Snowfield camouflage net white coating and preparation method thereof

A camouflage net, white technology, applied in coatings, protective equipment, camouflage devices, etc., can solve the problems of low UV reflectivity, camouflage performance, flame retardancy and weather resistance of snow camouflage equipment, and achieve good camouflage ability , Improve the effect of high emissivity and single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Use low-emissivity base material: polyester aluminized cloth (aluminized on one side, low-emissivity base material on one side, emissivity of low-emissivity surface is 0.1).

[0035] (2) Preparation of white camouflage paint: Use 75 parts of polyester resin (TX-354), dissolve in a mixed solvent of 110 parts of butyl acetate and 62 parts of xylene, add 2 parts of dispersant (904S), adhesion promoter 1.2 part, stirred in a high-hardness stainless steel dispersing device at a stirring rate of 800rmp / min for 30min, under continuous stirring, slowly added 120 parts of micron-sized magnesium oxide (SYM-98-1) and 120 parts of nano-sized magnesium oxide, after adding, Continue stirring for 10 minutes at a stirring rate of 500rmp / min. After stirring evenly, grind the dispersed materials with a horizontal sand mill. The filling rate of the grinding medium of the sand mill is 0.82. The material of the grinding medium is 95 zirconium beads, and the diameter of the zirconium bead...

Embodiment 2

[0053] Use low-emissivity substrate: PET aluminized film (double-sided low-emissivity substrate, emissivity 0.01-0.03);

[0054] Implementation according to step in embodiment 1, formula is as shown in the following table:

[0055] Coating Formulation Low emissivity surface white coating / flame retardant surface coating flame retardant coating FS-2050 (50% solid content) 120 copies 120 copies Butyl acetate 110 copies 50 copies Xylene 62 copies 50 copies Micron magnesium oxide SYM-98-1 120 copies / Nano Magnesium Oxide 120 copies / Decabromodiphenyl ether / 111 copies Antimony trioxide / 37 copies Dispersant 904S 2 copies 2 copies Adhesion promoter KH-550 1.2 parts / Curing agent TPA-100SB 6 servings 8 servings Drier T12 0.1 part 0.1 part

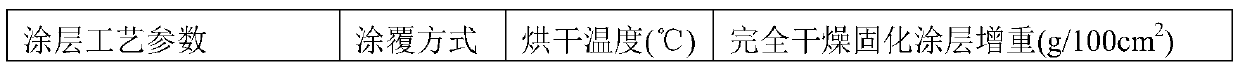

[0056] The process parameters of each coating are shown in the table below:

[0057]

[0058]

[0059] The test result of emb...

Embodiment 3

[0062] Use low-emissivity substrate: polyester aluminized cloth (aluminized on one side, low-emissivity substrate on one side, emissivity of low-emissivity surface is 0.1).

[0063] Implementation according to step in embodiment 1, formula is as shown in the following table:

[0064] Coating Formulation Low emissivity surface white coating / flame retardant surface coating flame retardant coating TX-354 (80%) 75 copies 75 copies Butyl acetate 110 copies 50 copies Xylene 62 copies 50 copies Micron magnesium oxide SYM-98-1 120 copies / Nano Magnesium Oxide 120 copies / Decabromodiphenyl ether / 111 copies Antimony trioxide / 37 copies Dispersant 904S 2 copies 2 copies Adhesion promoter KH-550 1.2 parts / Curing agent TPA-100SB 6 servings 8 servings Drier T12 0.1 part 0.1 part

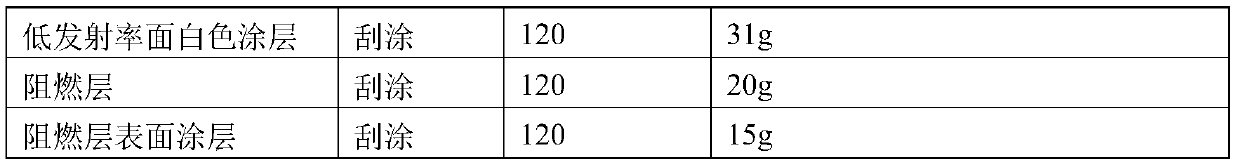

[0065] The process parameters of each coating are shown in the table below:

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com