Reciprocating stirring type SCR reactor flue gas flow equalizing device and working method thereof

An SCR reactor, stirring technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of insufficient ammonia reaction, large unevenness of the tail flow field, and reduced denitration rate. The effect of uniform and stable airflow field, reduction of ammonia escape level, and reduction of ammonia liquid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

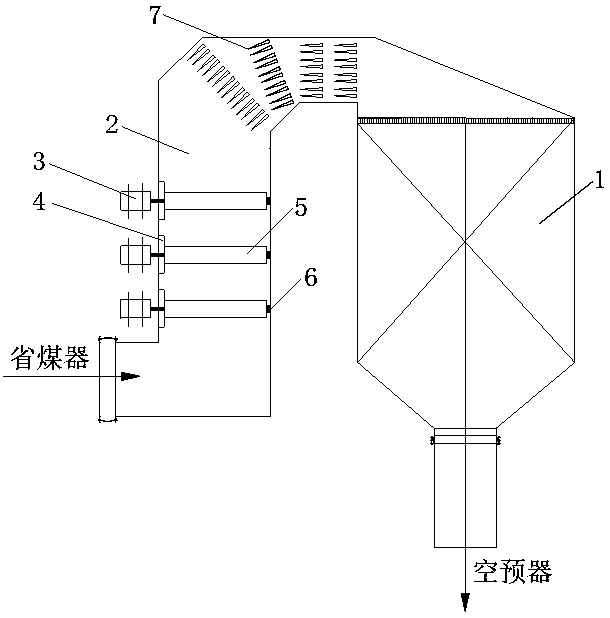

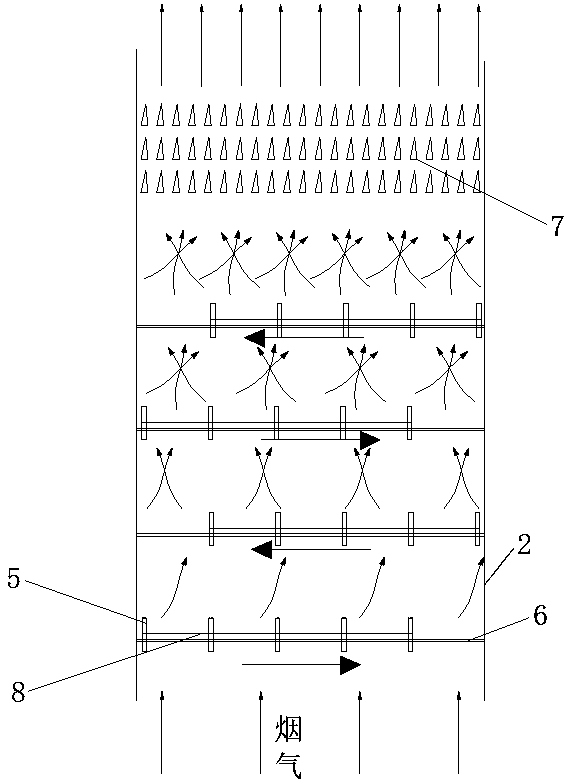

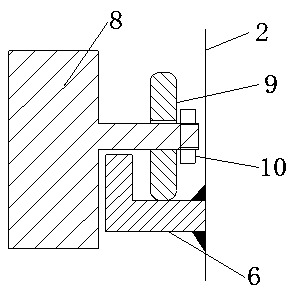

[0027] see Figure 1 to Figure 3 , in this embodiment, a reciprocating stirring type SCR reactor flue gas equalization device, including a motor 3, a reciprocating mechanism 4, a spoiler 5, a guide groove 6, a rectifier 7, a beam 8, a guide pulley 9 and fixing bolts 10. The motor 3 is arranged outside the inlet flue 2 of the SCR reactor 1. The rotating shaft of the motor 3 extends into the inlet flue 2 and is connected with the reciprocating mechanism 4. The reciprocating mechanism 4 is connected with the beam 8, and the beam 8 passes through the guide The groove 6 is connected to both sides inside the inlet flue 2, and there are several groups of crossbeams 8 arranged from bottom to top, each gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com