Anti-fouling protective film for lacquer of rail traffic vehicle

A technology for rail transit vehicles and protective films, which is applied to biocide-containing paints, antifouling/underwater coatings, film/flaky adhesives, etc., and can solve the problem of paint surface damage, dirt and difficult cleaning, and cleaning work Inconvenience and other problems, to achieve the effect of long service life, low heat, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

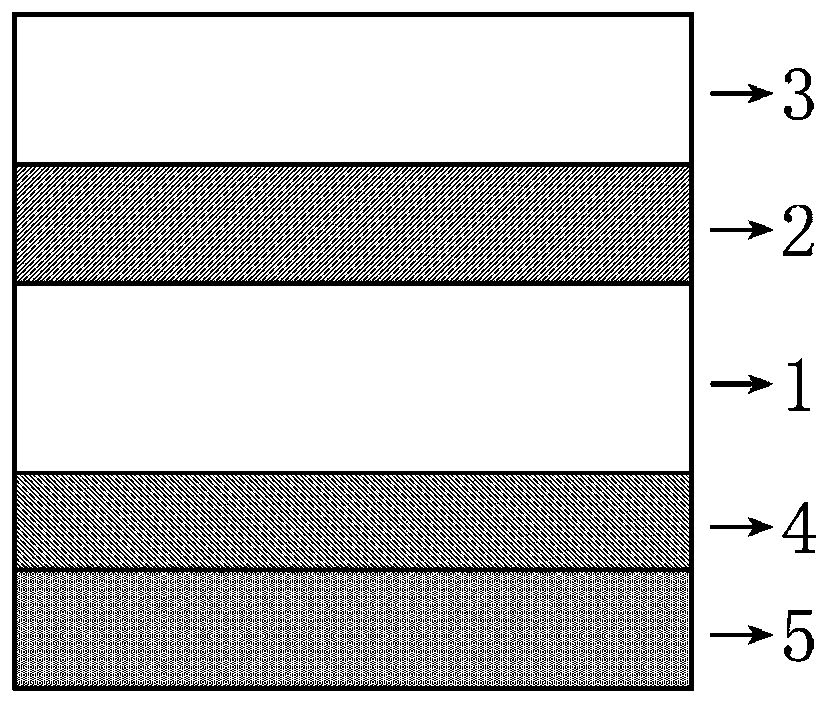

[0032] The stain-resistant protective film for rail cars comprises an adhesive adhesive layer, a base material layer and a stain-resistant layer arranged in sequence, wherein the process of setting the stain-resistant layer on the base material layer is: coating the stain-resistant layer on the base material layer , dried at 60-80°C for 1-2 minutes, and then cured in a UV LED light box with a curing light intensity of 800-1500mw / cm 2 , The curing time is 1-3 seconds. Among them, in order to facilitate the transportation of the produced protective film, a release film is provided on the other side of the adhesive layer, and a transparent protective film is compounded on the top of the stain-resistant layer to prevent damage. When the installation is in place, remove the release film and transparent protective film . Its structure is as figure 1 As shown in the figure, the base material layer 1; the stain-resistant layer 2; the transparent protective film 3; the pressure-sensi...

Embodiment 2

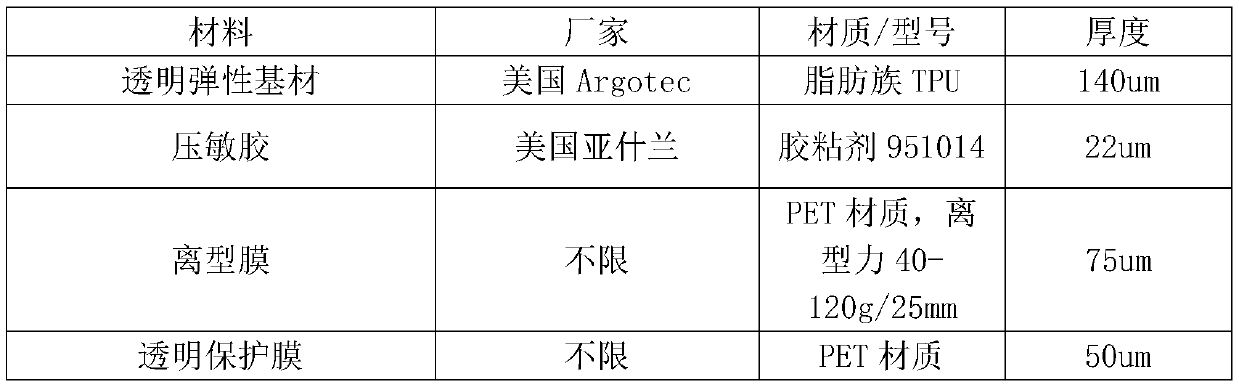

[0038] The stain-resistant protective film for rail cars comprises an adhesive adhesive layer, a base material layer and a stain-resistant layer arranged in sequence, wherein the process of setting the stain-resistant layer on the base material layer is: coating the stain-resistant layer on the base material layer , dried at 60-80°C for 1-2 minutes, and then cured in a UV LED light box with a curing light intensity of 800-1500mw / cm 2, The curing time is 1-3 seconds. Among them, in order to facilitate the transportation of the produced protective film, a release film is provided on the other side of the adhesive layer, and a transparent protective film is compounded on the top of the stain-resistant layer to prevent damage. When the installation is in place, remove the release film and transparent protective film . The material thickness of each layer of the protective film is shown in Tables 3 and 4 below.

[0039] table 3

[0040]

[0041]

[0042] Table 4

[0043] ...

Embodiment 3

[0045] The stain-resistant protective film for rail cars comprises an adhesive adhesive layer, a base material layer and a stain-resistant layer arranged in sequence, wherein the process of setting the stain-resistant layer on the base material layer is: coating the stain-resistant layer on the base material layer , dried at 60-80°C for 1-2 minutes, and then cured in a UV LED light box with a curing light intensity of 800-1500mw / cm 2 , The curing time is 1-3 seconds. Among them, in order to facilitate the transportation of the produced protective film, a release film is provided on the other side of the adhesive layer, and a transparent protective film is compounded on the top of the stain-resistant layer to prevent damage. When the installation is in place, remove the release film and transparent protective film . The material thickness of each layer of the protective film is shown in Tables 5 and 6 below.

[0046] table 5

[0047]

[0048] Table 6

[0049]

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com