Baisi glutinous rice cake easy to digest

A technology for white silk glutinous rice cake and glutinous rice cake, which is applied in the field of white silk glutinous rice cake, can solve the problems of stickiness, food accumulation, abdominal pain and even diarrhea, incomplete digestion and other problems, and achieves the effect of being conducive to digestion, delicate taste and gastrointestinal friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

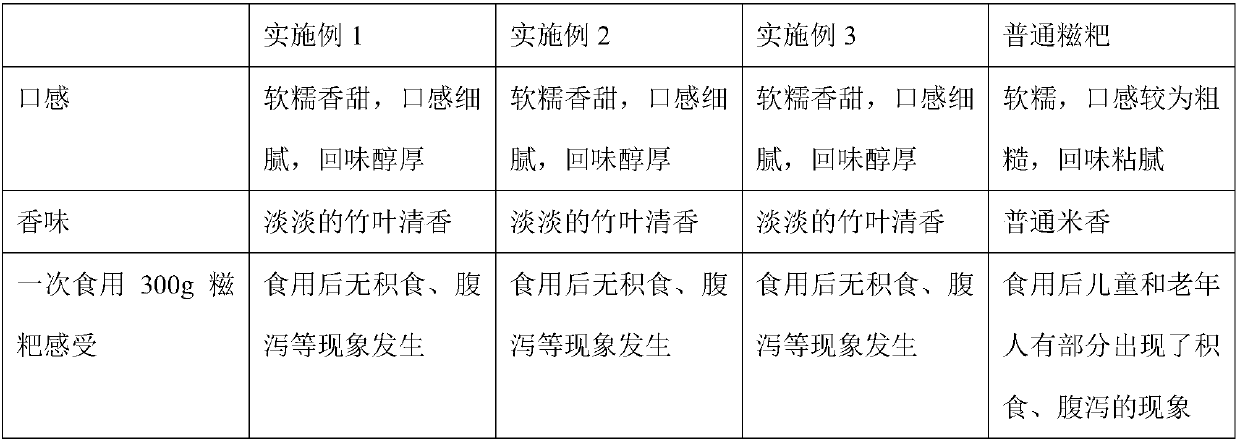

Examples

Embodiment 1

[0016] Raw materials for making glutinous rice cakes: 4000g glutinous rice, 1500g cassava flour, 800g yam, 80g white sesame powder, 500g water, and 100g functional powder that promotes digestion and absorption. Powder, licorice powder, and coriander shell powder are ultra -micro crushed powder. Glutinous rice is white silk glutinous rice produced in Xipu County, Huaihua City.

[0017] Its preparation method is as follows:

[0018] 1) Soak glutinous rice: Remove impurities from the glutinous rice, weigh it, place it in a wooden barrel, soak it in water at 10°C for 24 hours, remove it, and drain it for later use;

[0019] 2) Steam glutinous rice: Choose fresh bamboo leaves, scrub and drain the fresh bamboo leaves for later use, lay a layer of fresh bamboo leaves and a layer of glutinous rice in the steamer, and lay the peeled yam on the fresh bamboo leaves in the middle layer After the laying is completed, steam it on high heat; the steamer uses a conical wooden steamer with a ...

Embodiment 2

[0022] Prepare raw materials for making glutinous rice cakes: 3000g glutinous rice, 1000g cassava flour, 600g yam, 50g white sesame powder, 400g water, and 80g functional powder that promotes digestion and absorption. Powder, licorice powder, and coriander shell powder are ultra -micro crushed powder. Glutinous rice is white silk glutinous rice produced in Xipu County, Huaihua City.

[0023] Its preparation method is as follows:

[0024] 1) Soak glutinous rice: Remove impurities from the glutinous rice, weigh it, put it in a wooden barrel, soak it in water at 0°C for 28 hours, remove it, and drain it for later use;

[0025] 2) Steam glutinous rice: Choose fresh bamboo leaves, scrub and drain the fresh bamboo leaves for later use, lay a layer of fresh bamboo leaves and a layer of glutinous rice in the steamer, and lay the peeled yam on the fresh bamboo leaves in the middle layer After the laying is completed, steam it on high heat; the steamer uses a conical wooden steamer wit...

Embodiment 3

[0028] Raw materials for making glutinous rice cakes: 3800g glutinous rice, 1200g cassava flour, 650g yam, 60g white sesame powder, 500g water, and 120g functional powder that promotes digestion and absorption. , licorice powder and Citrus aurantium powder are all superfine powders, and the glutinous rice is white silk glutinous rice produced in Xupu County, Huaihua City.

[0029] Its preparation method is as follows:

[0030] 1) Soak glutinous rice: Remove impurities from the glutinous rice, weigh it, put it in a wooden barrel, soak it in water at 0°C for 28 hours, remove it, and drain it for later use;

[0031] 2) Steam glutinous rice: Choose fresh bamboo leaves, scrub and drain the fresh bamboo leaves for later use, lay a layer of fresh bamboo leaves and a layer of glutinous rice in the steamer, and lay the peeled yam on the fresh bamboo leaves in the middle layer After the laying is completed, steam it on high heat; the steamer uses a conical wooden steamer with a radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com