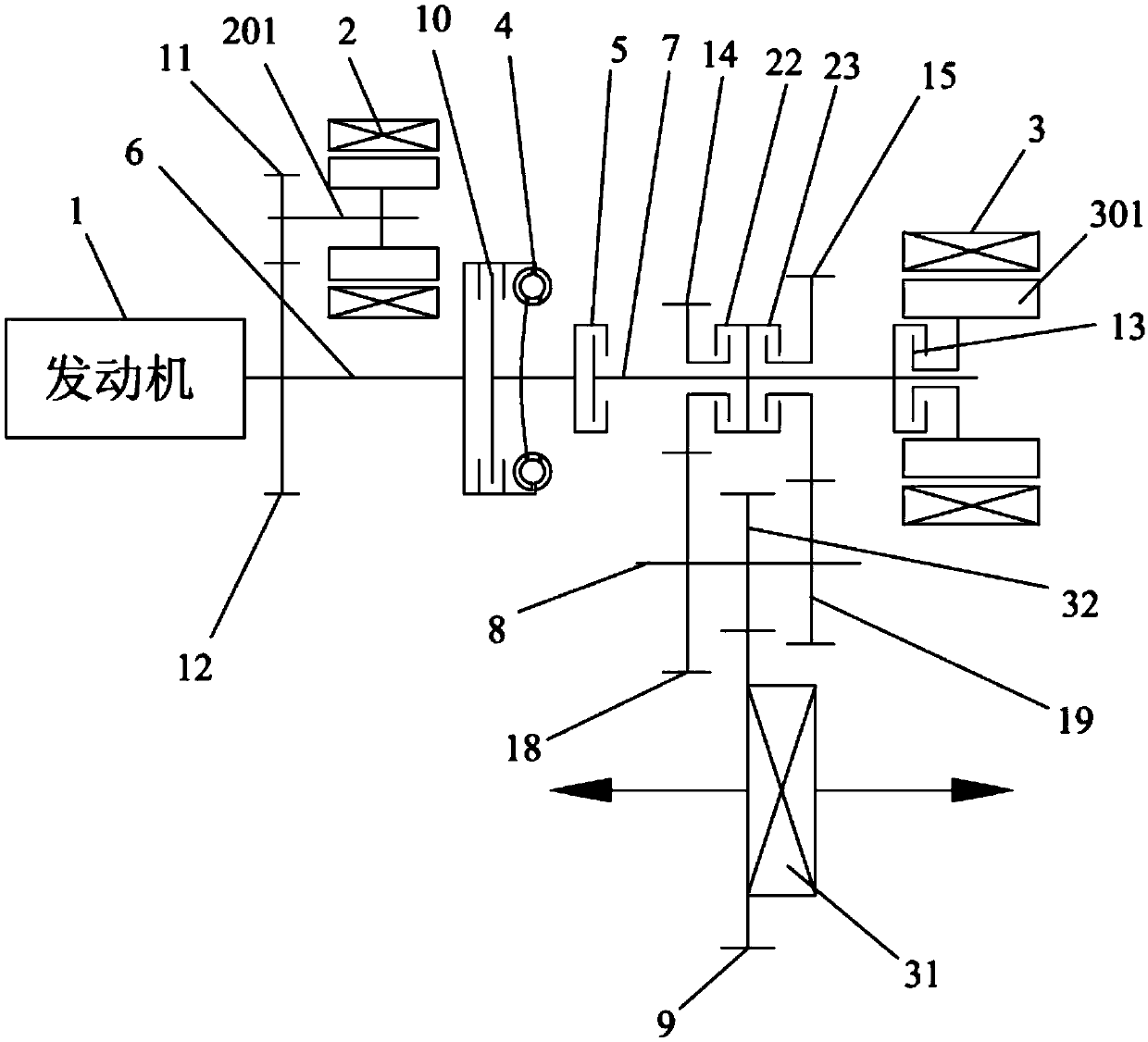

[0071] like figure 1 As shown, the hybrid drive system provided by the first embodiment of the present invention includes an engine 1, a first motor 2, a second motor 3, a torque converter 4, a first clutch 5, a second clutch 13, and an engine output shaft. 6 and a transmission, the transmission includes a transmission input shaft 7, a transmission output shaft 8, a transmission gear mechanism and a shift synchronization mechanism.

[0072] The transmission output shaft 8 is fixedly connected with an output gear 32 that meshes with the differential gear 9 . The differential gear 9 is provided on the housing of the differential 31 . The differential gear 9 rotates together with the housing of the differential 31 . In this way, the transmission output shaft 8 outputs power to the differential 31 .

[0073] The torque converter 4 is provided with a lock-up clutch 10 , and the shift synchronization mechanism includes a first gear clutch 22 and a second gear clutch 23 .

