Intelligent bin clearing and flow assisting device of inverted conical steel barrel material bin and use method thereof

An inverted cone-shaped silo technology, which is applied in the field of preventing and treating material blockage in the feed silo, to achieve the effects of uniform energy distribution, economical operation, and perfect functions for clearing the silo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

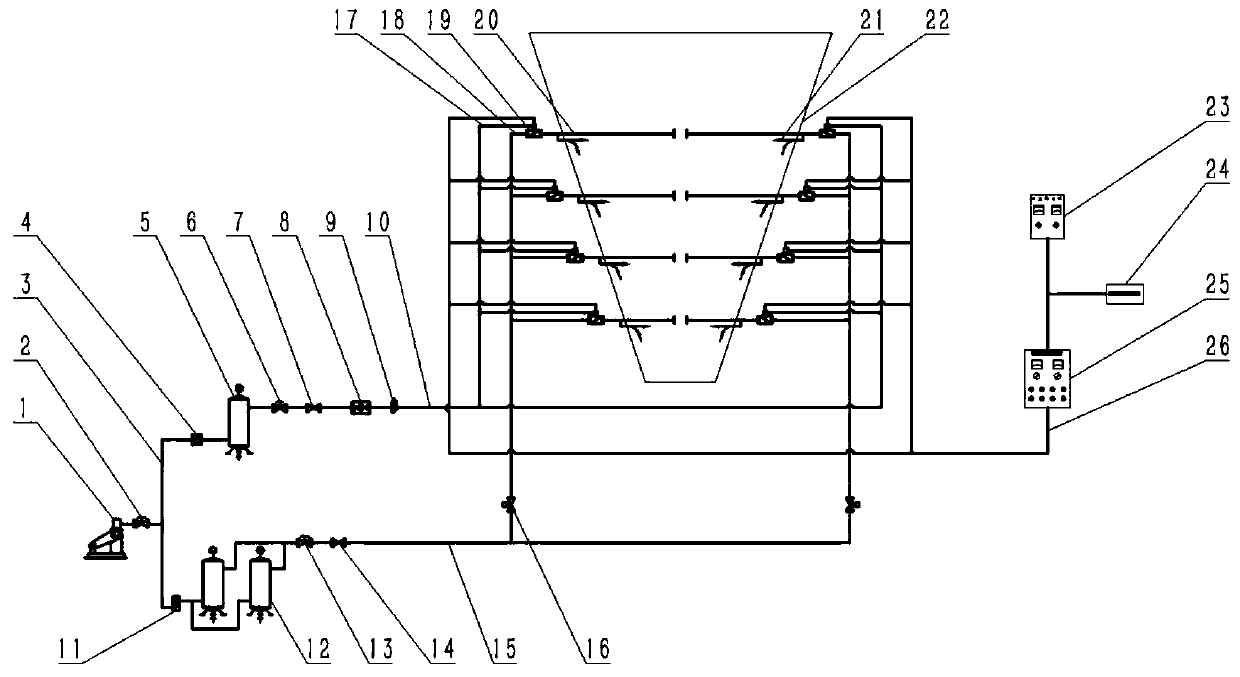

[0042] In order to further describe the present invention, the following is a further detailed description of an intelligent clearing flow-aid device for an inverted conical steel cylinder silo and its use method in conjunction with the accompanying drawings.

