Electron beam welding universal platform

An electron beam welding, universal platform technology, applied in electron beam welding equipment, welding equipment, welding equipment and other directions, can solve the problems of limiting size and shape, affecting positioning and pressing, etc., to maximize rigidity, improve efficiency, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

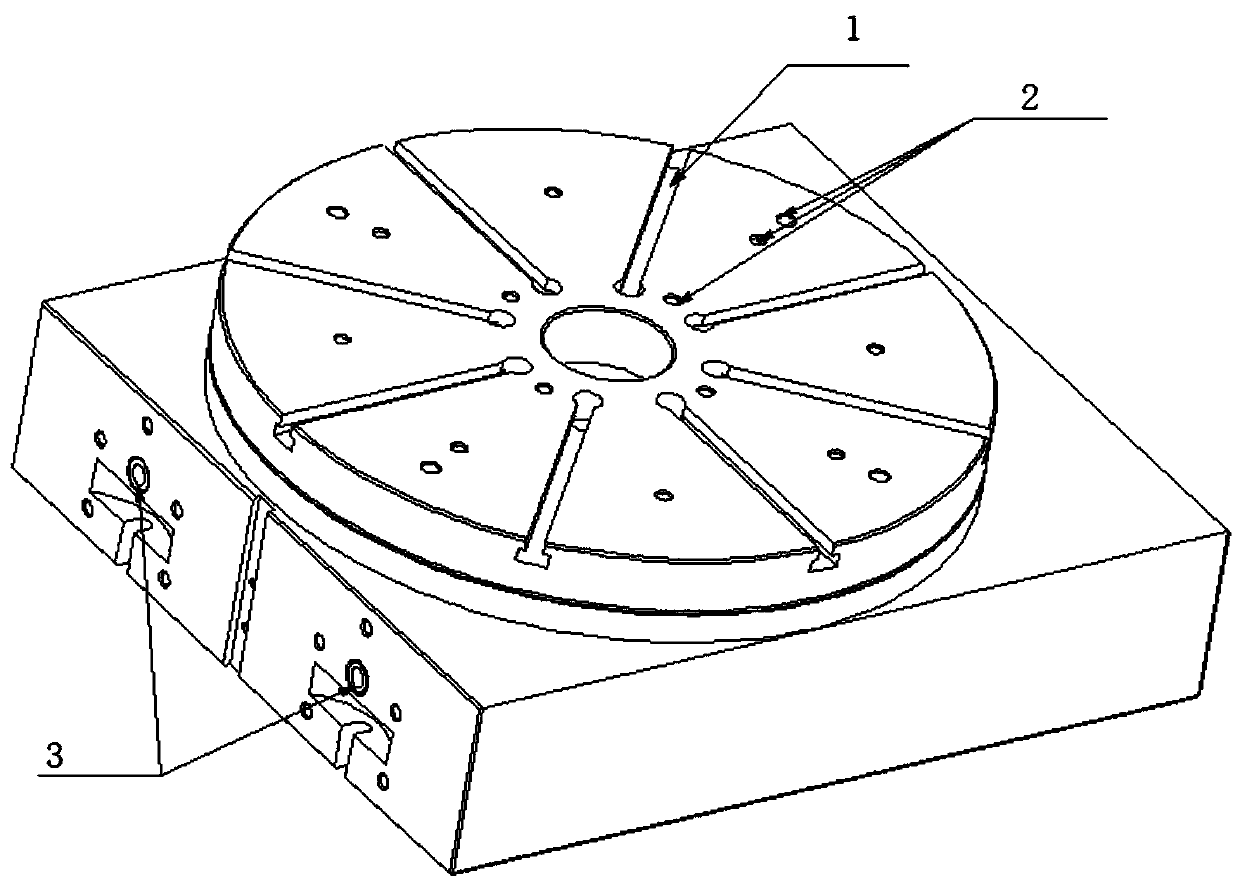

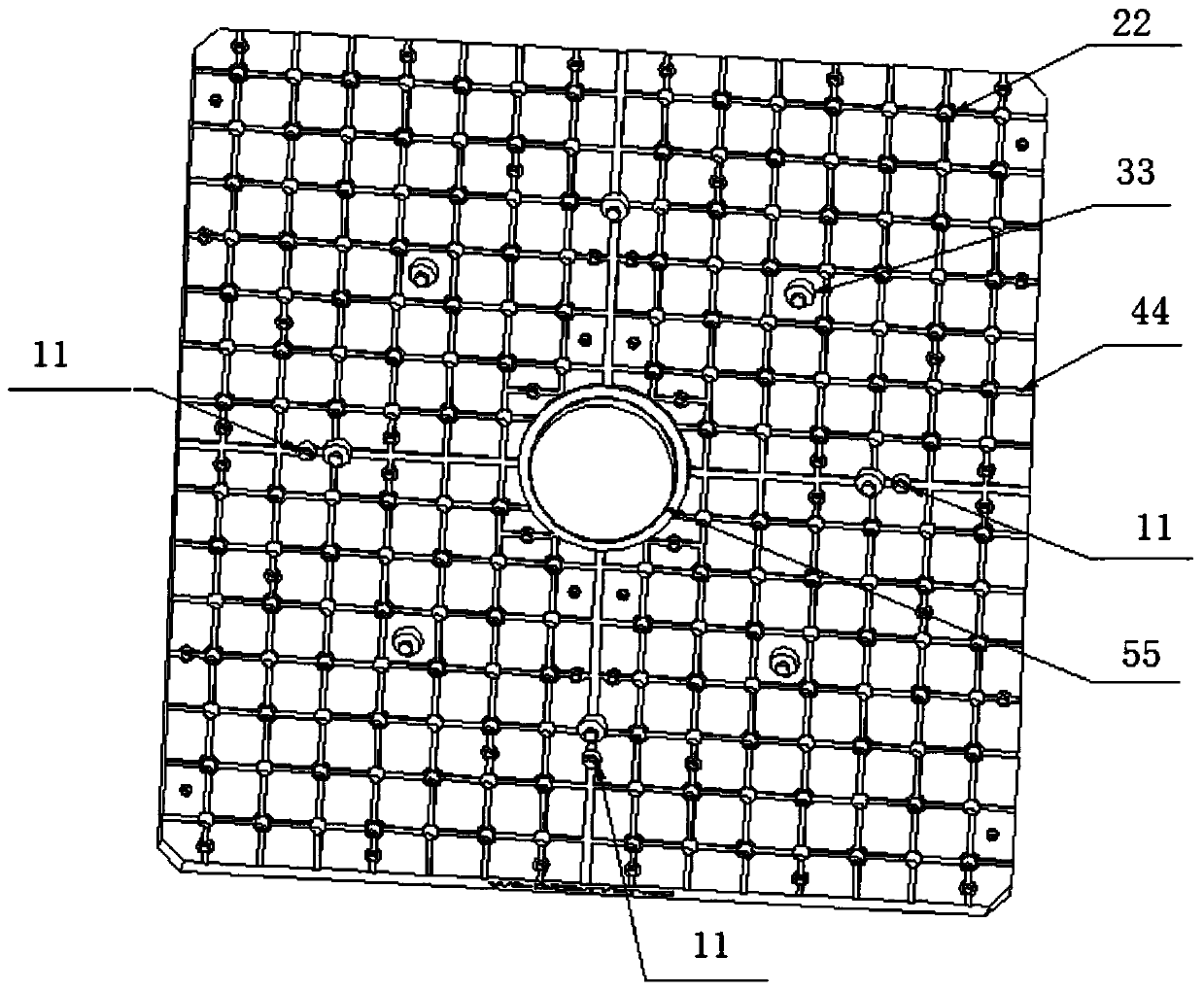

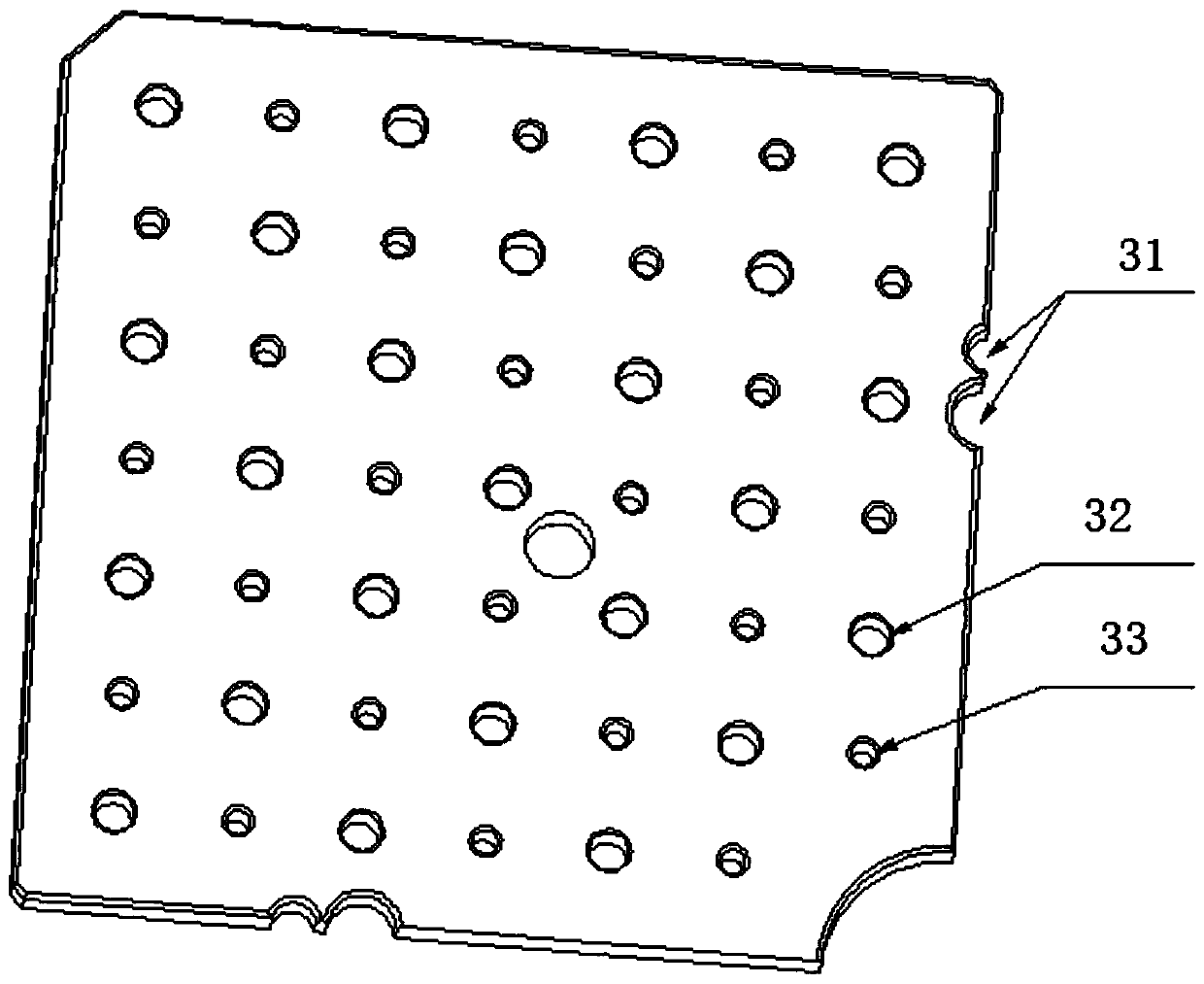

[0023] combined with Figure 1-10 and reference numerals describe the present invention in detail.

[0024] A general platform for electron beam welding, comprising a positioner 1, an aluminum plate base 2 is arranged on the positioner 1, the aluminum plate base 2 is provided with a stainless steel plate 3 through a cylindrical pin 4 and a stepped pin 5, and the stainless steel plate is fixed by a stepped bush 6 3 Press onto the aluminum plate base 2.

[0025] The overall material of the positioner 1 is stainless steel, and the structural shape is a cylinder above a cuboid, with a T-shaped slot 11, a threaded hole 12 and a positioning hole 13, and the maximum load-bearing capacity can reach 1t.

[0026] The aluminum plate base 2 is made of aluminum (A6061), and its structural shape is a cube plate, with positioning precision holes 21, threaded holes 22, countersunk holes 23, exhaust grooves 24, center holes 25, and three cylindrical pins 4 and 8 A M12x30 stainless steel hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com