Cylindrical super capacitor module structure and assembling method thereof

A supercapacitor module, cylindrical technology, applied in the manufacture of hybrid/electric double layer capacitors, multiple hybrid/electric double layer capacitors, hybrid boxes/shells/packages, etc., can solve the problem of difficult assembly and inconvenient maintenance of supercapacitors And other problems, to achieve the effect of easy assembly and maintenance, improve current passing capacity, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

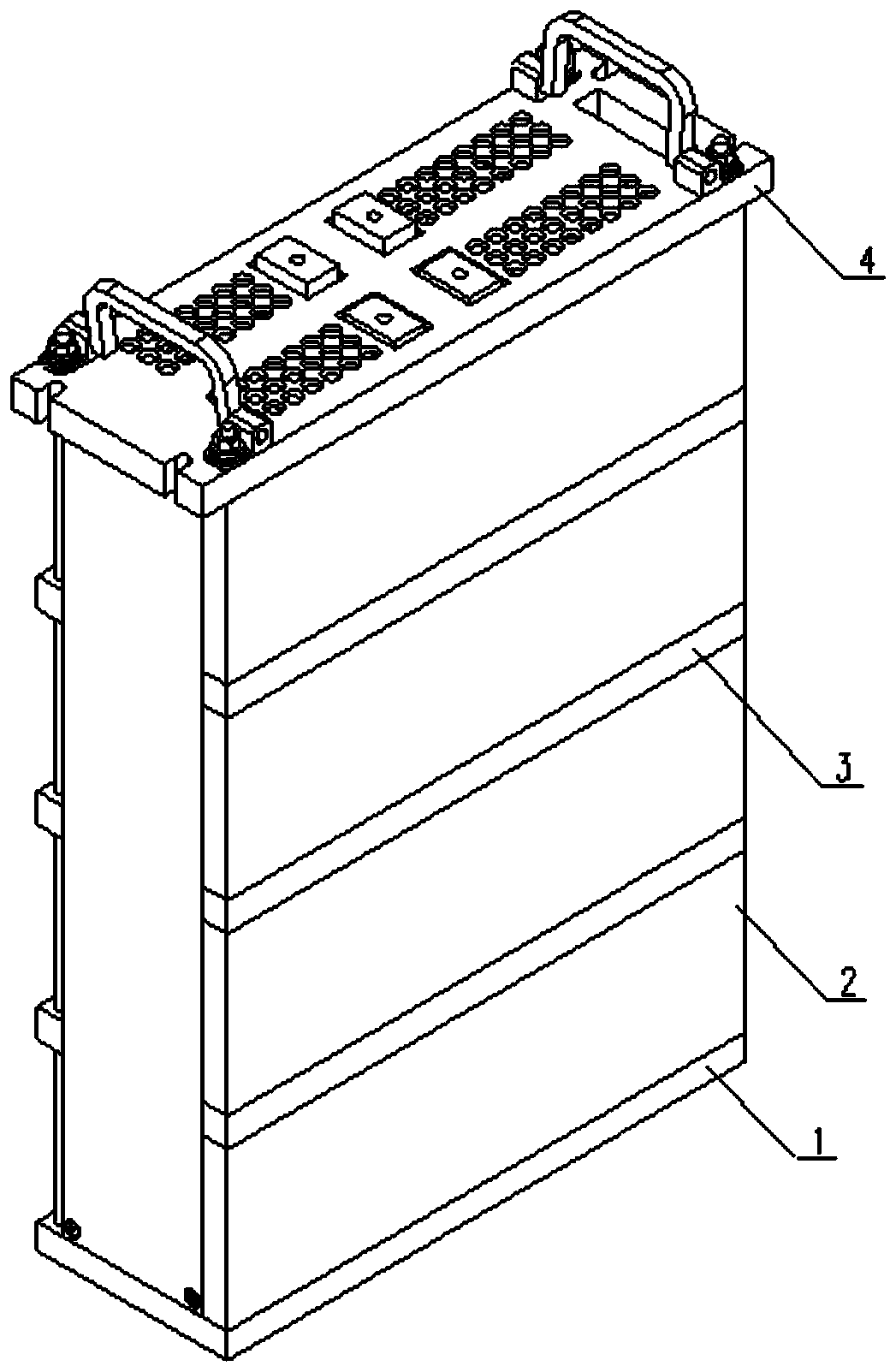

