Monorail suspension inspection trolley

A monorail and trolley technology, which is used in motor vehicles, railway vehicles, cable railways, etc., can solve problems such as the movement of inspection equipment, and achieve the effects of good applicability, good vibration suppression performance, good slip resistance and climbing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure of the present invention is further described below

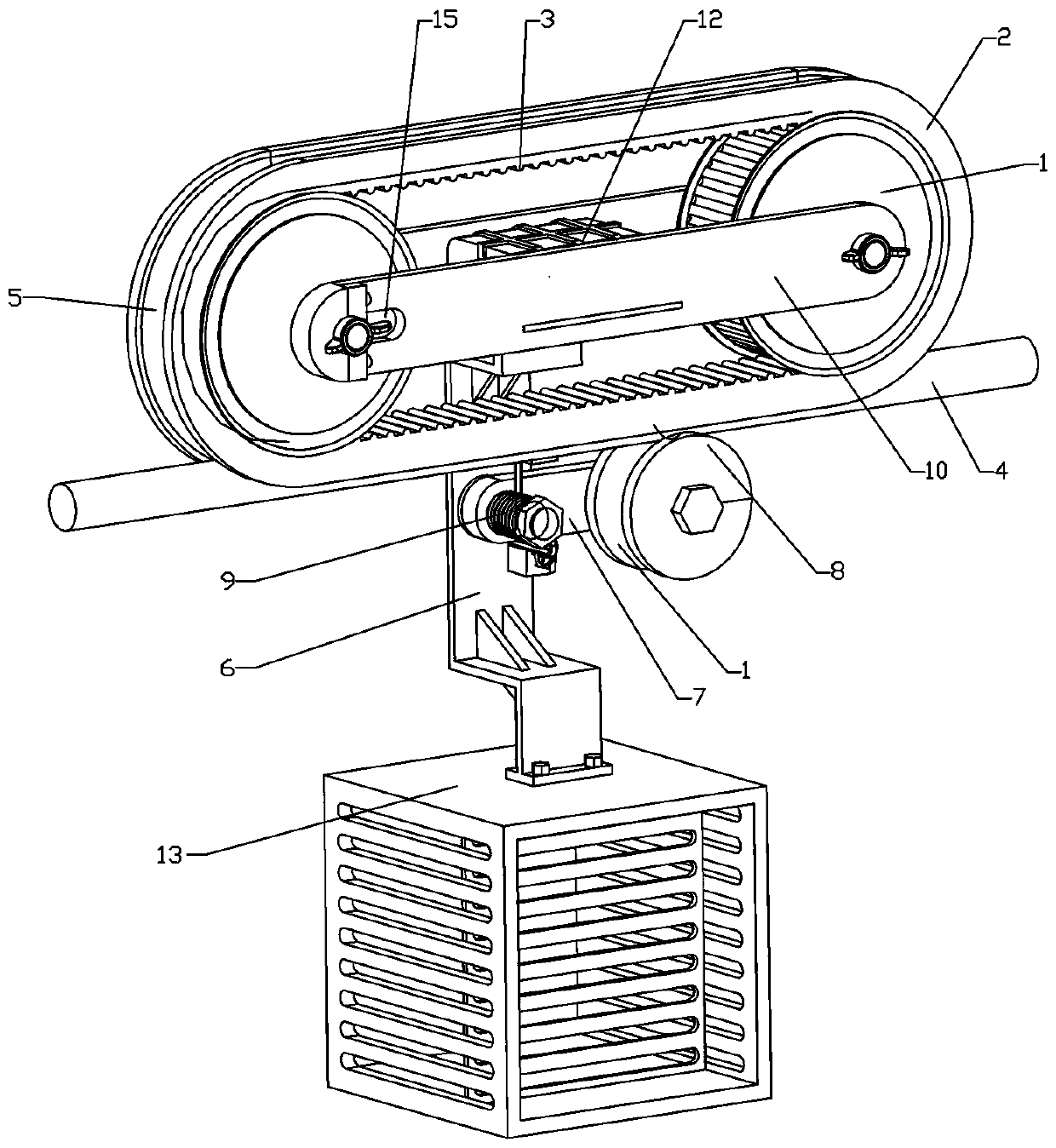

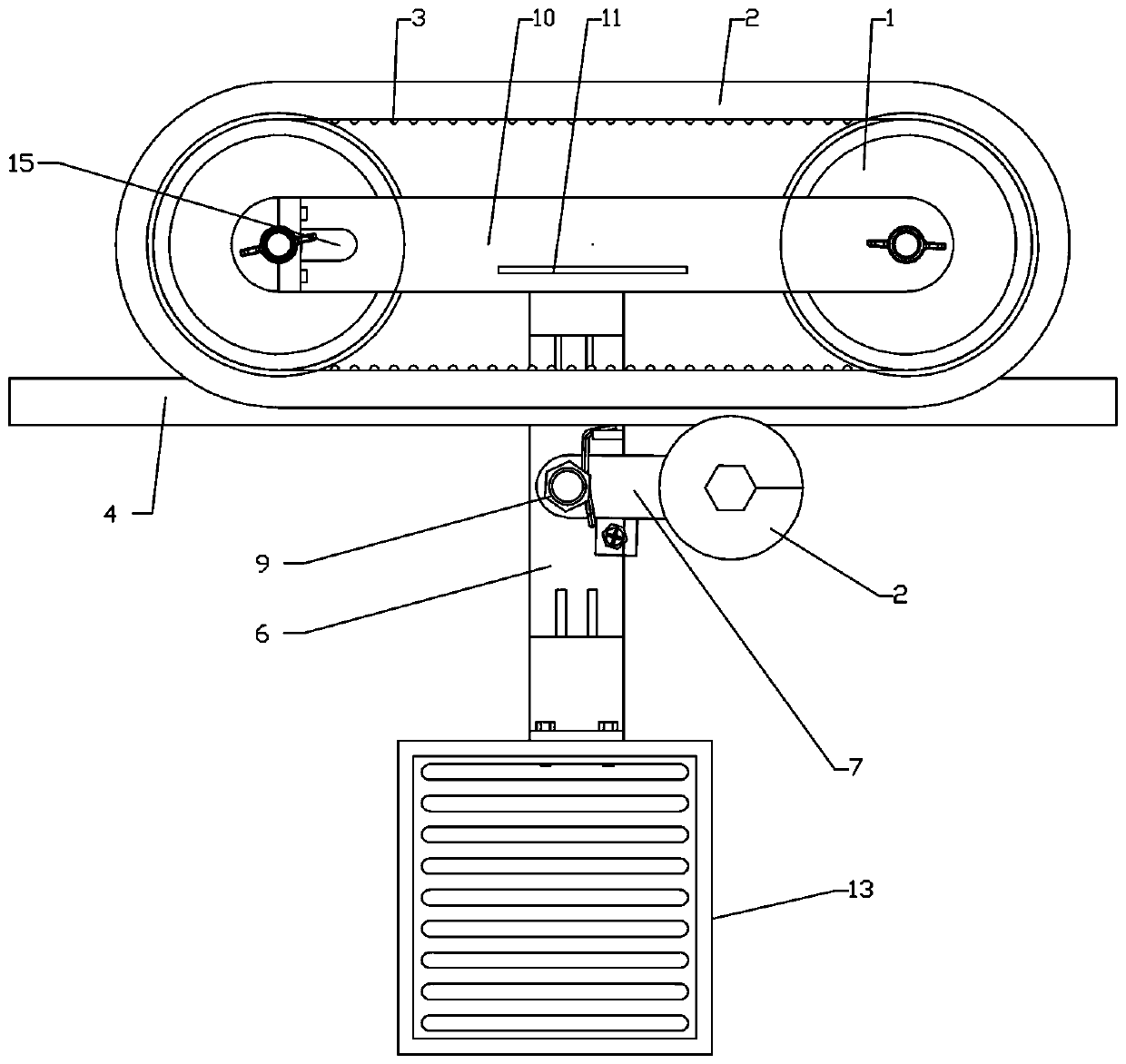

