Full-automatic function test method and device for new energy automobile controller

A technology for new energy vehicles and functional testing, applied in general control systems, control/regulation systems, electrical testing/monitoring, etc., can solve problems such as difficulty in meeting real-time testing requirements, difficulty in testing new energy vehicles, and complex electromagnetic environments , to improve test efficiency and intelligence, improve functional test performance, and achieve the effect of fault location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

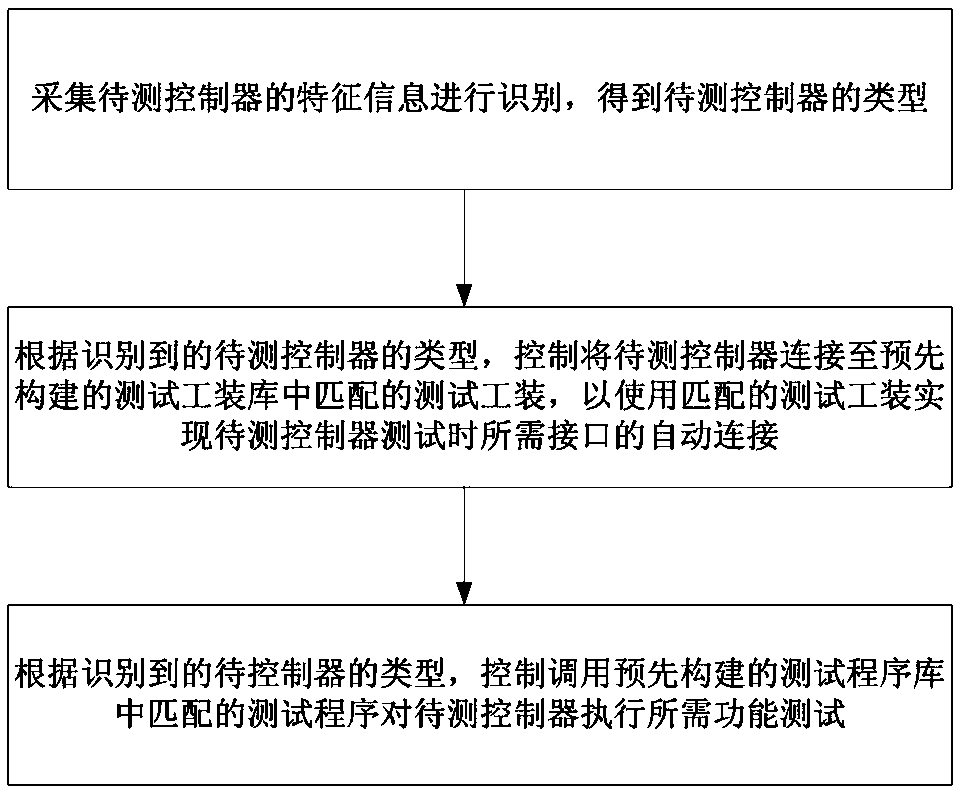

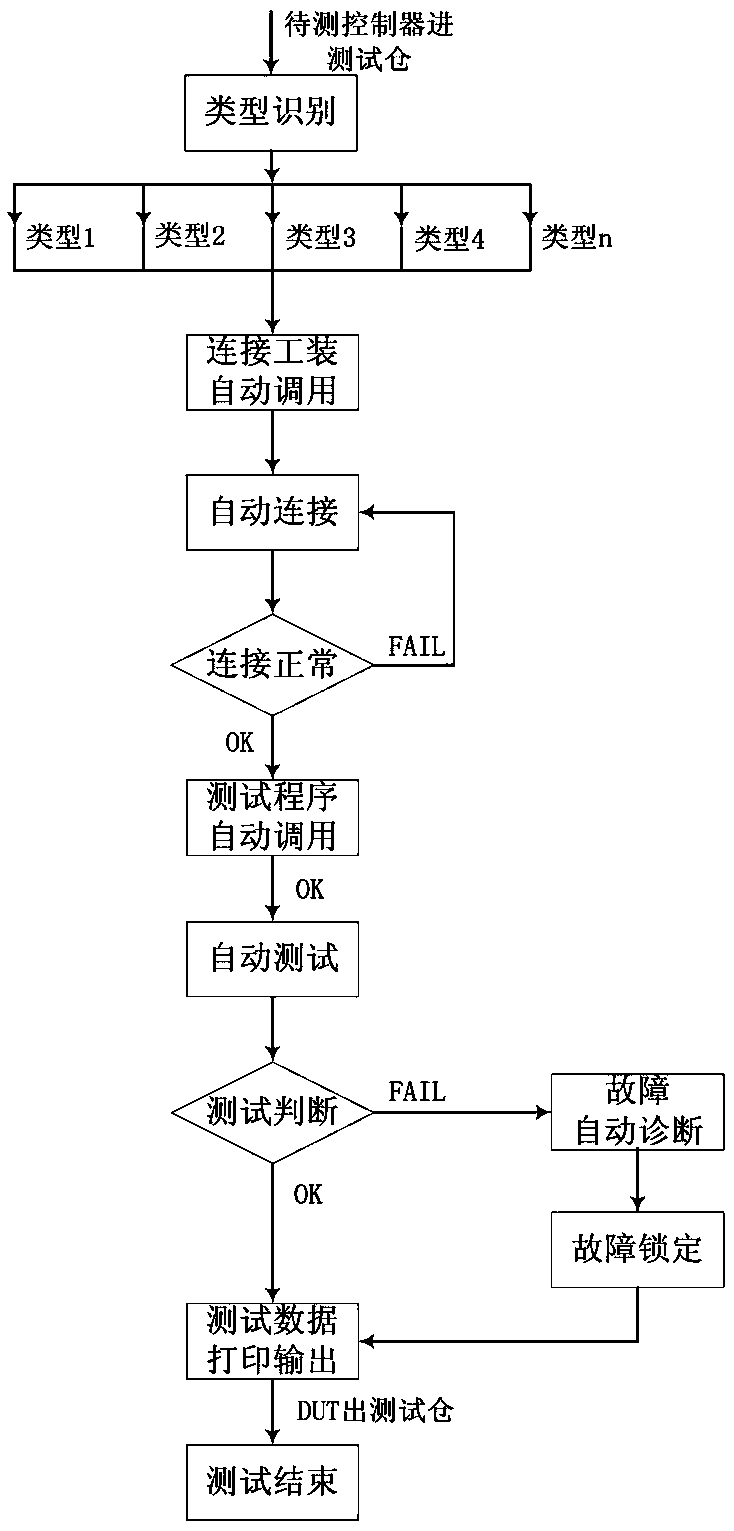

[0055] Such as Figure 1~4 As shown, the steps of the fully automatic functional testing method for the new energy vehicle controller in this embodiment include:

