Vibrating flat plate bobbin yarn conveying device and bobbin yarn conveying method

A technology of conveying device and flat plate, which is applied to vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of uneven number of vibrating coils, reducing the output speed of cops, and the thickness of the cop layer before and after. Achieve the effect of improving intubation efficiency, reducing failures and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

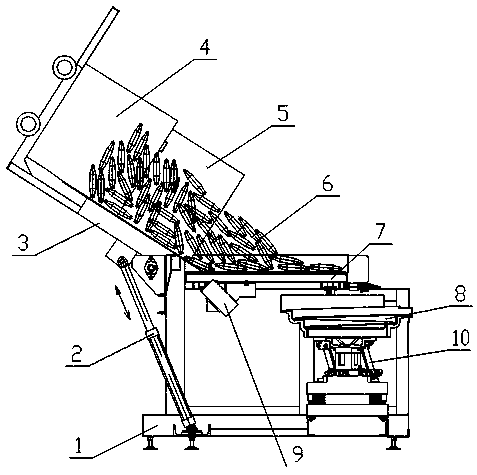

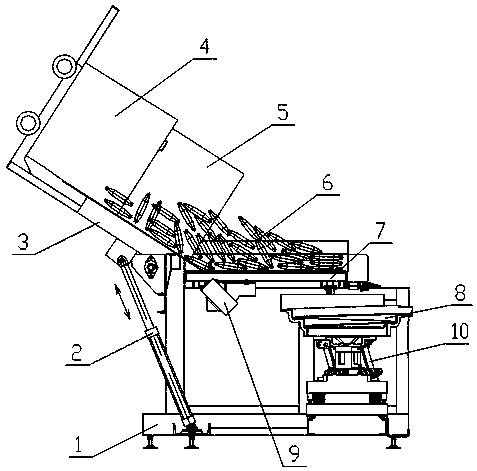

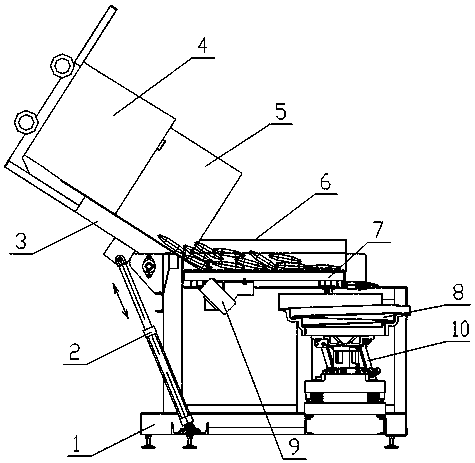

[0024] see Figure 1-Figure 4 , an embodiment of a vibrating plate bobbin delivery device of the present invention, comprising a vibrating plate 7, a plate vibrating motor 9 and a control system, a first detection sensor 11, a second detection sensor 12 and a first detection sensor 11 are set at the exit position of the above-mentioned vibrating plate 7 Three detection sensors 13, the third detection sensor 13 is higher than the second detection sensor 12, the second detection sensor 12 is higher than the first detection sensor 11, the plate vibration motor 9, the first detection sensor 11, the second detection sensor 12 and the third The detection sensors 13 are all controlled by the above-mentioned control system. The vibrating plate bobbin conveying device also includes a yarn warehouse frame 1, a hydraulic cylinder 2, a large yarn warehouse forklift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com