Clamping groove type steel wood combined node and mounting method thereof

A combination of steel and wood, slot-type technology, applied in the direction of construction, building structure, etc., to achieve the effect of fast construction, less parts, and easy theoretical calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

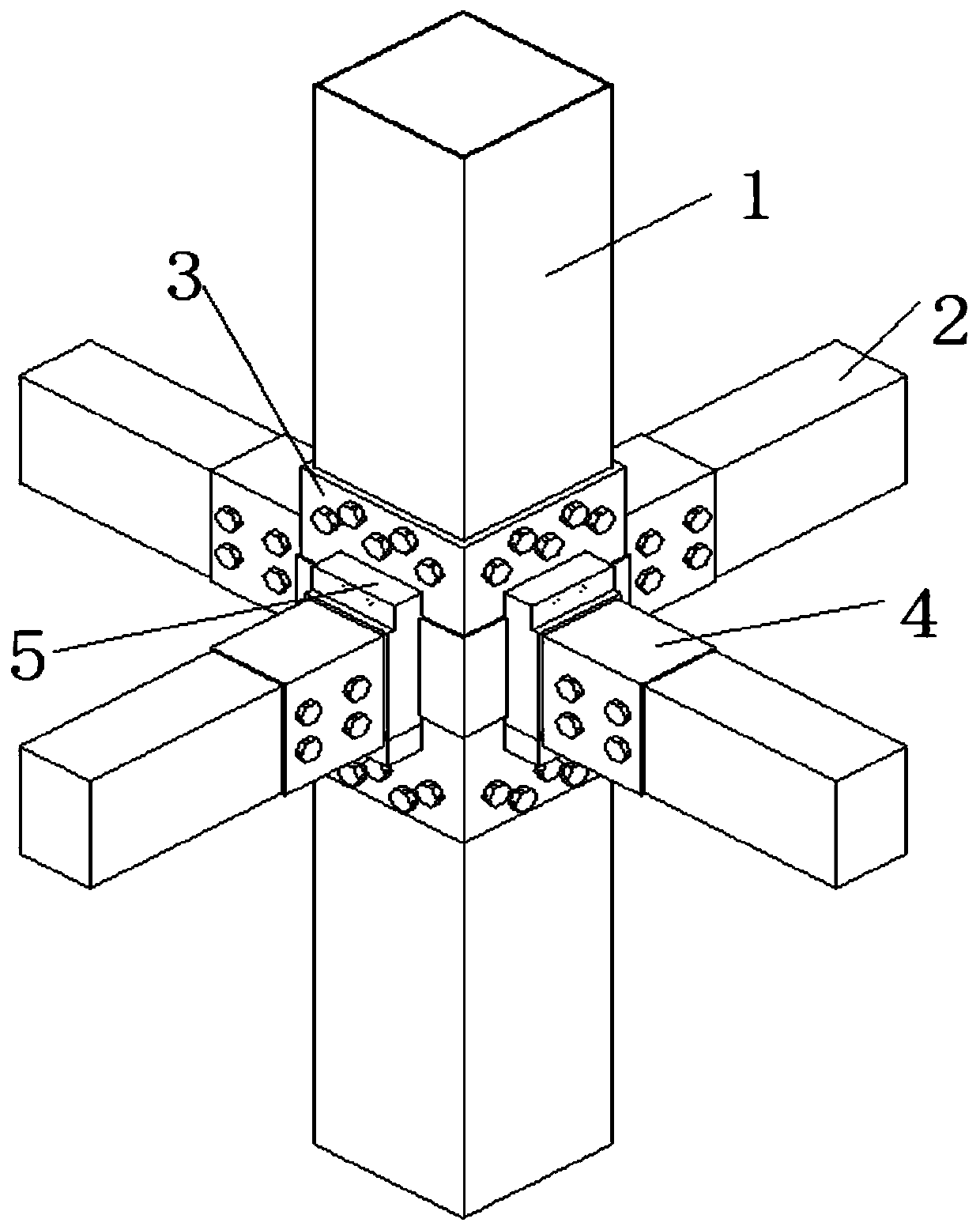

[0037] Such as figure 1 As shown, the grooved steel-wood composite node of the present invention includes a square wooden column 1 and a wooden beam 2, the wooden column is an FRP wooden column, and the surface of the wooden column is wrapped with FRP cloth to enhance the mechanical properties of the wooden column; it also includes The central steel pipe 3, the beam end steel sleeve 4 and the external free sleeve 5, the upper and lower wooden columns are connected through the central steel pipe, the wooden beam is connected to the central steel pipe 3 through the beam end steel sleeve 4, and the external free sleeve 5 is covered between the central steel pipe 3 and the beam end steel sleeve 4 Connect outside the node.