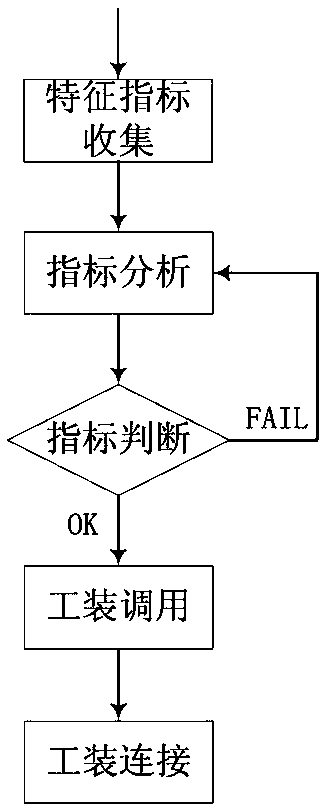

[0056] S1. Type automatic identification: collect the characteristic information of the controller to be tested for identification, and identify the type of the controller to be tested;

[0057] S2. Tool automatic call: according to the identified type of the controller to be tested, control the connection of the controller to be tested to the matching test tool in the pre-built test tool library, so as to use the matching test tool to realize the test of the controller to be tested Automatic connection of required interfaces;

[0058] S3. Functional test automatic execution: according to the identi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com