Melt-blown non-woven fabric production raw material pre-treating process

A melt-blown non-woven fabric and pretreatment technology, applied in the directions of melt spinning, fiber processing, non-woven fabrics, etc., can solve the problems of reduced work efficiency, reduced melting degree of molten polymer, poor thermal insulation effect of thermal insulation structure, etc. Achieve the effect of improving work efficiency, simplifying work process, and improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

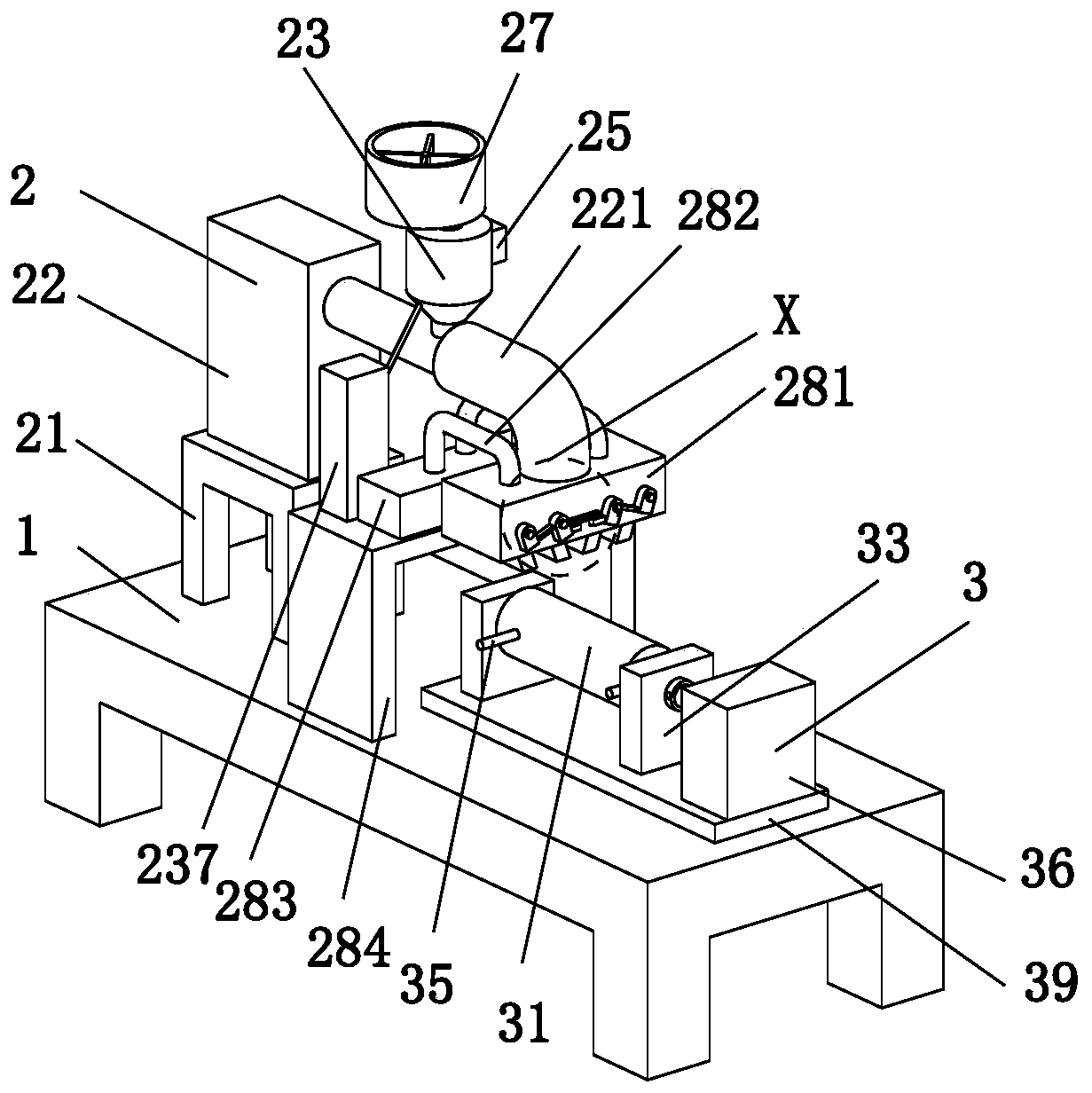

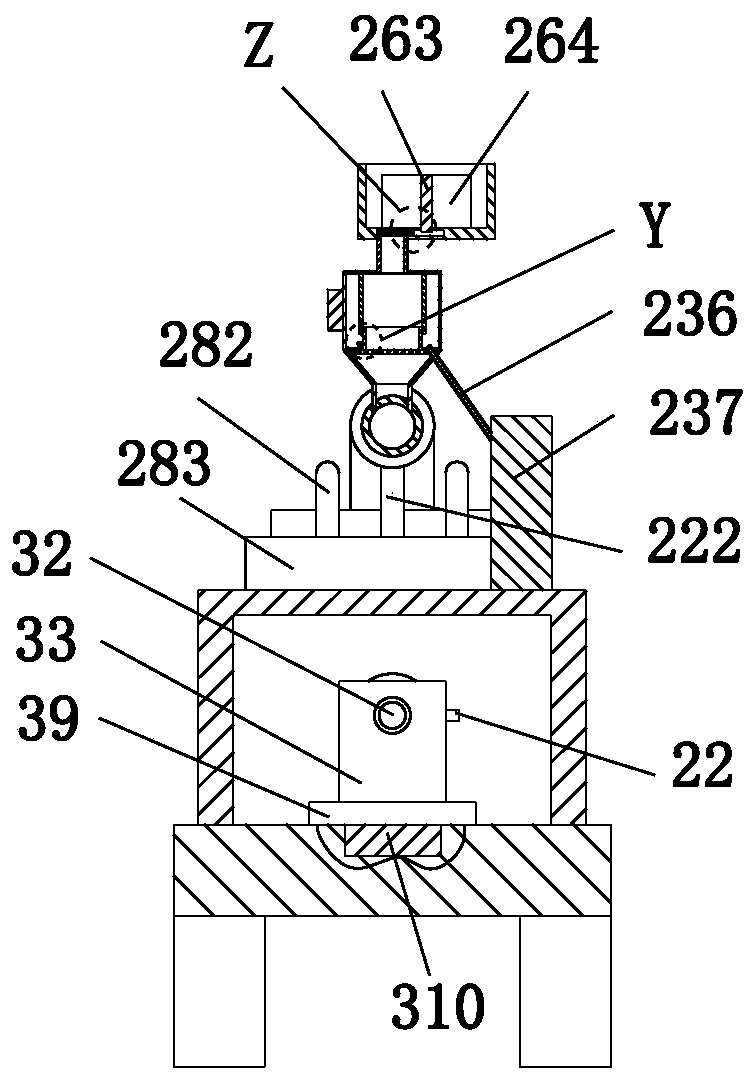

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

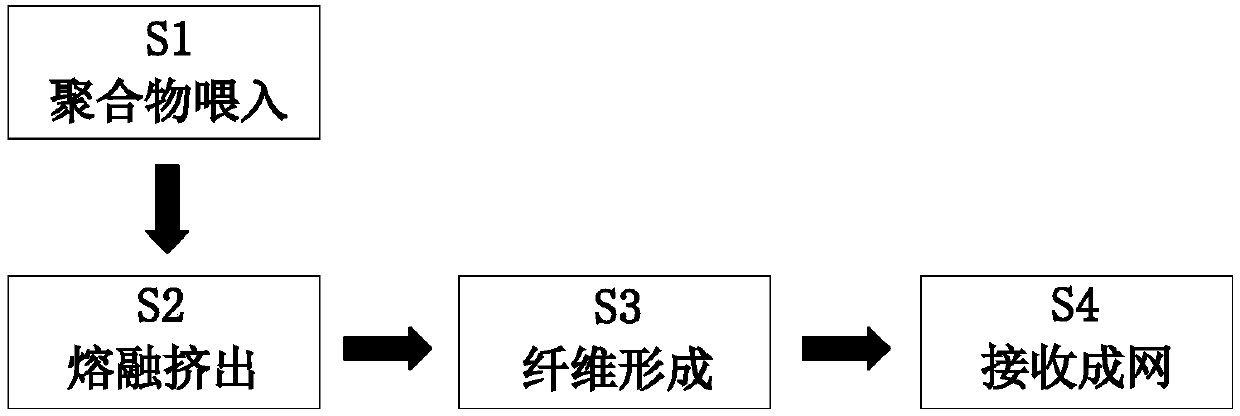

[0040] like Figure 1 to Figure 11 As shown, a raw material pretreatment process for the production of melt-blown non-woven fabrics uses a raw material pre-treatment device for the production of melt-blown non-woven fabrics. Mechanism 2 and receiving mechanism 3, when using the above-mentioned melt-blown non-woven fabric production raw material pretreatment device to pretreat the melt-blown non-woven fabric production raw materials, the specific pretreatment process is as follows:

[0041] S1. Polymer feeding: the polymer is fed into the feed pipe 27 manually, and the polymer enters the reactor 23 along the connecting pipe 26;

[0042] S2, melt extrusion: the reactor 23 melts the polymer, controls the melting time and temperature through the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com