Multilayer micro-perforated plate sound absorption structure

A micro-perforated plate and sound-absorbing technology, applied in sound-generating equipment, layered products, instruments, etc., can solve the problems of general sound absorption performance and complex structure in the whole frequency band, and achieve good low-frequency sound insulation performance, high sound absorption coefficient, The effect of improving the sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The directions of the accompanying drawings are up, down, left and right.

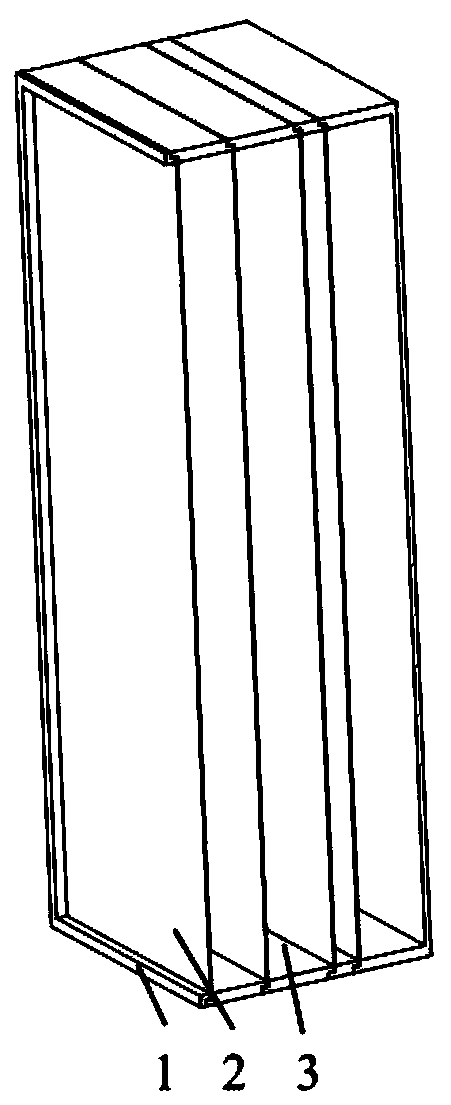

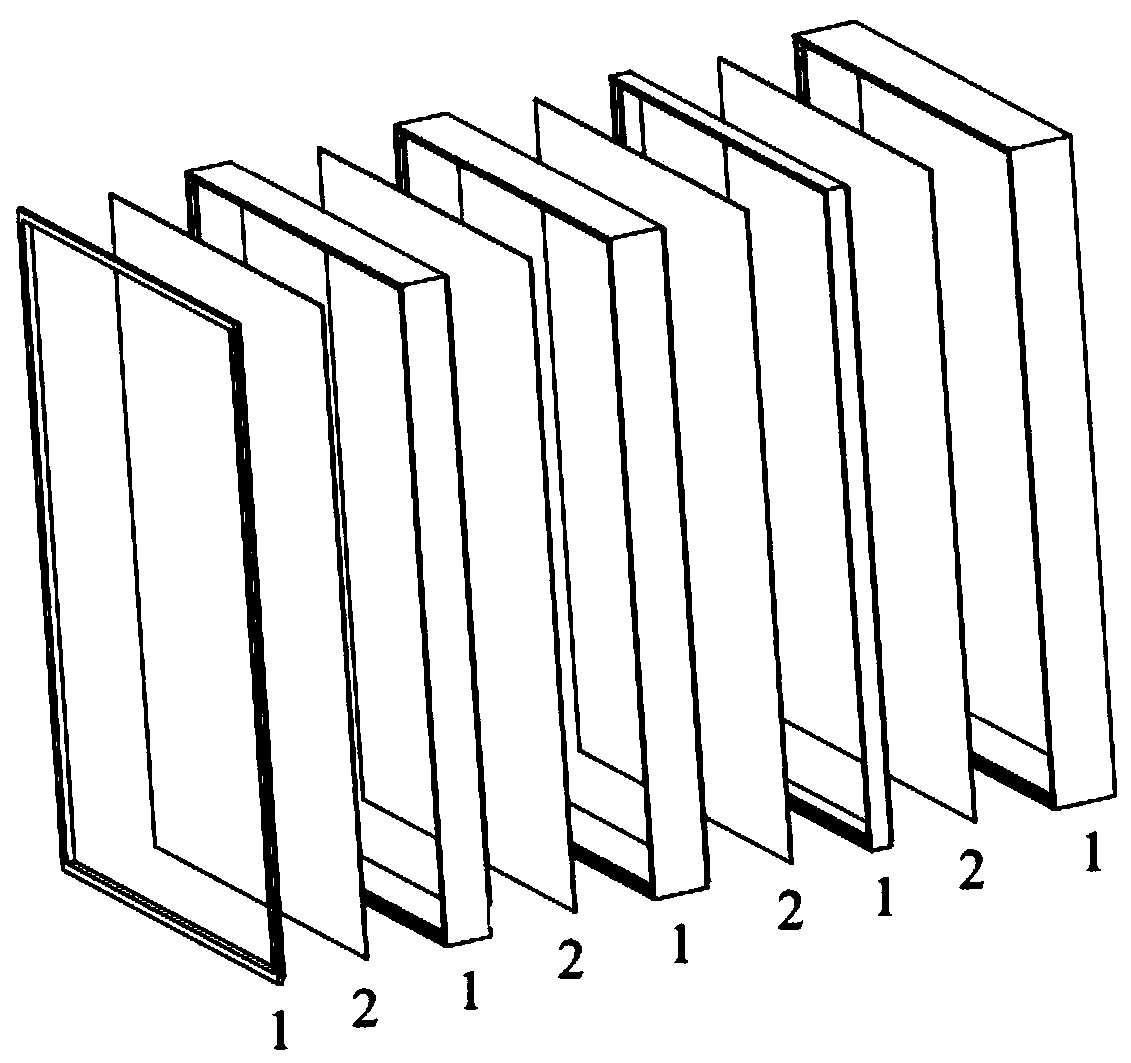

[0023] Such as figure 1 The multi-layer micro-perforated plate sound-absorbing structure includes five frames 1 and four micro-perforated plates 2 arranged in series at intervals, and four sound-absorbing cavities 3 enclosed thereby.

