High-temperature helium level sealing isolation valve for nuclear power station

A technology for nuclear power plants and isolation valves, used in shaft seals, lift valves, valve details, etc., to solve problems such as difficulty in achieving helium-level sealing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

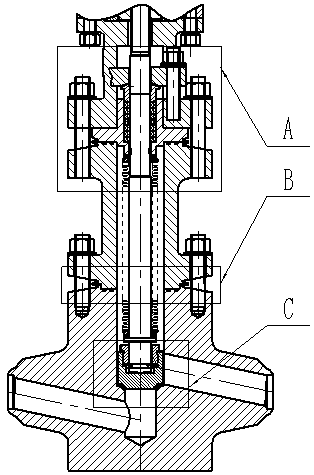

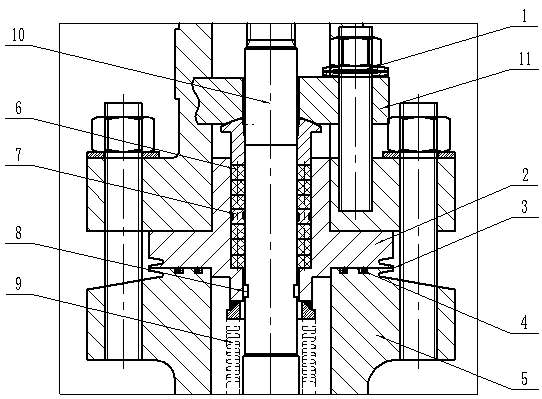

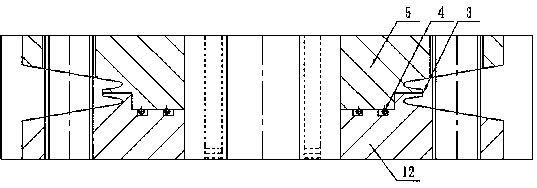

[0015] As shown in the figure, a high-temperature helium-level sealed isolation valve for nuclear power plants includes a valve body 12, a valve cover 5, a valve stem 10, a stuffing box 2, a packing pressure plate 11, a valve disc 13, a valve cover 5 and a stuffing box 2, The abutment surface of the valve body 12 is provided with a metal O-ring 4 to realize the primary seal of the static seal between the valve body 12 and the valve cover 5. The main material of the metal O-ring 4 is 1Cr18Ni9Ti, the outer surface is plated with silver, and the thickness is 30-40 μm , used to metal compensate the surface defects of the O-ring 4 pipe and enhance the corrosion resistance and sealing performance. There is a lip sealing weld 3 at the connection between the valve cover 5 and the stuffing box 2 and the valve body 12. When the sealing performance of the metal O-ring 4 In the event of failure, the lip can be welded to provide a secondary seal. The bellows is connected to the valve stem,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com