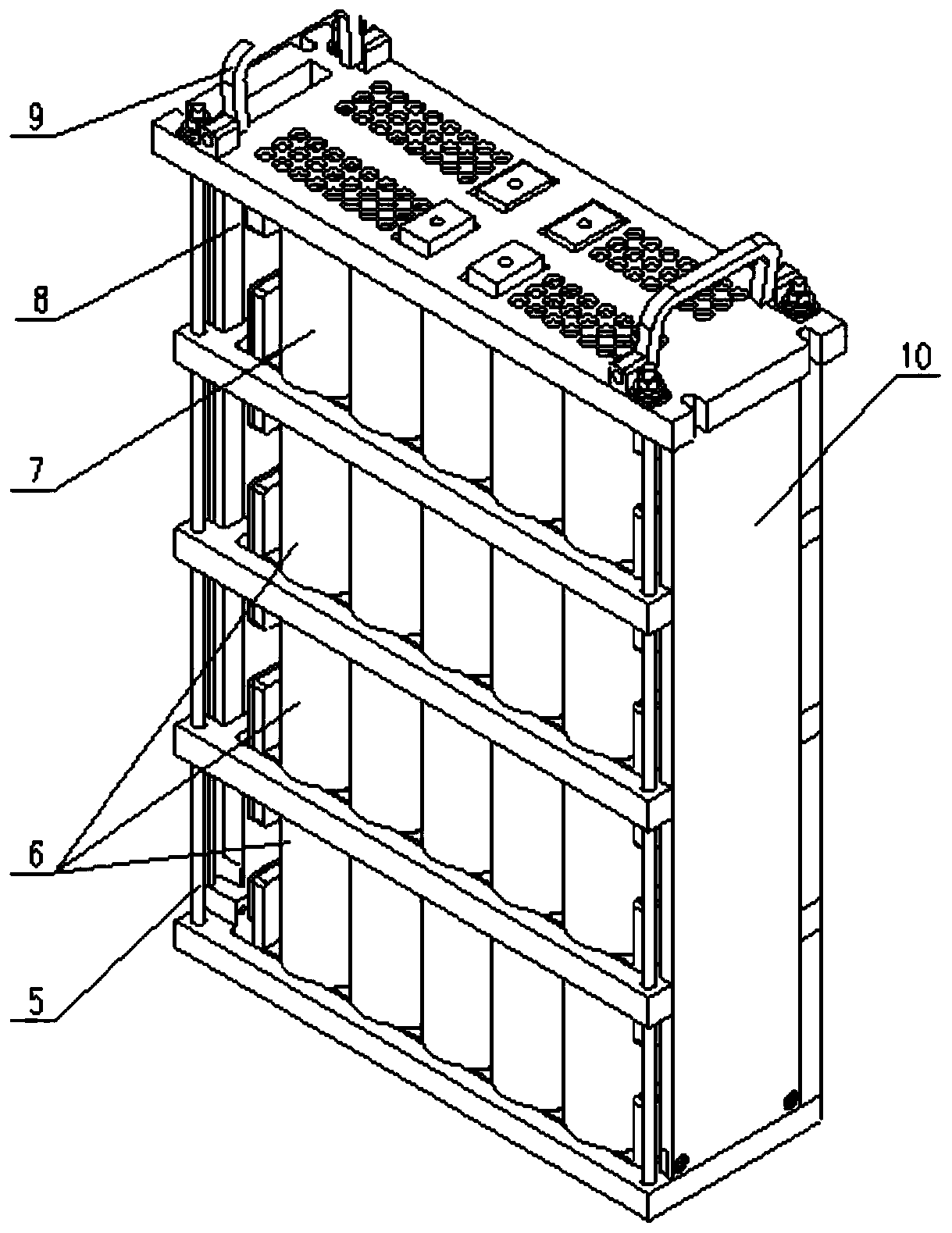

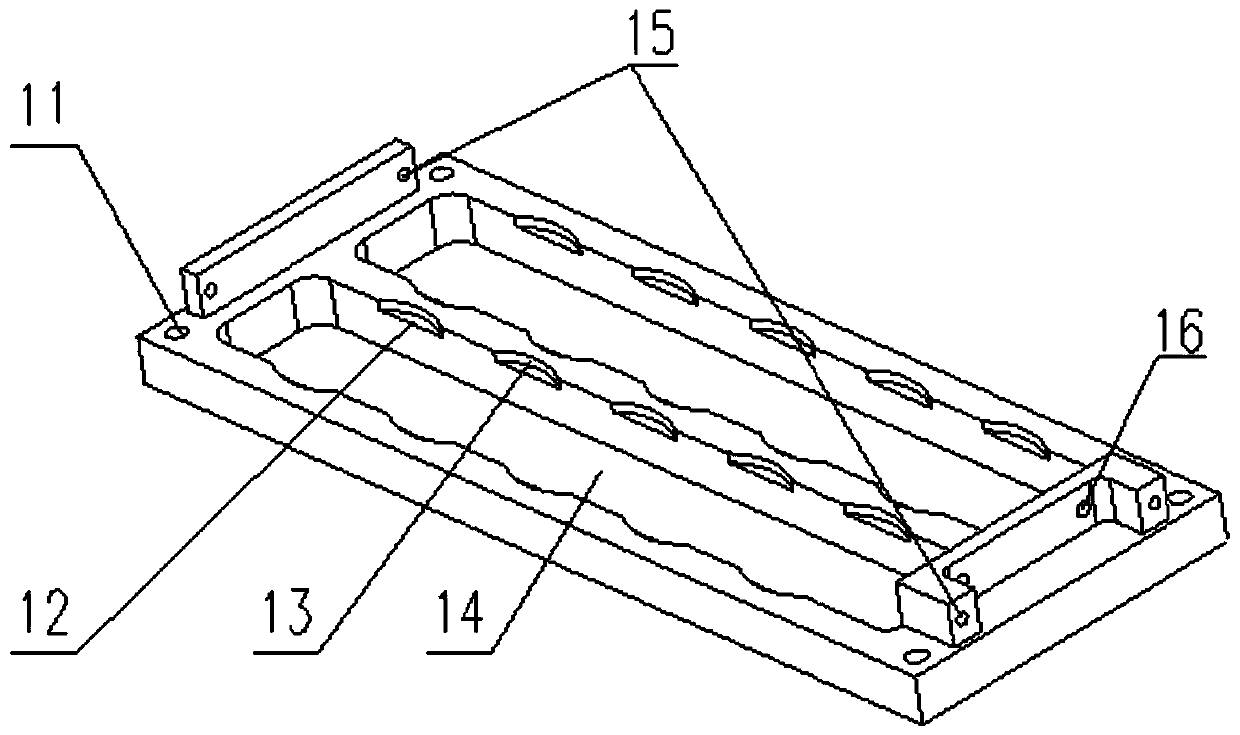

[0067] Such as Figure 1-Figure 18 As shown, an embodiment of the cylindrical supercapacitor module structure of the present invention includes a bottom plate 1, a side plate 2, a middle partition 3, a top plate 4, a long screw 5, a capacitor parallel assembly 6, a top layer capacitor parallel assembly 7, an equalization unit 8, Handle assembly 9, movable cover 10, bottom plate 1, side plate 2, intermediate partition 3, top plate 4, and movable cover 10 are all made of composite insulating materials, and multiple partitions are set between the bottom plate 1 and the top plate 3 Board 3, so that a multi-layer storage space is formed between the bottom board 1 and the top board 4, and multiple rows of capacitor parallel components 6 or top layer capacitor parallel components 7 are placed in each layer of storage space, and side plates are symmetrically installed on both sides of each layer of capacitor parallel components 2. The bottom plate 1, side plate 2, middle partition 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com