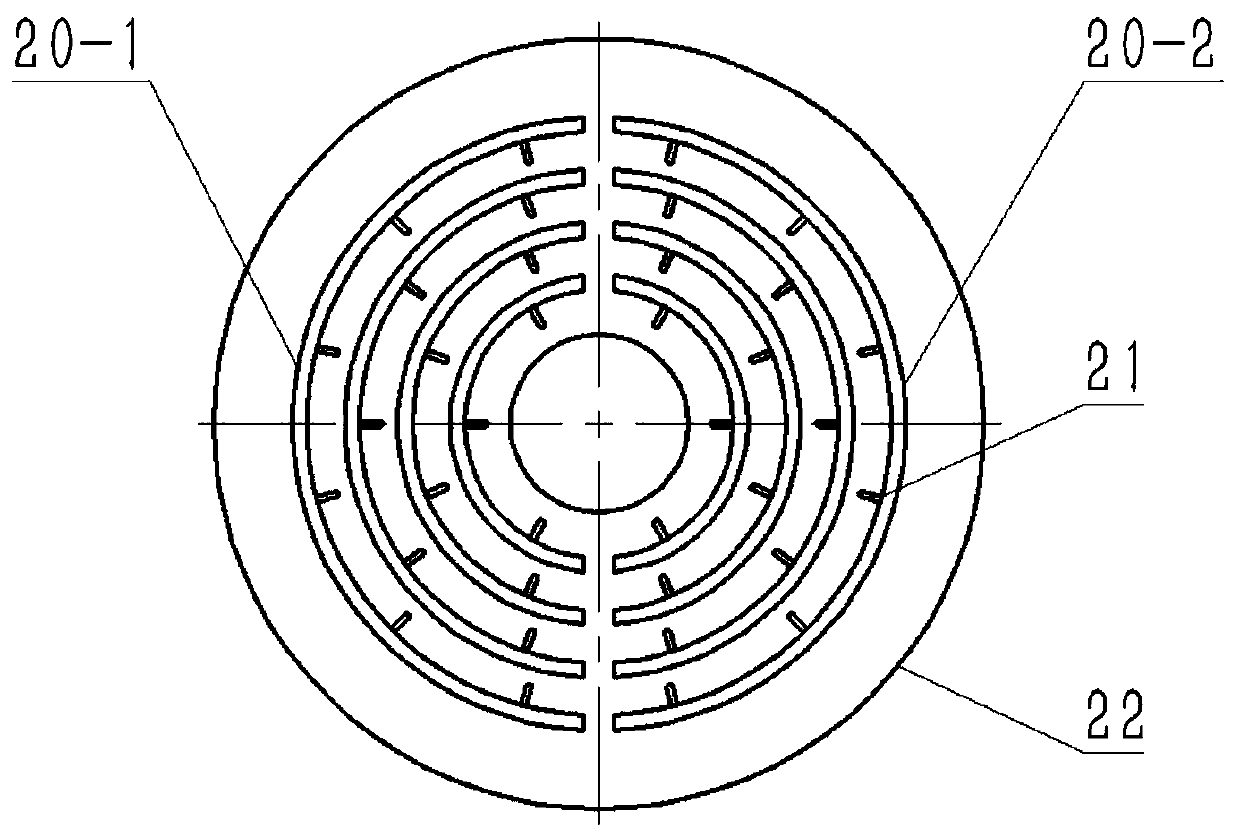

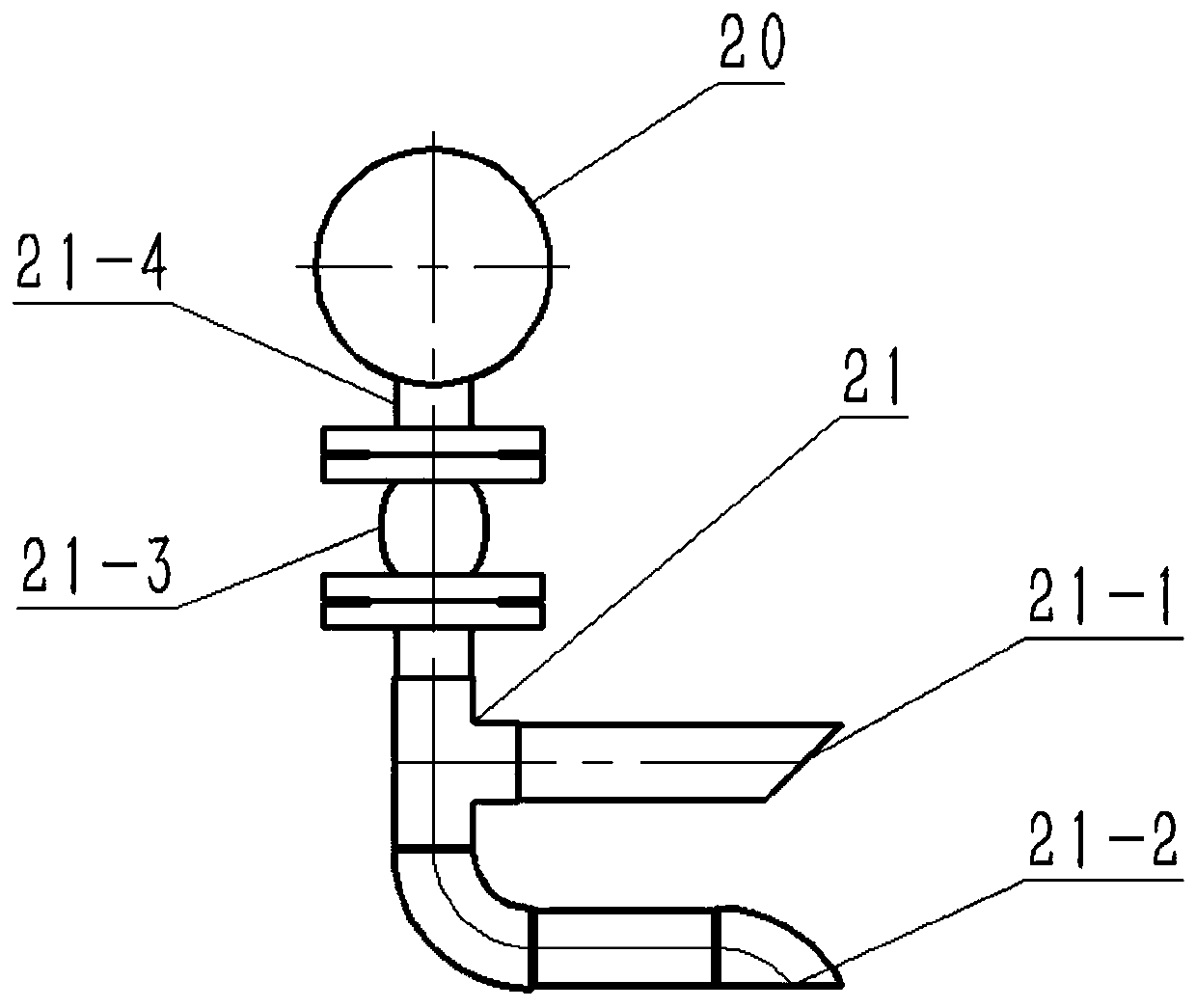

[0043] Depend on figure 1 The schematic diagram of the structural principle of an intelligent clearing and flow aid device for an inverted conical steel cylinder silo shown in the present invention and combined with figure 2 , image 3 , Figure 4 It can be seen that an intelligent clearing and flow-aiding device for an inverted tapered steel cylinder silo of the present invention is composed of an air source system, a control air path system, a flow-aiding air path system, an injection mechanism and an electric control system:

[0044] The injection mechanism includes a nozzle 21, a pneumatic butterfly valve 19, and an annular branch pipe 20 of the working gas path. The silo 22 is a steel silo with a shrinking sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com