Particle mixture and injection molded body

一种混合物、颗粒的技术,应用在化学仪器和方法、液晶材料等方向,能够解决成型体尺寸、外观影响、计量时间有偏差等问题,达到色调优异、计量稳定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0359]

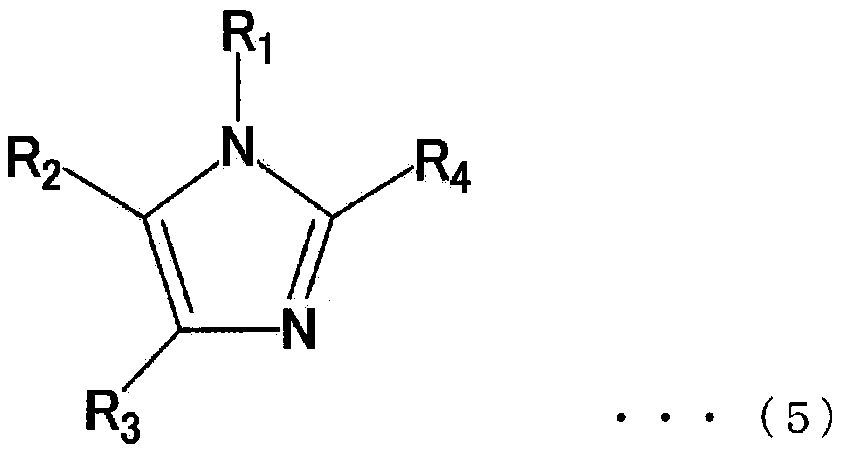

[0360] 994.5g (7.2 moles) of 4-hydroxybenzoic acid and 446.9g (2.4 moles) of 4,4'-dihydroxybiphenyl were put into the reactor with stirring device, torque meter, nitrogen gas introduction pipe, thermometer and reflux cooler , 299.0 g (1.8 moles) of terephthalic acid, 99.7 g (0.6 moles) of isophthalic acid and 1347.6 g (13.2 moles) of acetic anhydride, 0.2 g of 1-methylimidazole was added as a catalyst, and the reaction was fully replaced with nitrogen inside the device.

[0361] Next, while stirring under a nitrogen stream, the temperature was raised from room temperature to 150° C. over 30 minutes, and the same temperature was maintained and refluxed for 30 minutes.

[0362] Then, 2.4 g of 1-methylimidazole was added, while the by-product acetic acid and unreacted acetic anhydride were distilled off, the temperature was raised from 150°C to 320°C over 2 hours and 50 minutes, and the contents were kept at 320°C for 30 minutes. , let it cool to room temperature.

...

Embodiment 1~7、 comparative example 1~4

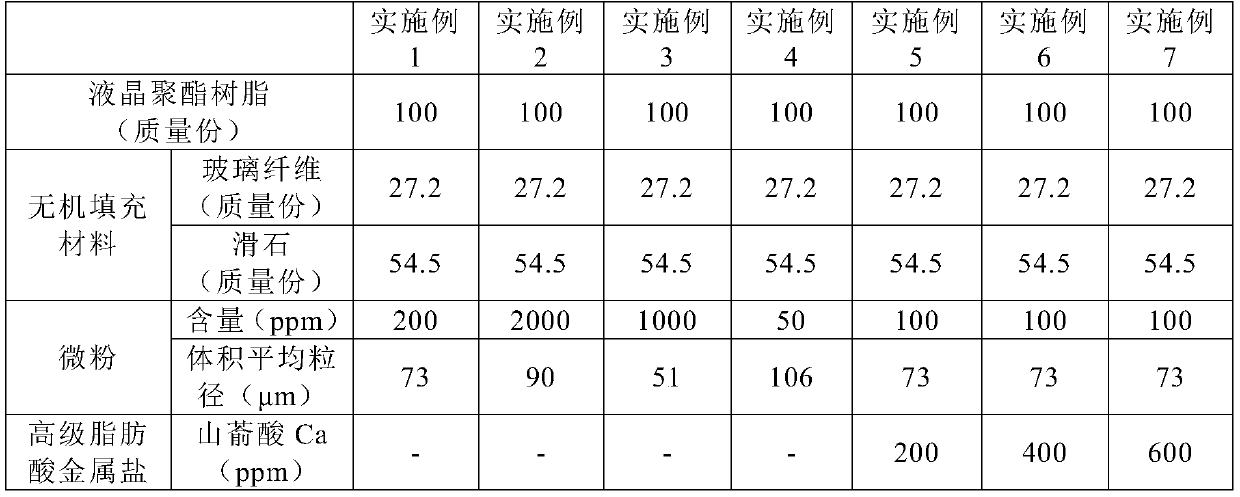

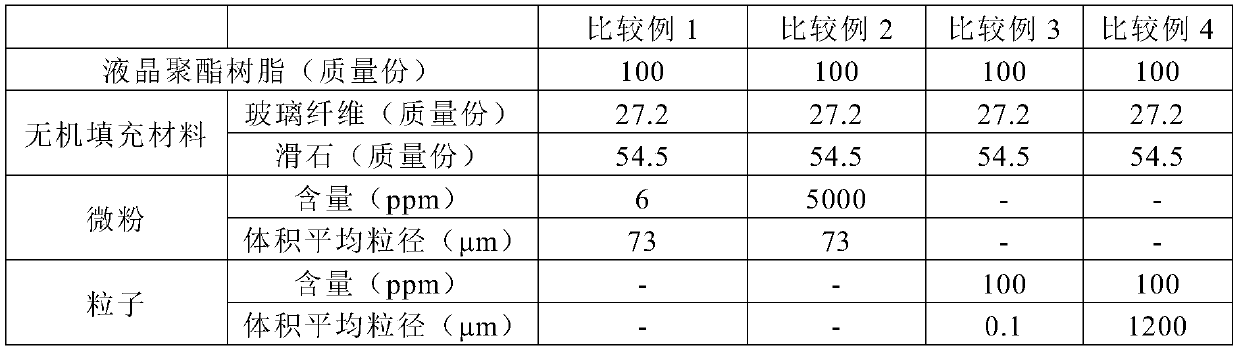

[0372]First, using a twin-screw extruder (manufactured by Ikegai Iron Works Co., Ltd. (Ikegai Iron Works Co., Ltd., "PCM-30")), the liquid crystal polyester resin and the inorganic filler were mixed in the cylinder at the ratios shown in Table 1 and Table 2. The melt-kneaded product was obtained by melting and kneading under the conditions of a temperature of 340° C. and a screw rotation speed of 150 rpm. Then, the obtained melt-kneaded product was discharged into strands through a circular discharge port, cooled, and then pelletized to obtain rough pellets of the liquid crystal polyester resin composition.

[0373] In addition, pellets of the liquid crystal polyester resin composition were produced while using a water-sealed vacuum pump (manufactured by Shinko Seiki Co., Ltd., "SW-25") to degas the vacuum outlet of the twin-screw extruder. .

[0374] Then, using a rotary particle separator with a sieve size of 2 mm (rotary particle separator "M2 type / ST" manufactured by Kubo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com