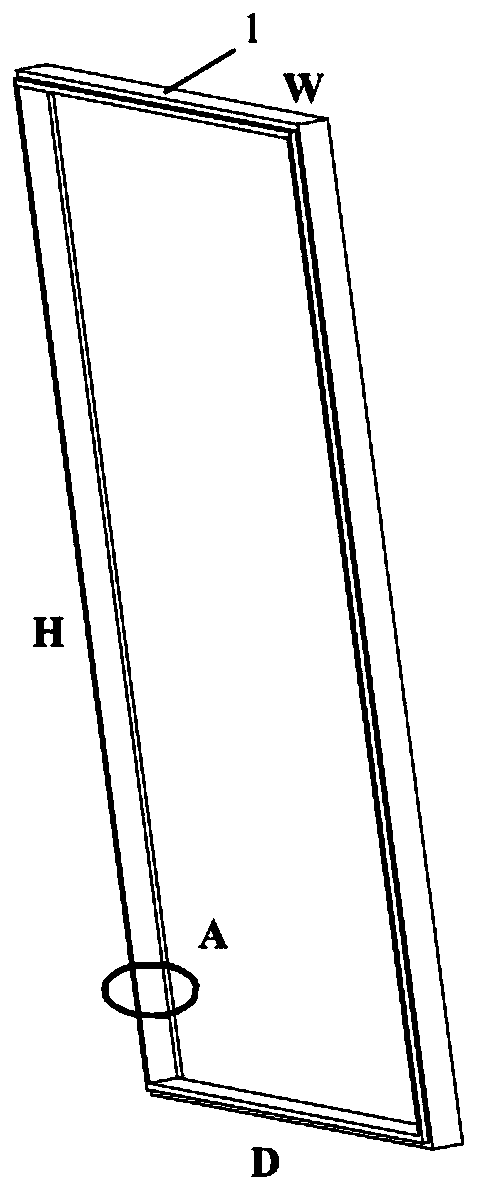

[0024] Such as figure 2 , the outer dimension of the first frame body 1 from left to right is 4mm(W)×200mm(D)×300mm(H), and the inner dimension is 4mm(W’)×192mm(D’)×292mm(H’) , which is connected with the second frame body 1 to fix the first micro-perforated plate 2 . The outer dimension of the second frame body 1 is 23.5mm (W) × 200mm (D) × 300mm (H), the inner dimension is 23.5mm (W') × 192mm (D') × 292mm (H'), one end is connected with The first frame body 1 is connected to support the first micro-perforated plate 2, determine its position in the second frame body 1, and form the required sound-absorbing cavity 3 (D c =21mm); the other end is connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com