Temperature measurement sampling robot process arrangement and operation process for steelmaking production refining treatment

A robot and sampler technology, applied in the field of metallurgy, can solve problems such as the inability to achieve one-button intelligent automatic steelmaking, improve the success rate and data reliability, stabilize the determination of molten steel composition and temperature, and improve alloy yield. yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

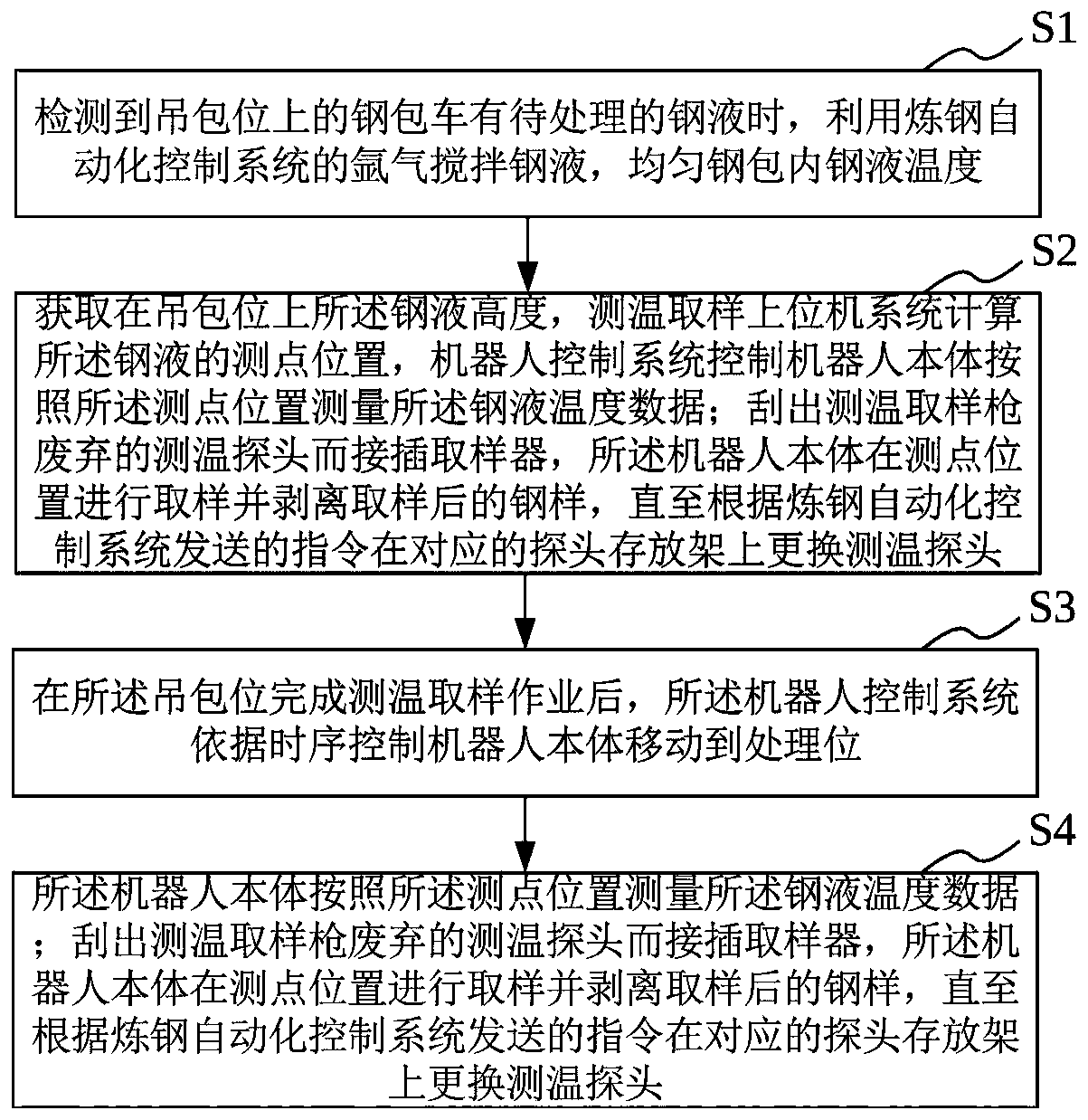

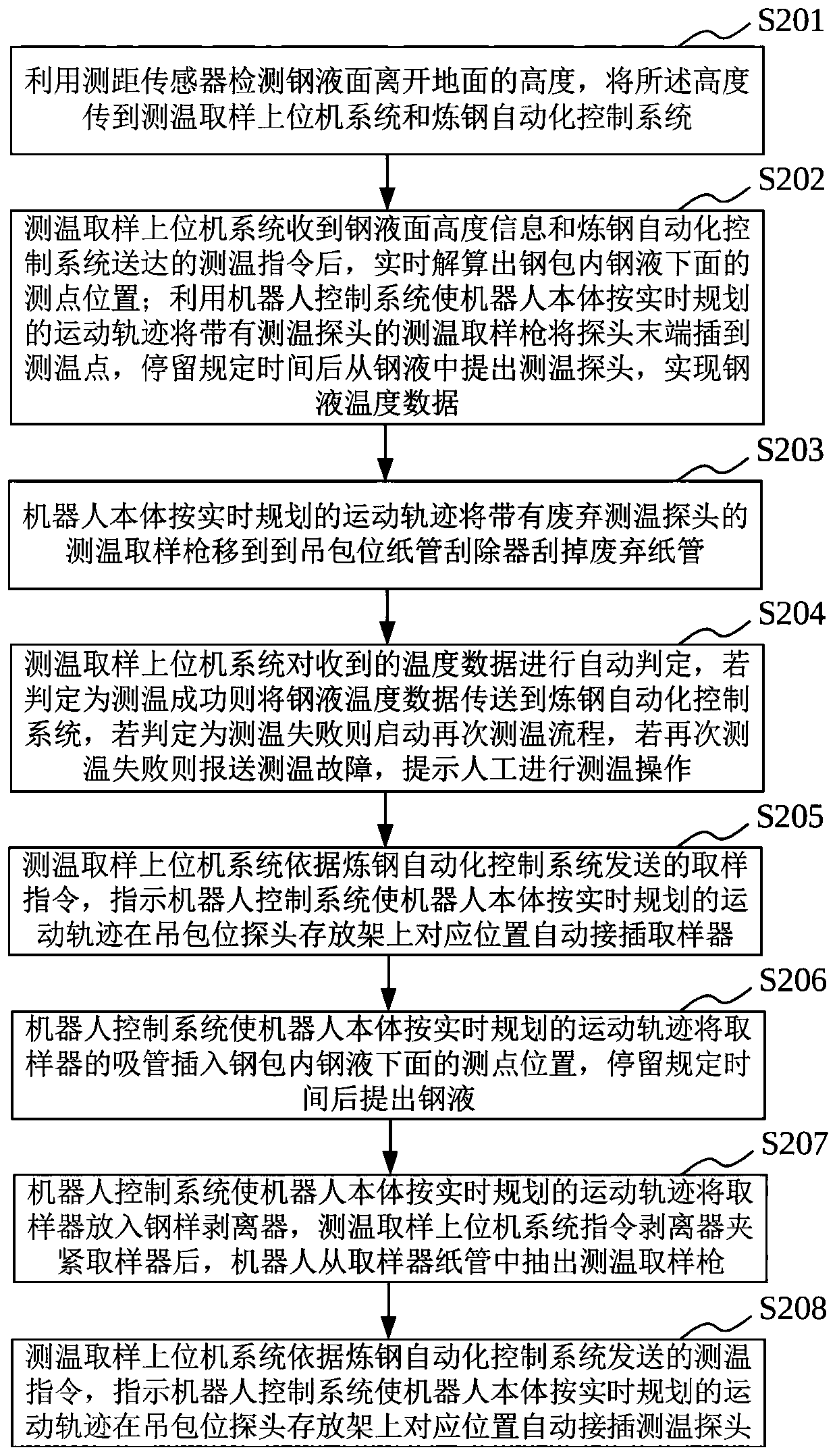

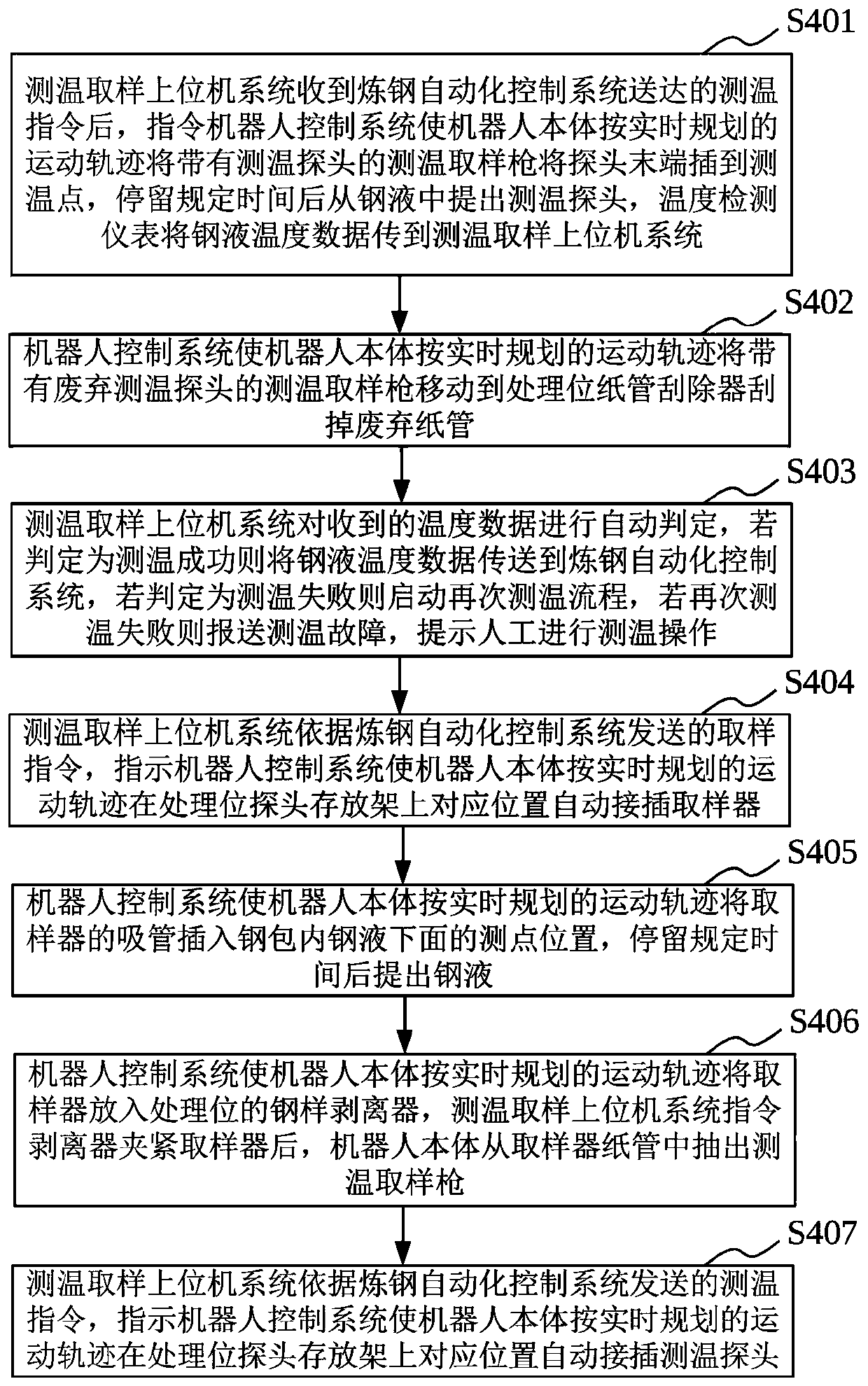

Method used

Image

Examples

Embodiment 1

[0060] Take the metallurgical production of a 150tLF furnace in a steelmaking plant as an example. The LF furnace (ladle refining furnace) is arranged with collinear double ladle cars and single processing station (see details Figure 4 to