[0074...

no. 2 example

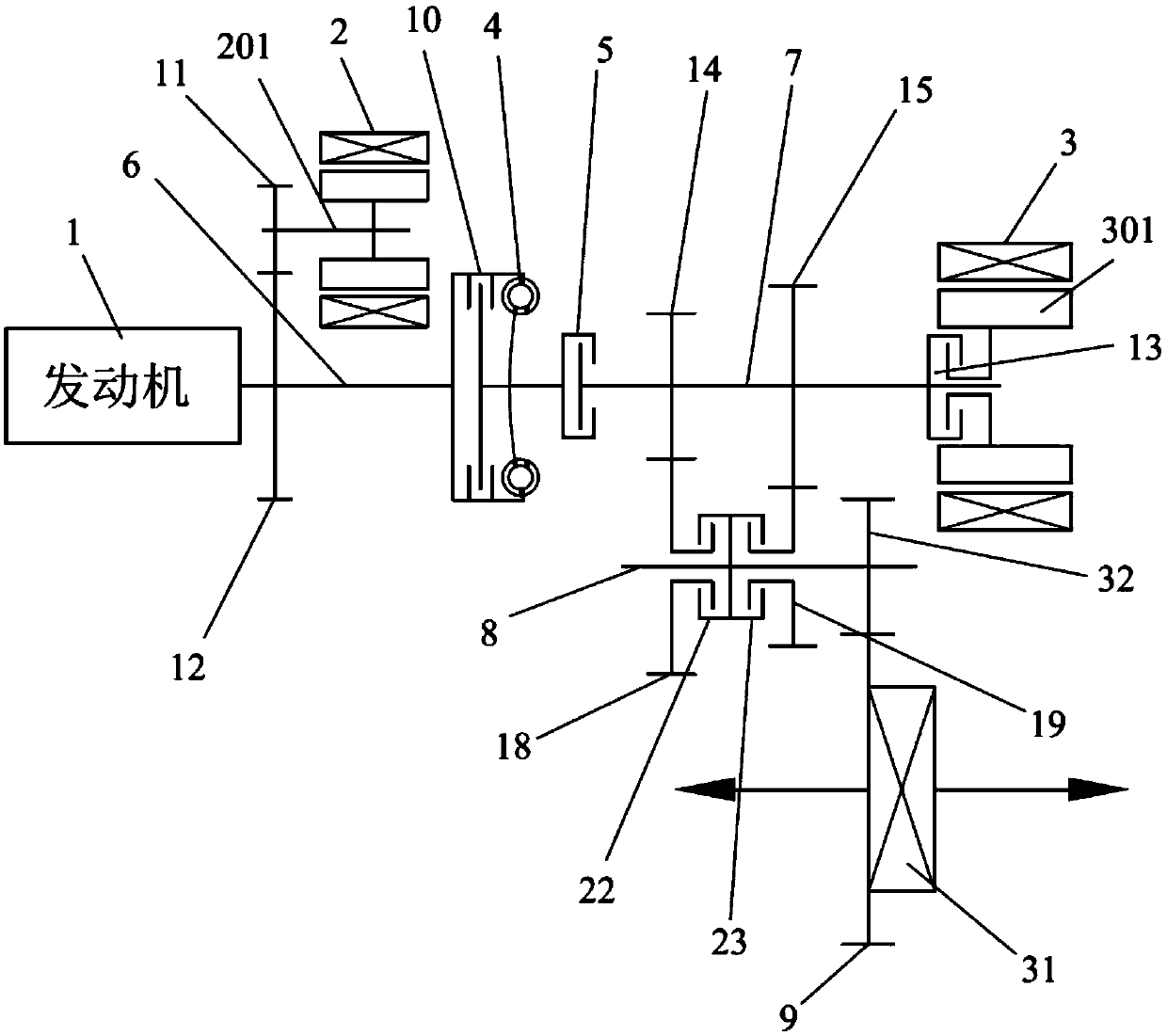

[0109] figure 2 Shown is the hybrid power system provided by the second embodiment of the present invention, which is different from the first embodiment in that the first gear driving gear 14 and the second gear driving gear 15 are fixed on the transmission input shaft 7 Above, the first gear driven gear 18 and the second gear driven gear 19 are idly sleeved on the transmission output shaft 8, and the first gear clutch 22 and the second gear clutch 23 are arranged on the on the transmission output shaft 8.

[0110] The first gear clutch 22 is selectively engaged or disengaged to control the engagement or disengagement of the first gear driven gear 18 with the transmission output shaft 8 , and the second gear clutch 23 is selectively engaged or disengaged. ground to engage or disengage to control the engagement or disengagement of the second gear driven gear 19 with the transmission output shaft 8 .