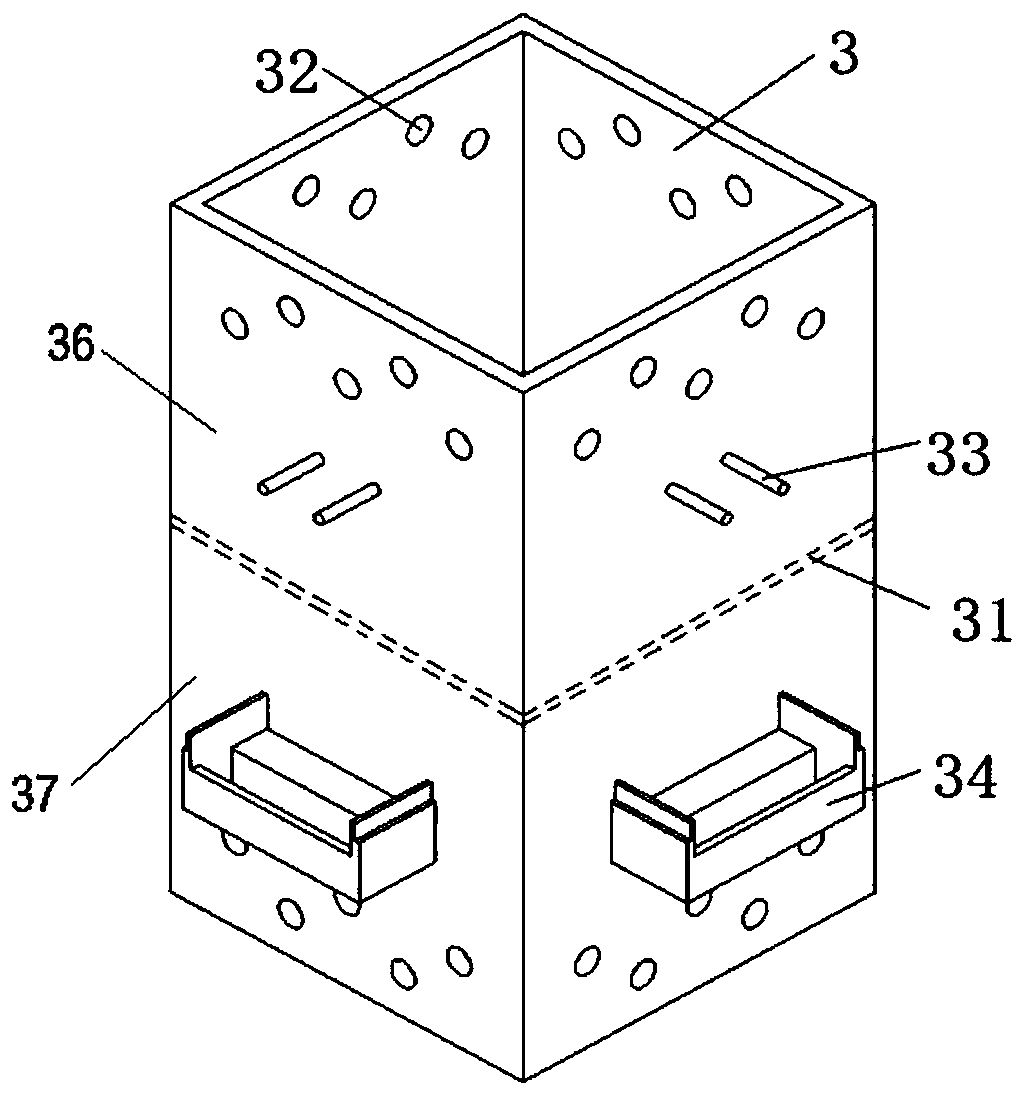

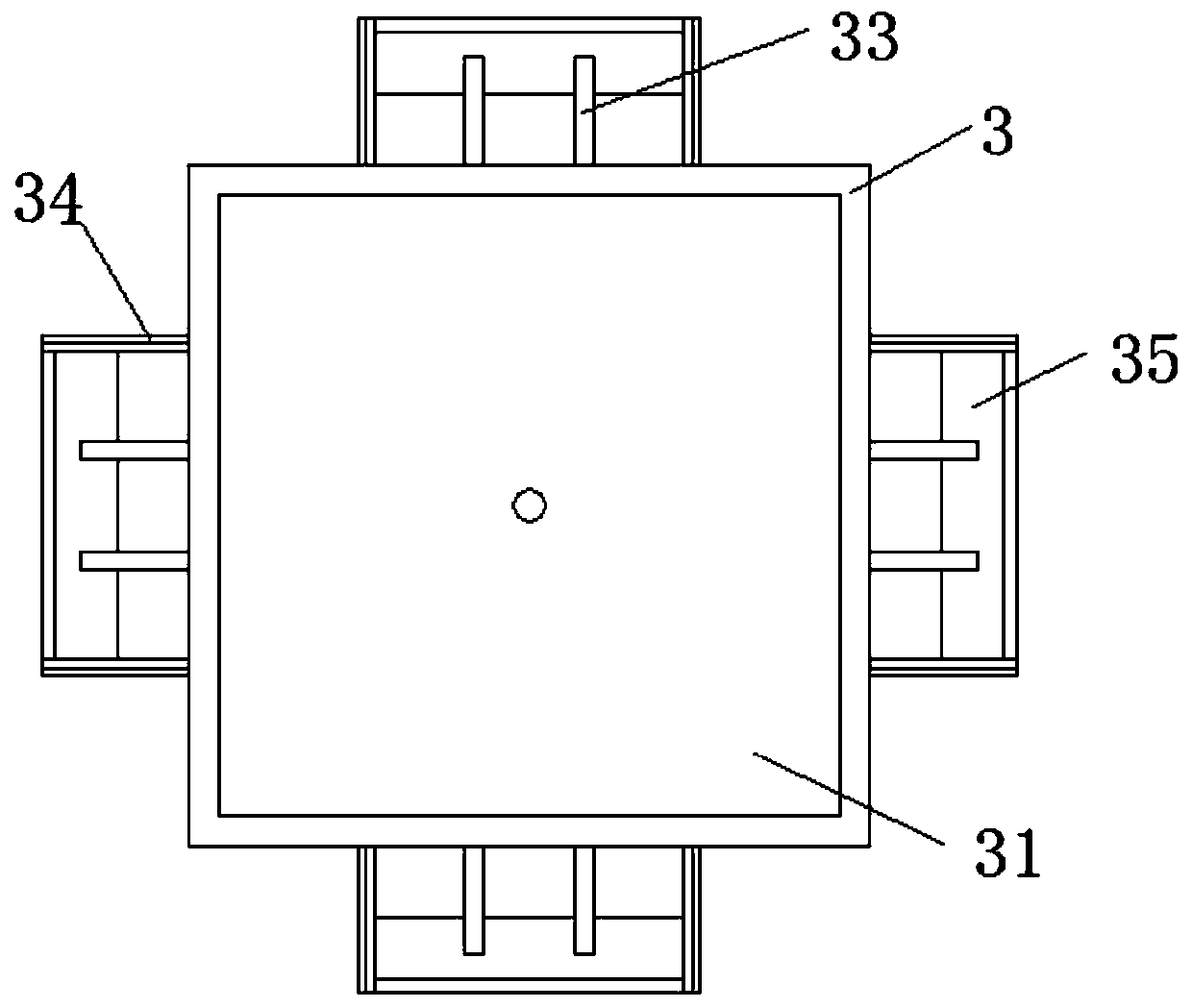

[0038] Such as Figure 2-3 As shown, a steel plate 31 is arranged inside the central steel pipe 3, and the steel plate 31 divides the interior of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com