Figure 6 ), while one ladle car is at the processing position for refining treatment, the other ladle car can be at the wire feeding position or ladle lifting position, so that the refining process time of the two ladles overlaps, thereby shortening the interval between ladle refining, Shorten the production cycle. In order to avoid the obvious hazards caused by the splashing of molten steel to the manual temperature measurement and sampling operation, from the perspective of safety and intelligent improvement, a new robot is added to replace the manual temperature measurement and sampling operation. The temperature measurement and sampling operation process is as follows:

[0061] 1) Ladle entering the station: the metallurgical crane lif...

Embodiment 2

[0088] Take the metallurgical production of 60tLF furnace in a steelmaking plant as an example. The LF furnace adopts double processing positions with rotating electrode arms and a double row ladle car arrangement (see Figure 5 and Figure 7 ), while one ladle car is at the processing position for refining treatment, the other ladle car can be at the wire feeding position or ladle lifting position, so that the refining process time of the two ladles overlaps, thereby shortening the interval between ladle refining and shortening Production cycle. In order to avoid the obvious hazards caused by the splashing of molten steel to the manual temperature measurement and sampling operation, from the perspective of safety and intelligent improvement, a new robot is added to replace the manual temperature measurement and sampling operation. The process layout of the temperature measurement and sampling robot is as follows:

[0089] The refining treatment process design of double pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com