Ceramic electric kettle

An electric kettle and ceramic technology, applied in the field of ceramic processing, can solve the problems of poor heating effect of all-ceramic electric kettle, undeveloped all-ceramic electric kettle, and thermal conductivity not as good as stainless steel, etc., and achieve good strength, ensure strength, and ensure heating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

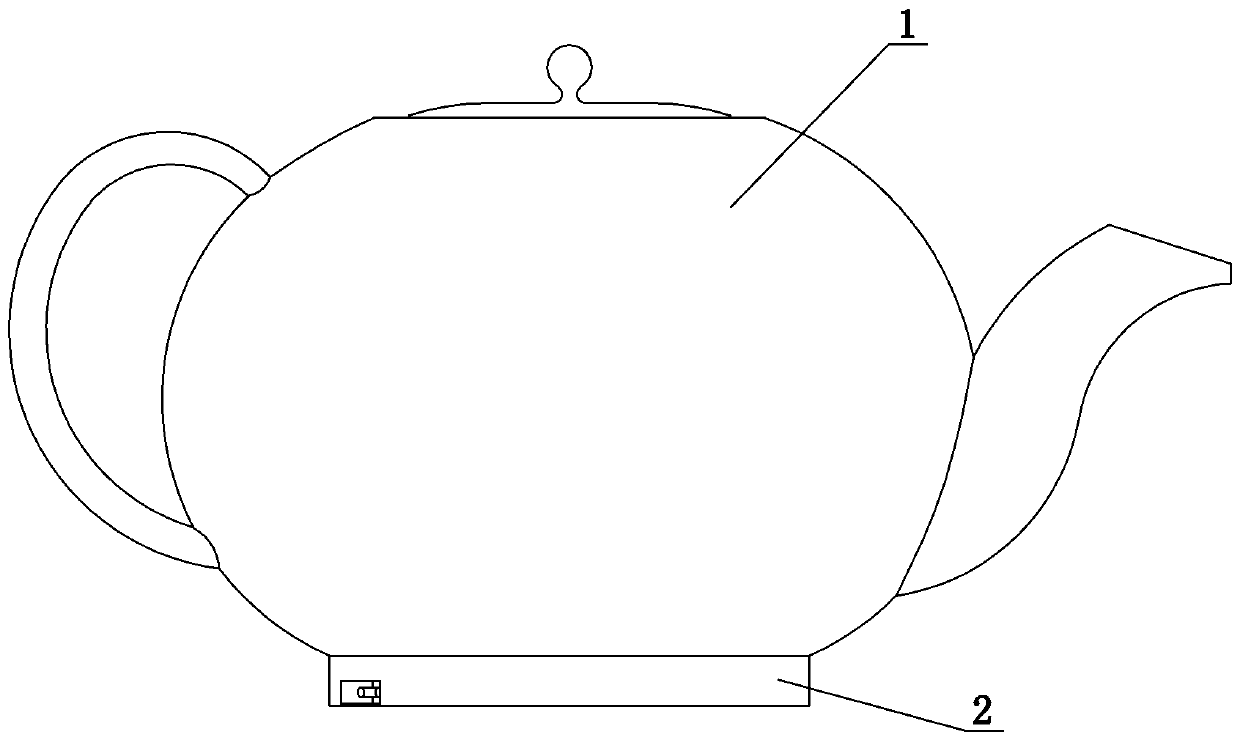

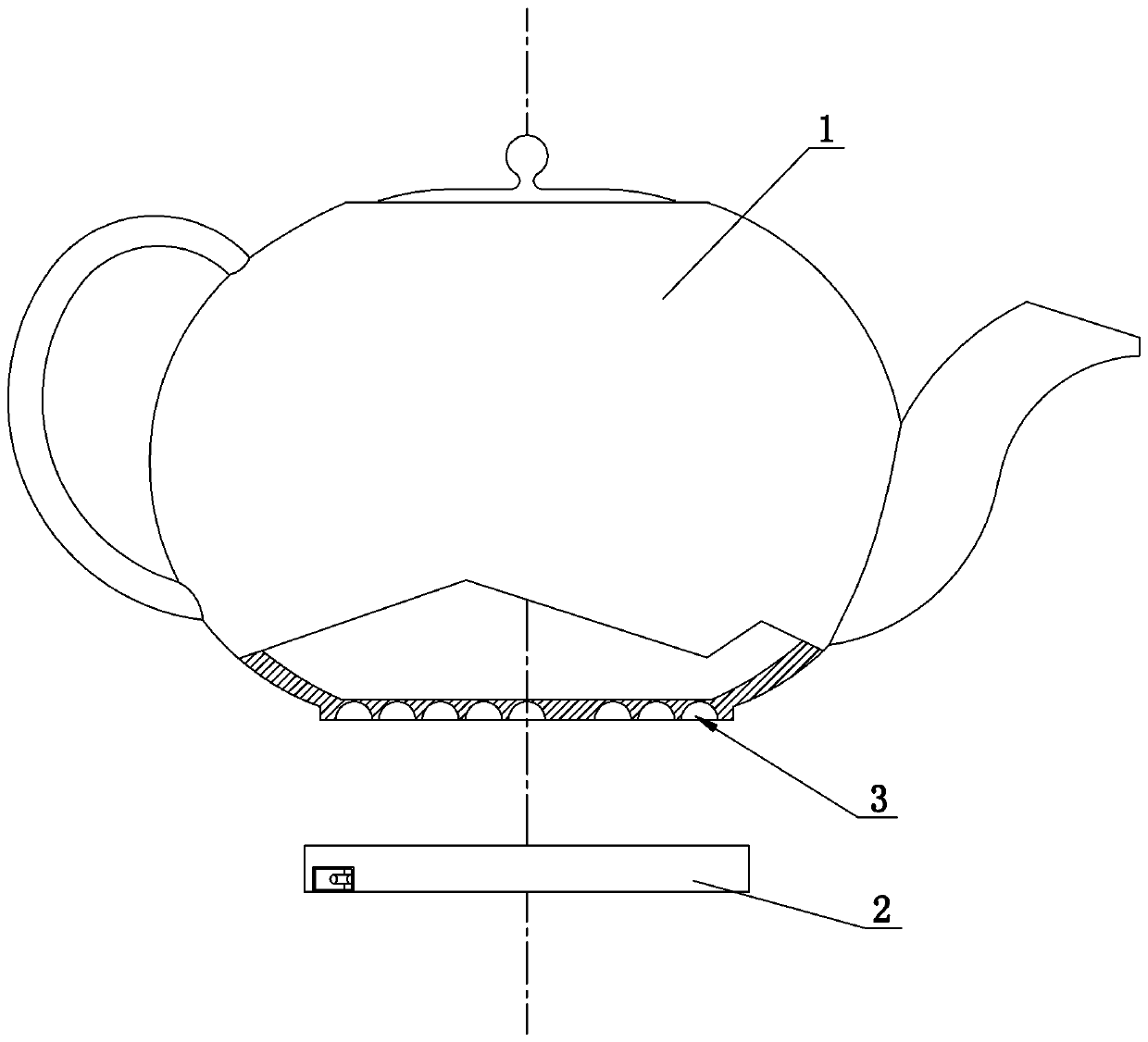

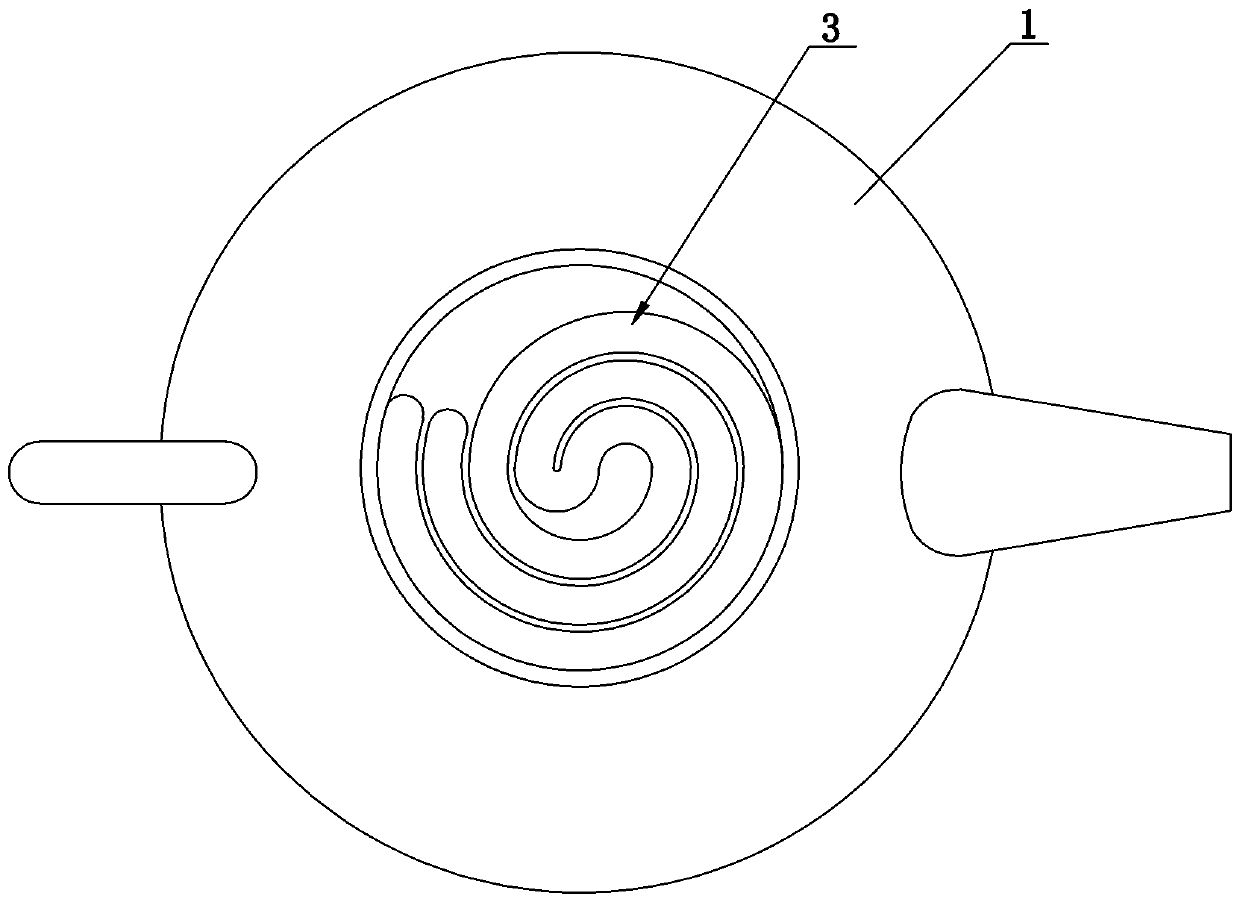

[0022] refer to Figure 1 to Figure 6 , a ceramic electric kettle, comprising a ceramic kettle body 1, a heat pipe 4 and a heat insulating bottom cover 2. Wherein, the heat pipe 4 is generally in a spiral shape, and the heat pipe 4 is fixedly installed on the heat insulating bottom cover 2 and is electrically connected to the plug 24 on the heat insulating bottom cover 2 . The heat insulating bottom cover 2 is fixedly installed on the bottom surface of the ceramic kettle body 1 through common connection methods such as superglue or screws. The cross-sectional profile of the installation groove 3 is semicircular, and the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com