Heating mechanism of bottle preform with handle

A technology of first handle and preform, applied in the field of preform heating mechanism with handle, can solve the problems of complex mold structure, poor oxygen barrier performance, and many wastes, so as to ensure the quality of blowing and avoid softening and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

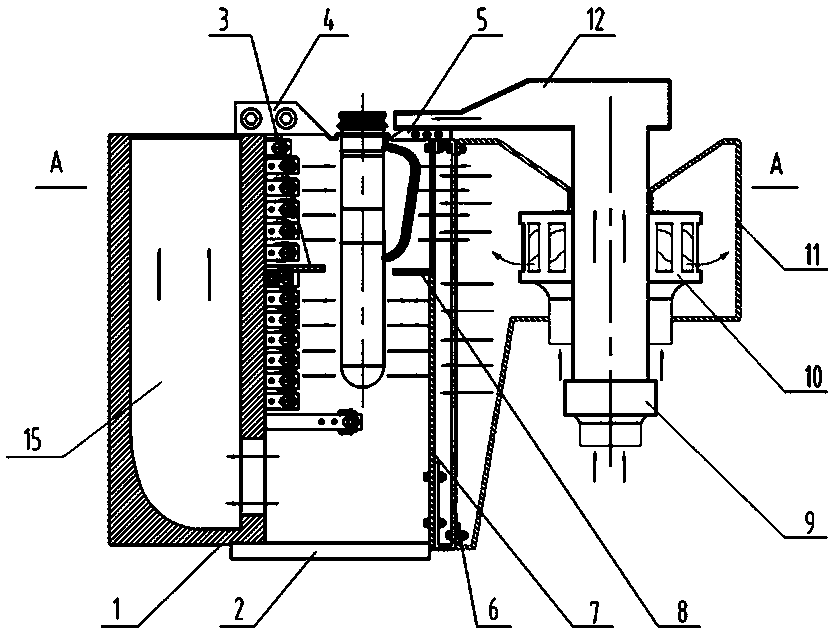

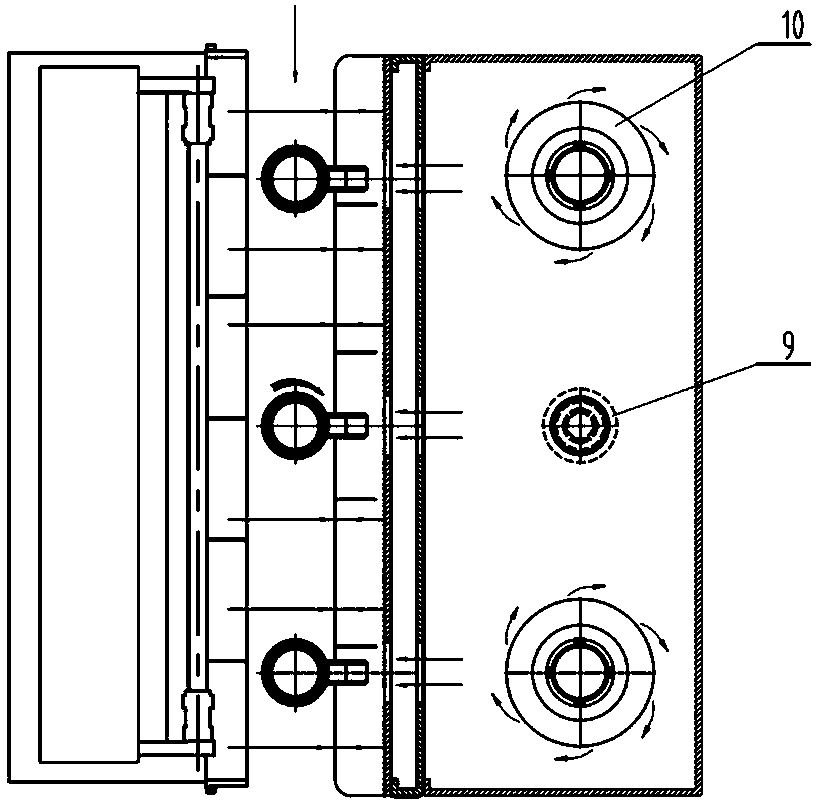

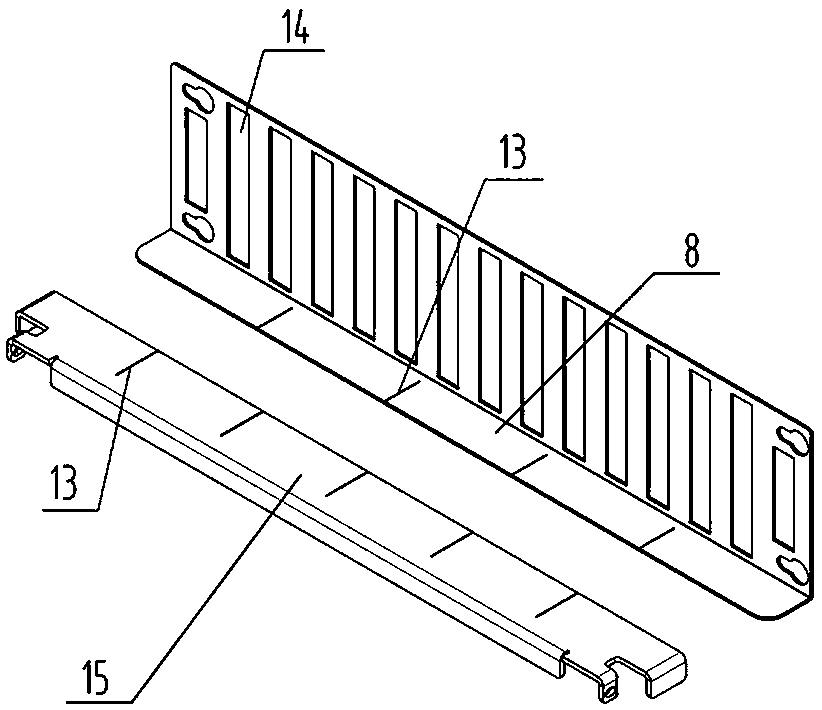

[0009] A preform heating mechanism with a handle, such as figure 1 with figure 2 As shown, it includes a heating box 1 provided with a heating lamp tube and a heat insulation board 2 arranged at the bottom of the heating box 1, and a reflector mounting frame 6 opposite to the heating box 1 is arranged on the heat insulation board 2. The top of the heating box 1 is provided with an outer cooling channel 4, and an inner cooling channel 5 is arranged at the top of the reflector mounting frame 6. There is a hole between the outer cooling channel 4 and the inner cooling channel 5 for the bottle mouth of the plastic preform to pass through. spacing, the heating box 1, heat insulation board 2, reflector mounting frame 6, outer cooling water channel 4 and inner cooling water channel 5 enclose a heating area for the bottle body of the plastic preform to be heated; The first handle protection plate 8 is arranged on the heating box 1, and the second handle protection plate 3 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com