A device and method for casting heterogeneous metal rods

A metal bar and metal technology, applied in the field of heterogeneous material preparation, can solve the problems of inability to flexibly adjust the microstructure, inability to prepare large-size samples, and complex rolling process procedures, etc., to achieve flexibility, directionality, and low price , High yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

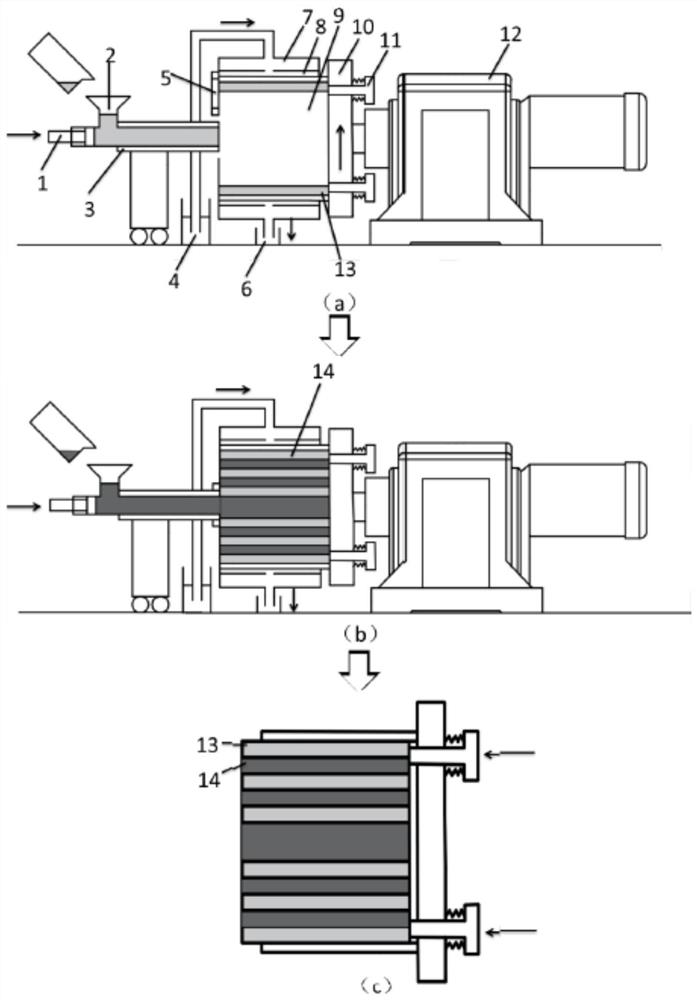

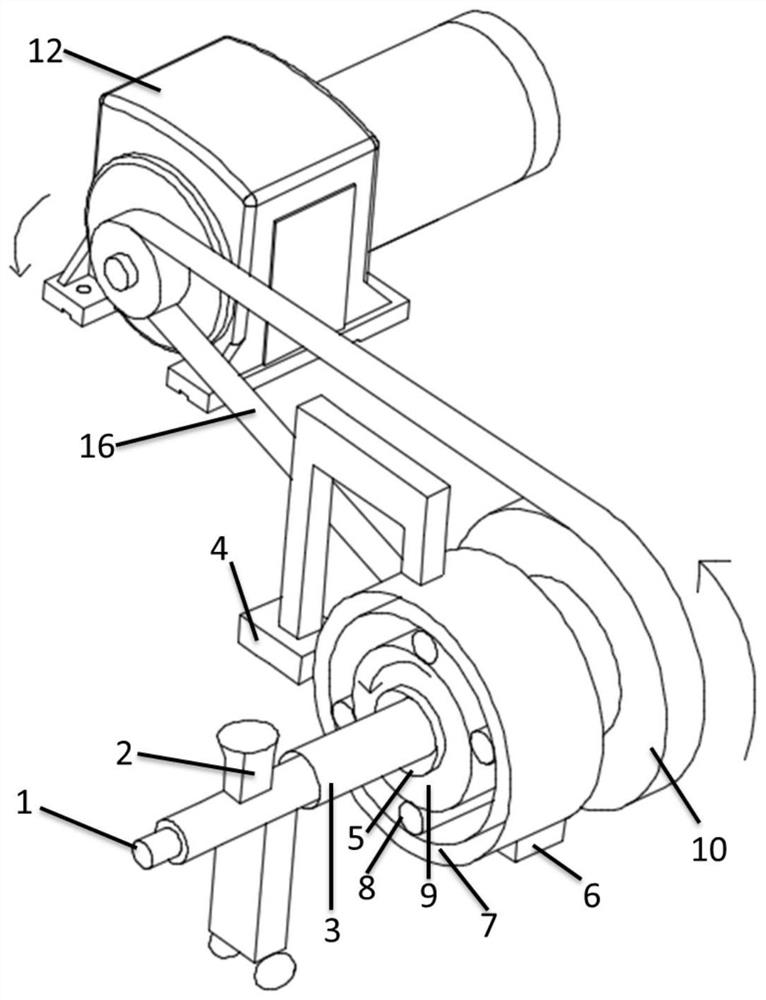

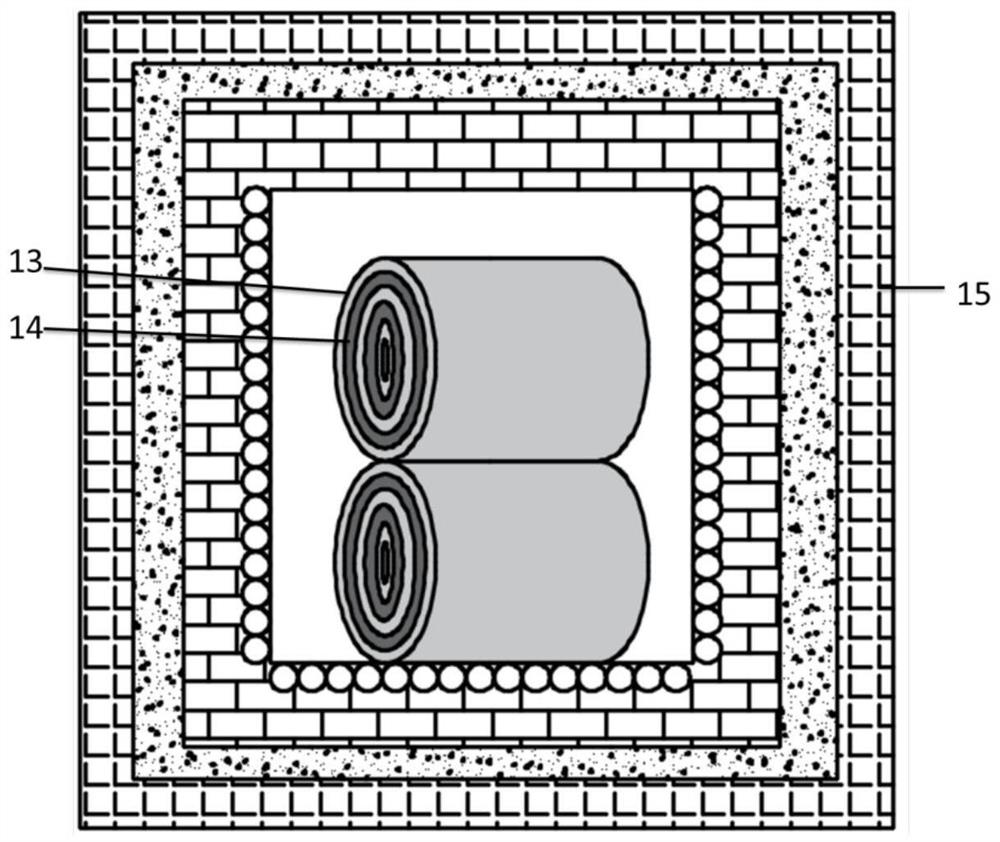

[0047] like Figure 1-4 As shown, the heterogeneous copper alloy rod composed of brass and pure copper is used as Example 1, and the detailed implementation and specific operation are given. The following examples involve four processes: centrifugal casting, pressure casting, demolding, and stress relief annealing ,in:

[0048] The first step is centrifugal casting. like figure 2 As shown in middle (a), open the cover plate 5, start the motor, dock the feeding car with the casting mold 9, inject the brass molten metal into the feeding port 2, and push the piston 1 at the same time so that the molten metal quickly enters the casting mold for centrifugation For casting, the rotating speed of the casting mold is 600r / min. After the first casting is completed, keep warm for 5 minutes, pour pure copper molten metal, repeat the above steps until the inner diameter of the cast pipe is close to the outer diameter of the sprue opening, and obtain a tubular material in which brass a...

Embodiment 2

[0053] Taking the heterogeneous aluminum alloy rod composed of 7075 aluminum alloy and pure aluminum as Example 2, the detailed implementation and specific operation are given. The following example involves four processes: centrifugal casting, pressure casting, demoulding, and stress relief annealing. :

[0054] The first step is centrifugal casting. like figure 2 As shown in middle (a), open the cover plate 5, start the motor, dock the feeding car with the casting mold 9, inject 7075 aluminum alloy metal liquid into the feeding port 2, and push the piston 1 at the same time so that the metal liquid quickly enters the casting mold. For centrifugal casting, the rotational speed of the casting mold is 600r / min. After the first casting is completed, keep warm for 5 minutes, pour pure aluminum molten metal, repeat the above steps until the inner diameter of the cast pipe is close to the outer diameter of the sprue gate, and obtain a tubular material in which 7075 aluminum allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com