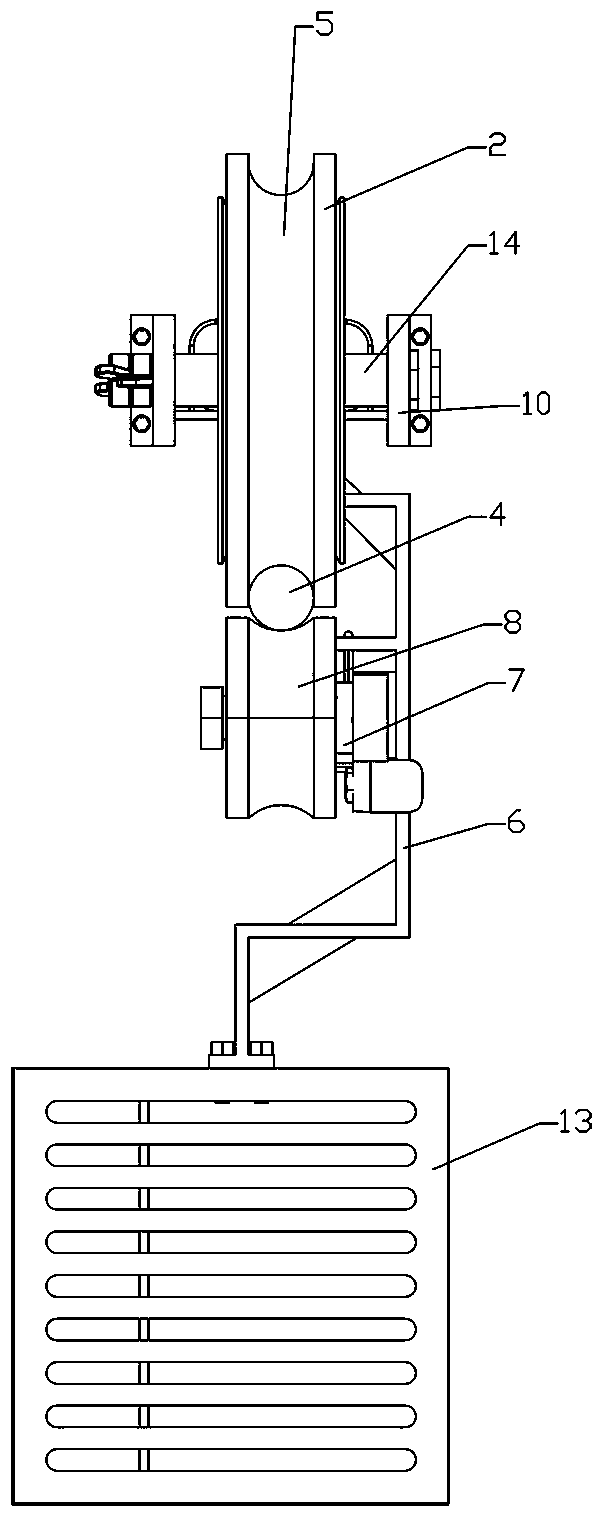

[0020] The structure of the monorail suspension inspection trolley of the present invention is as follows: Figure 1-3 As shown, it includes a front moving wheel and a rear moving wheel above the monorail track, and the two moving wheels 1 are arranged side by side along the track 4 direction. The wheel shaft 14 ends of two moving wheels 1 link to each other with the wheel frame plate 10, and the wheelbase between the two moving wheels 1 is fixed. The mobile wheel frame is provided with the wheel shaft mounting groove 15 at the wheel shaft 14 of the moving wheel 1, and the wheel shaft 14 is fixed on the outermost position of the wheel shaft mounting groove 15 at the end using a nut to keep the maximum distance between the two moving wheels.

[0021] The outer peripheral surface of the moving wheel 1 is provided with crawler belts 2 , and the inner surface of the crawler belt 2 and the outer pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com