Nano-silver conductive ink and low-temperature sintering method thereof

A conductive ink, low-temperature sintering technology, applied in ink, household utensils, applications, etc., can solve the problems of ink sintering temperature rise, high resistance, poor conductivity, etc., and achieve the effect of excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

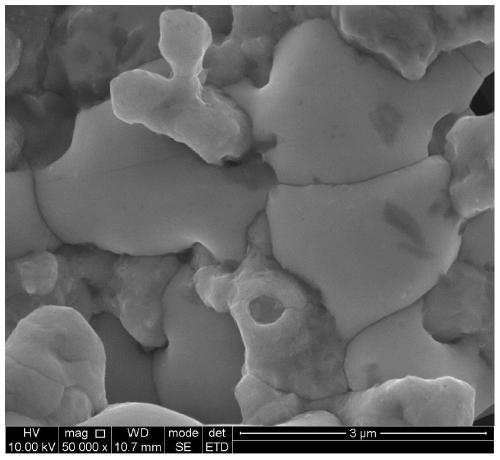

Embodiment 1

[0034] Add 4.3g of potassium citrate and 8g of glucose into 50 mL of deionized water in turn, magnetically stir at 800 rpm for 20 min at room temperature, then add 6g of polyacrylic acid to it to obtain mixed solution A; dissolve silver nitrate in deionized water A solution B with a concentration of 10 mol / L was obtained. Add 10 mL of solution B dropwise to solution A at a rate of 30 drops / min, stir magnetically for 20 min, and then react in a water bath at 60°C for 60 min, maintaining a magnetic stirring rate of 800 rpm. Then cool naturally at room temperature and keep magnetic stirring. After the product is allowed to stand, the supernatant is discarded to obtain silver nanoparticles.

[0035] After utilizing the polyaluminum chloride aqueous solution of 3mol / L to dissolve nano-silver particle, add the dehydrated alcohol of three times of deionized water volume wherein, 8000rpm centrifugal 10 minutes, repeat three times. Then the nano-silver particles were first dissolved ...

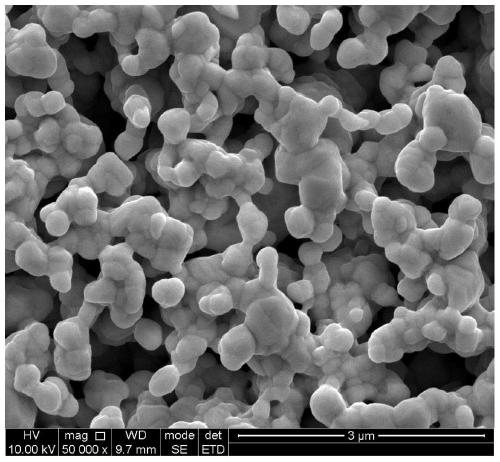

Embodiment 2

[0040] Add 4.3g of potassium citrate and 8g of glucose into 50mL of deionized water in turn, magnetically stir at a speed of 800rpm at room temperature for 20min, then add 6g of polyacrylic acid to it to obtain mixed solution A; dissolve silver nitrate in deionized water to obtain a concentration of 10mol / L solution B. Add 10 mL of solution B dropwise to solution A at a rate of 30 drops / min, stir magnetically for 20 min, and then react in a water bath at 60°C for 60 min, maintaining a magnetic stirring rate of 800 rpm. Then cool naturally at room temperature and keep magnetic stirring. After the product is allowed to stand, the supernatant is discarded to obtain silver nanoparticles.

[0041]After utilizing the polyaluminum chloride aqueous solution of 1mol / L to dissolve nano-silver particle, add the dehydrated alcohol three times of deionized water volume wherein, 8000rpm centrifuges 10 minutes, repeats three times. Then the nano-silver particles were first dissolved in dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com