Steel mesh hollow component with supporting points

A technology for stenciling and supporting points, which is applied in the processing of building components, building structures, and building materials, etc., can solve problems such as affecting the normal use of construction equipment, changing the strength of concrete structures, and blocking the pipelines of cast-in-place concrete delivery pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

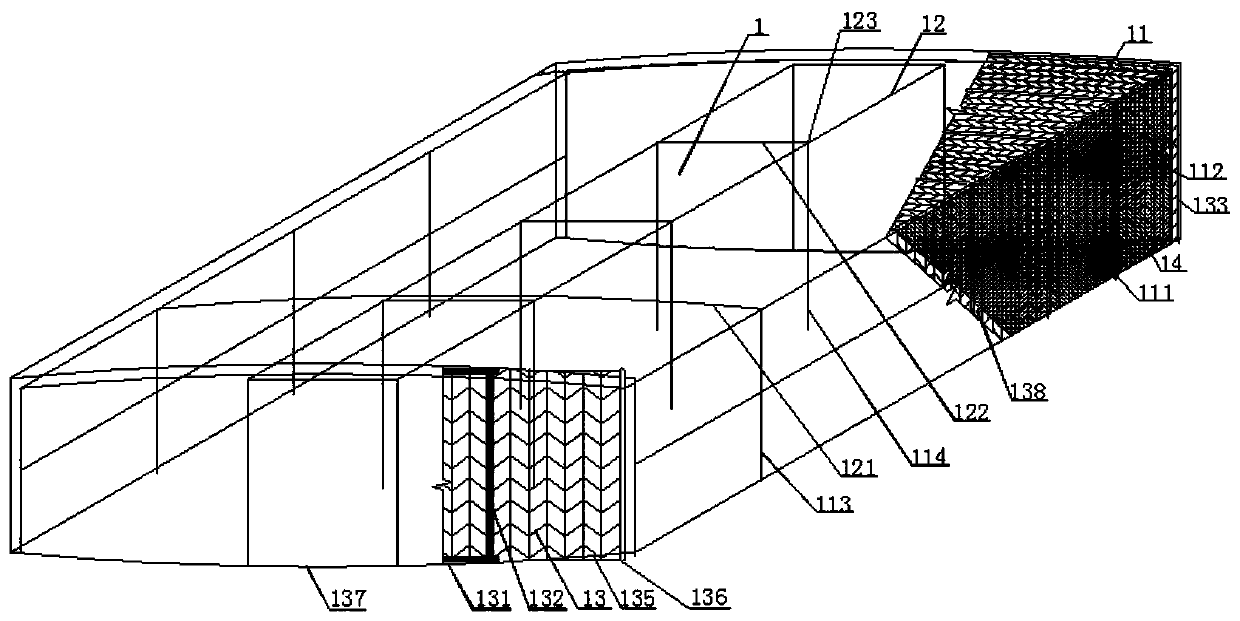

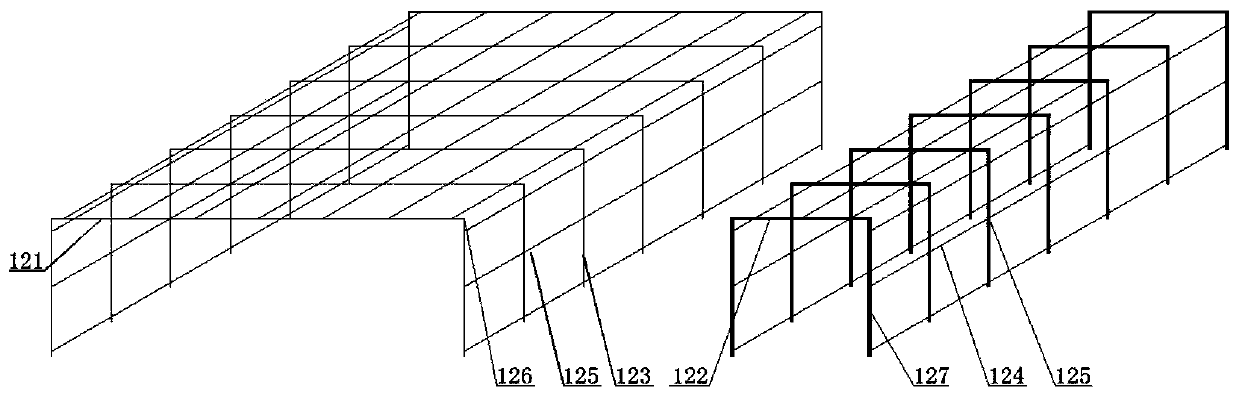

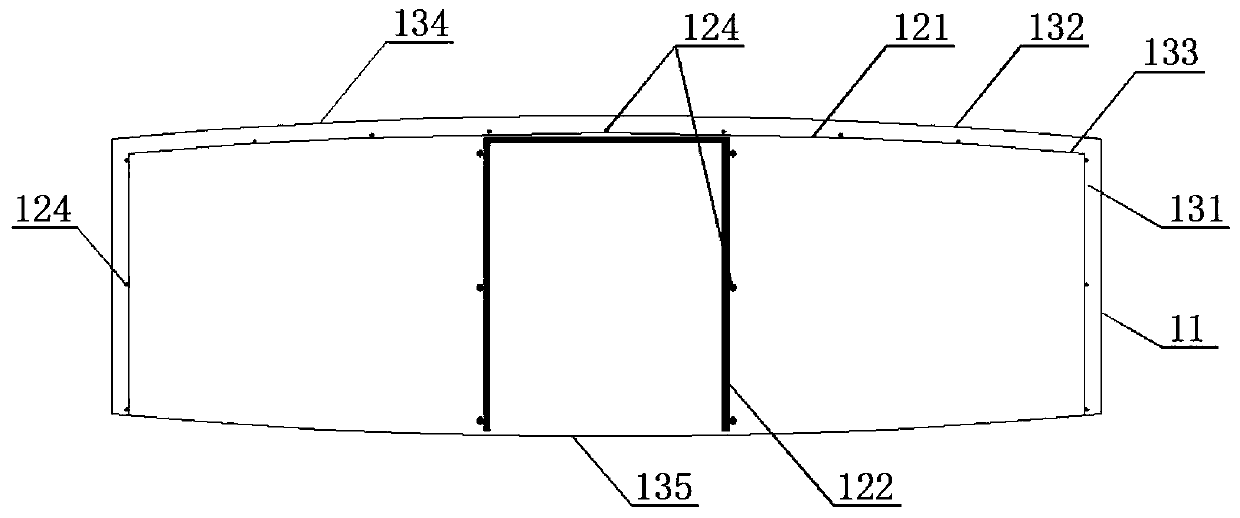

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] figure 1It is an embodiment of a stenciled member with supporting points of the present invention. When the present invention is implemented, according to the requirements of the function of the stenciled member 1, the ribbed steel mesh 11, the composite laminated support frame 12, and the short plug are first made. The web 13 and the non-woven fabric 14 are reeled; the ribs of the ribbed steel mesh 11 with ribs 111 and connecting pieces 112 are horizontally pressed with two cuts to control the width according to the required specifications to control the width and the height with two cuts 50mm of overlap is reserved at both ends of the ribbed steel mesh; the composite laminated support frame is divided into wide groups 121 to form width 113 and narrow groups 122 to form height 114; Wire-drawing equipment, cold-drawing the coiled steel wire into a cold-drawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com