[0111] The first clutch 5, the first gear driving gear 14, the second gea...

no. 3 example

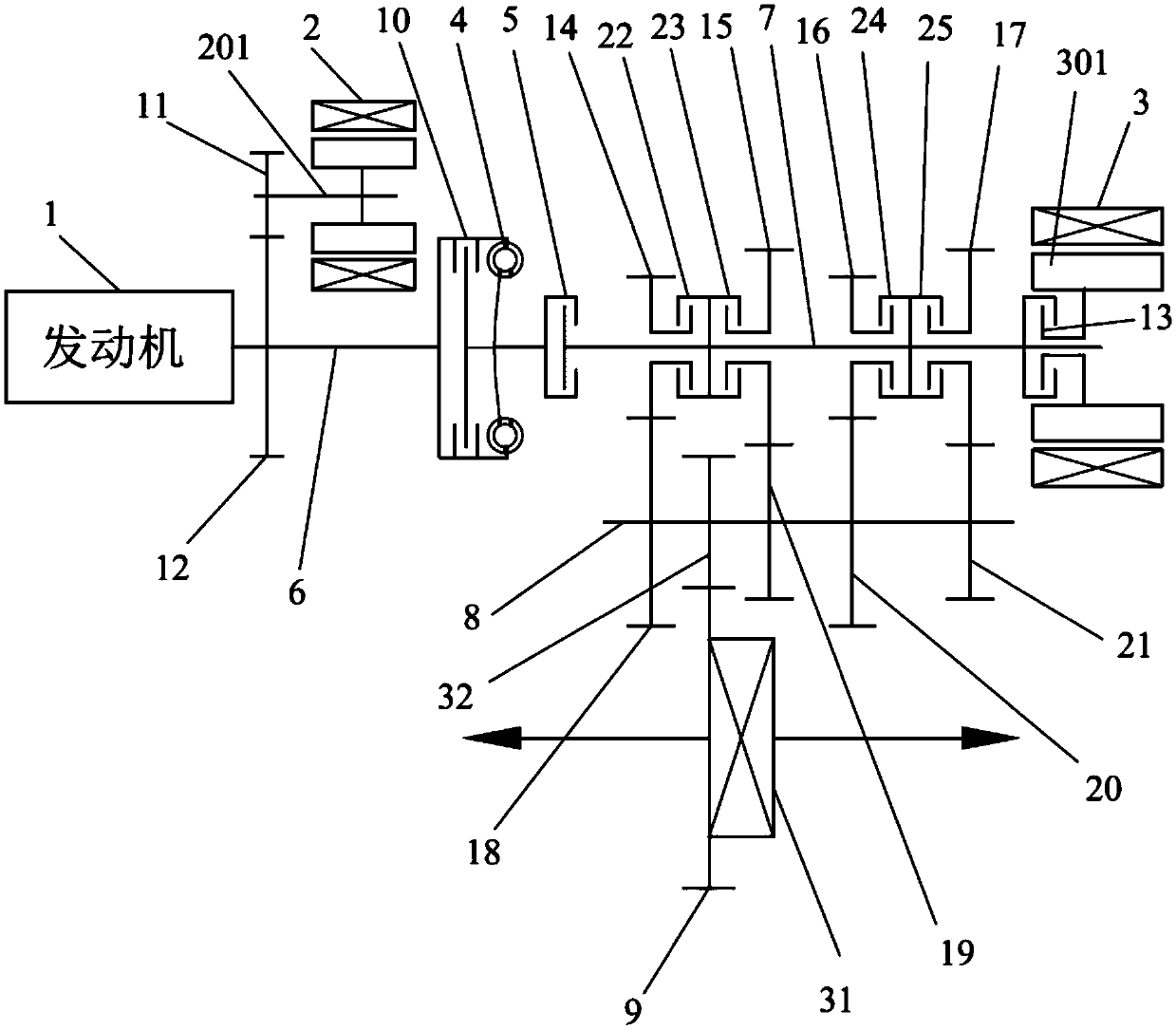

[0113] image 3 Shown is the hybrid power system provided by the third embodiment of the present invention, which is different from the first embodiment in that the number of gears is different. In the third embodiment, there are 4 sets of gears.

[0114] like image 3As shown, specifically, the plurality of gear driving gears include a first gear driving gear 14, a second gear driving gear 15, a third gear driving gear 16 and a fourth gear driving gear 17, and the plurality of gears are The gear driving gear includes a first gear driven gear 18, a second gear driven gear 19, a third gear driven gear 20 and a fourth gear driven gear 21. The first gear driving gear 14. The second gear driving gear 15, the third gear driving gear 16 and the fourth gear driving gear 17 are idle on the transmission input shaft 7, the first gear driven gear 18, the second gear The driven gear 19, the driven gear 20 of the third gear and the driven gear 21 of the fourth gear are fixed on the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com