Belt material flow control system

A flow control system and material technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as increased belt wear, increased labor costs, inability to comprehensively and continuously measure material forms, etc., to reduce Belt wear and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] First of all, those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

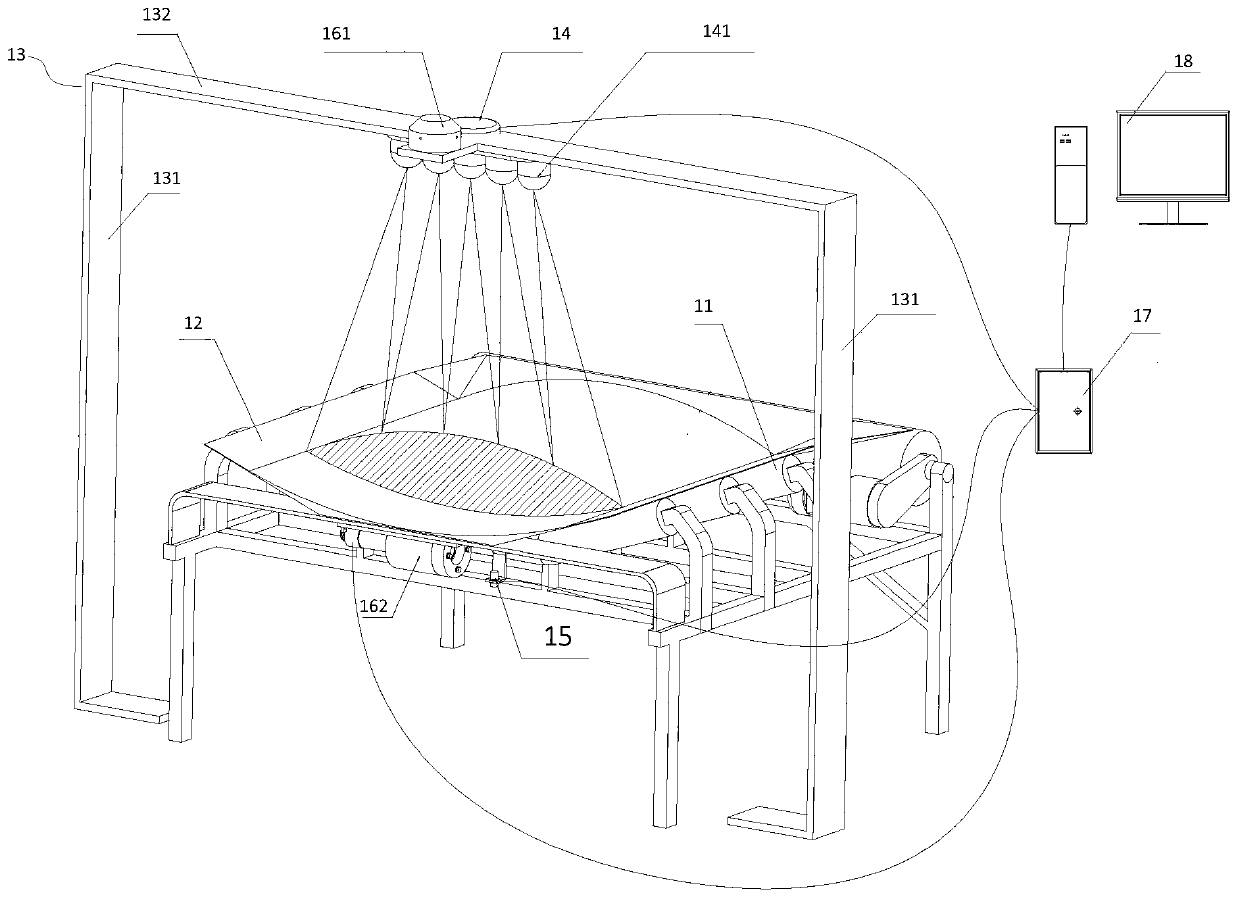

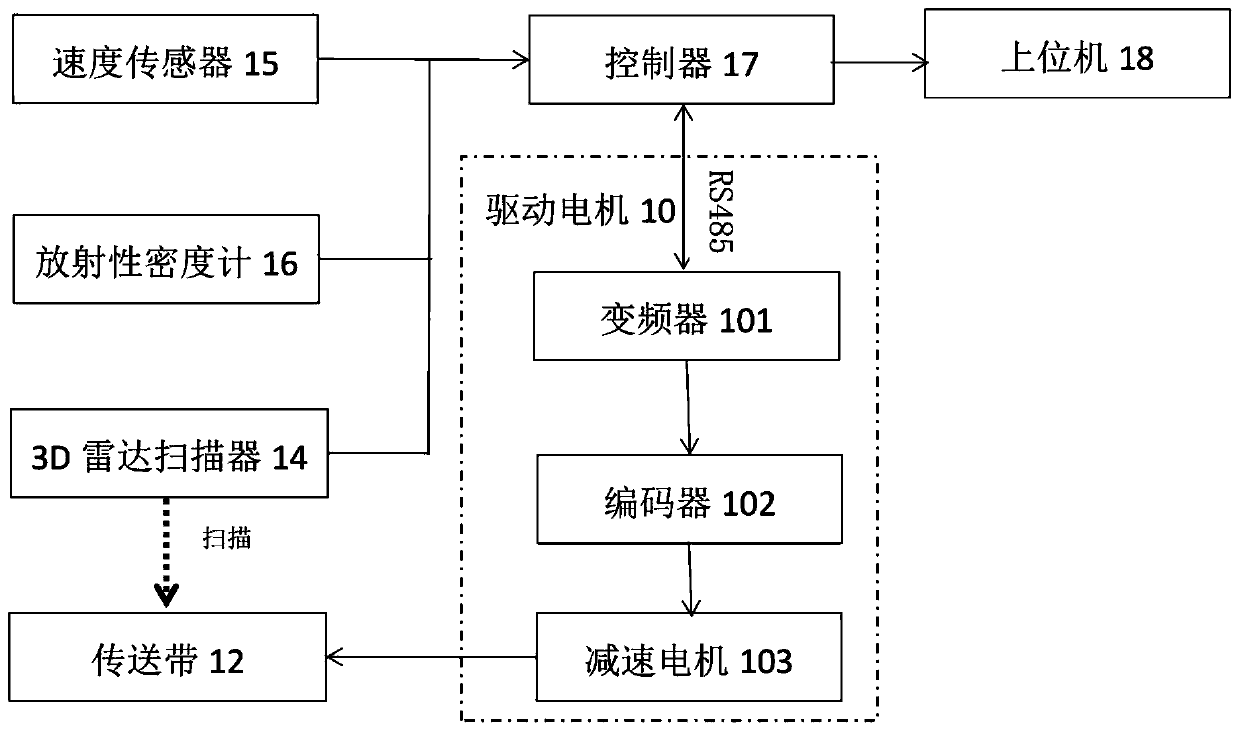

[0046] See attached figure 1 with figure 2 , figure 1 with figure 2 The main structure of a belt material flow control system is exemplarily shown. As shown in the figure, the belt material flow control system provided by the present invention may include: a driving motor 10, an idler roller 11, a conveyor belt 12, a fixed bracket 13, and a 3D radar Scanner 14, speed sensor 15, radioactive density meter 16, controller 17 and host computer 18, drive motor 10 is used to drive conveyor belt 122 to rotate, conveyor belt 12 is arranged on idler 11, 3D radar scanner 14 is fixed on fixed support 13 and above the conveyor belt 12; the 3D radar scanner 14, the speed sensor 15, the radioactive density meter 16, and the drive motor 10 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com