Cotton cloth production process and cotton cloth structure thereof

A production process and cotton cloth technology, applied in the field of fabric production technology, can solve the problems of wetting the inner layer of clothes, low air permeability, insufficient warmth retention, etc., and achieve the effects of increasing the thickness of the fabric, having a good thermal insulation effect, and improving the thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

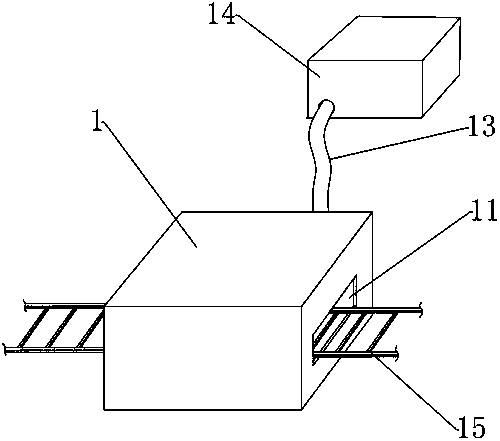

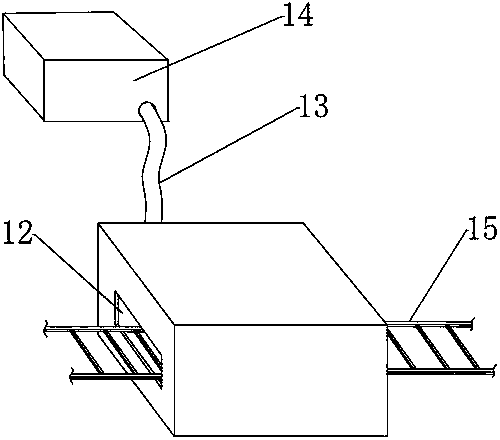

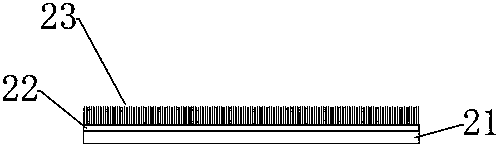

[0034] A production process of cotton cloth is characterized in that it is completed in the following steps:

[0035] A. Disperse the cotton to form uniform cotton filaments;

[0036] B. Install the whole roll of fabric on the unwinder of the production line and fix it;

[0037] C. Transport the fixed roll of cloth to the cleaning machine for surface cleaning;

[0038] D. Convey the cleaned cloth to the vacuum machine for surface vacuum treatment;

[0039] E. Transport the dust-absorbed cloth to the glue sprayer for surface spraying with glue;

[0040] F. Transport the cloth sprayed with glue to the cotton spraying machine to spray cotton on the surface, so that the cotton sticks tightly on the surface of the glue;

[0041] G. Convey the fabric that has been glued with cotton silk to the air-conditioning box, and cool the glue quickly through freezing to make the cotton silk stick tightly;

[0042] H. Transport the cooled fabric to the suction machine, and loosen the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com