Cutter attitude optimization method for geometric error compensation of five-axis machine tool

A technology of geometric error and optimization method, applied in the direction of computer control, instrument, simulator, etc., can solve problems such as error, achieve the effect of realizing geometric error compensation, improving machining accuracy and workpiece surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

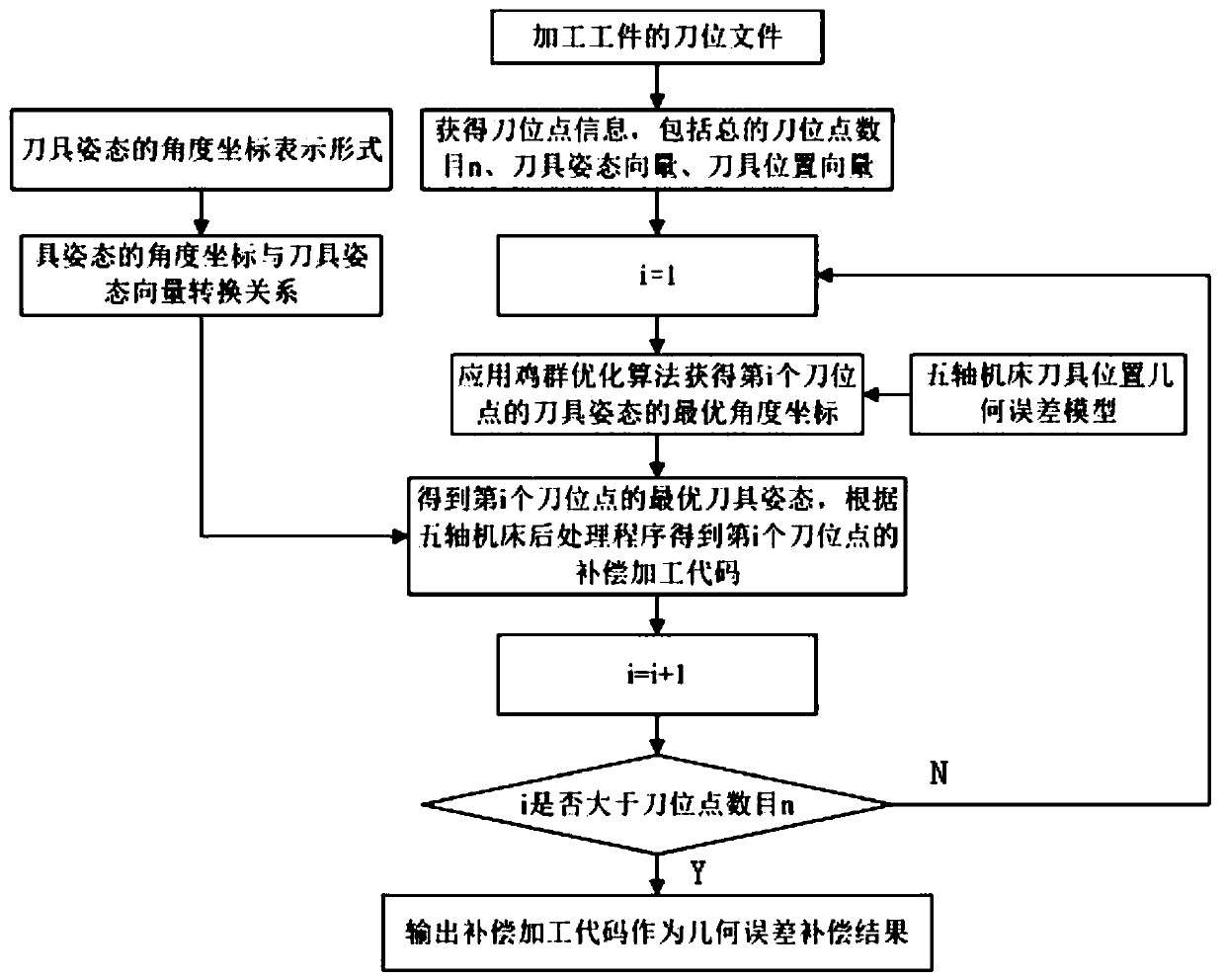

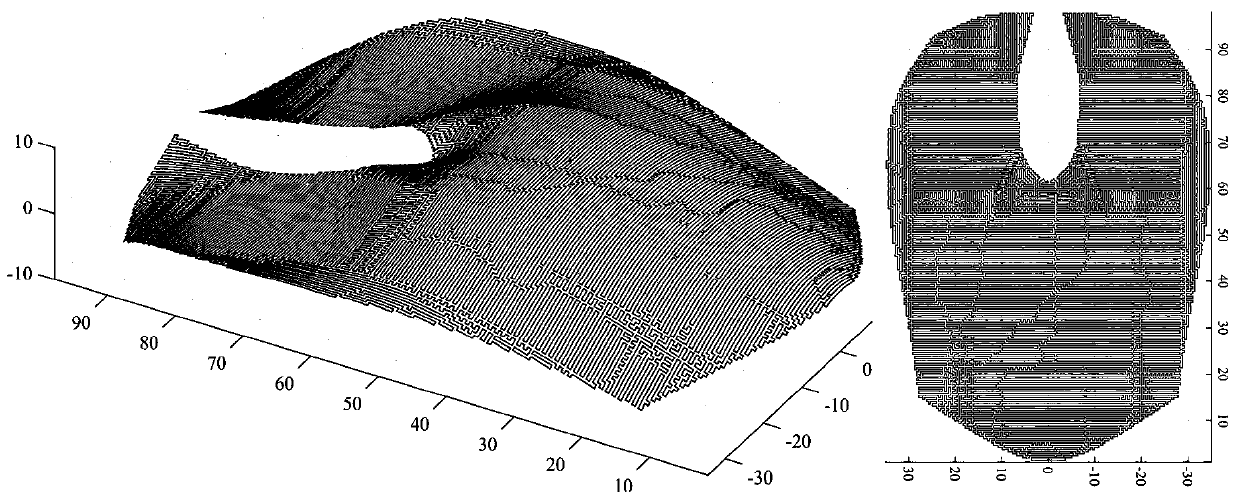

[0048] Such as figure 1 As shown, the present invention provides a tool attitude optimization method for geometric error compensation of a five-axis machine tool, which can effectively solve the problem of compensating geometric errors constrained by the texture of the workpiece from the tool touch trajectory representing the texture of the workpiece. In order to further improve the present invention to explain, such as figure 2 as shown, figure 2 It is a mouse-shaped workpiece and the machining tool path. Taking the SmartCNC500_DRTD five-axis CNC machine tool to process this workpiece as an example, the tool posture optimization method for geometric error compensation of the five-axis machine tool is explained. The implementation method is as follows:

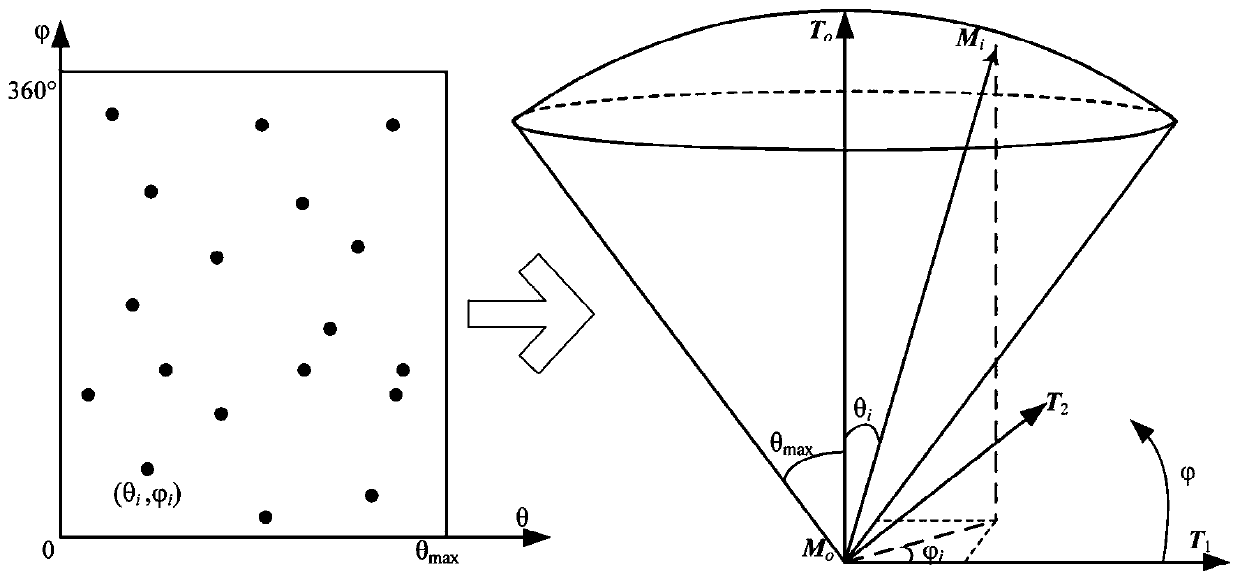

[0049] S1. Construct the angular coordinate representation of tool attitude where θ represents the tilt angle relative to the reference tool attitude vector, Indicates the rotation angle relative to the reference tool a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com