A construction method for underpinning a hollow floor slab to a cast-in-place floor slab

A hollow floor, cast-in-place floor technology, applied in construction, building maintenance, building construction, etc., can solve the problems of poor integrity, strength index not meeting the specification requirements, poor durability, etc., to meet the needs of renovation and long service life. , The effect of good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

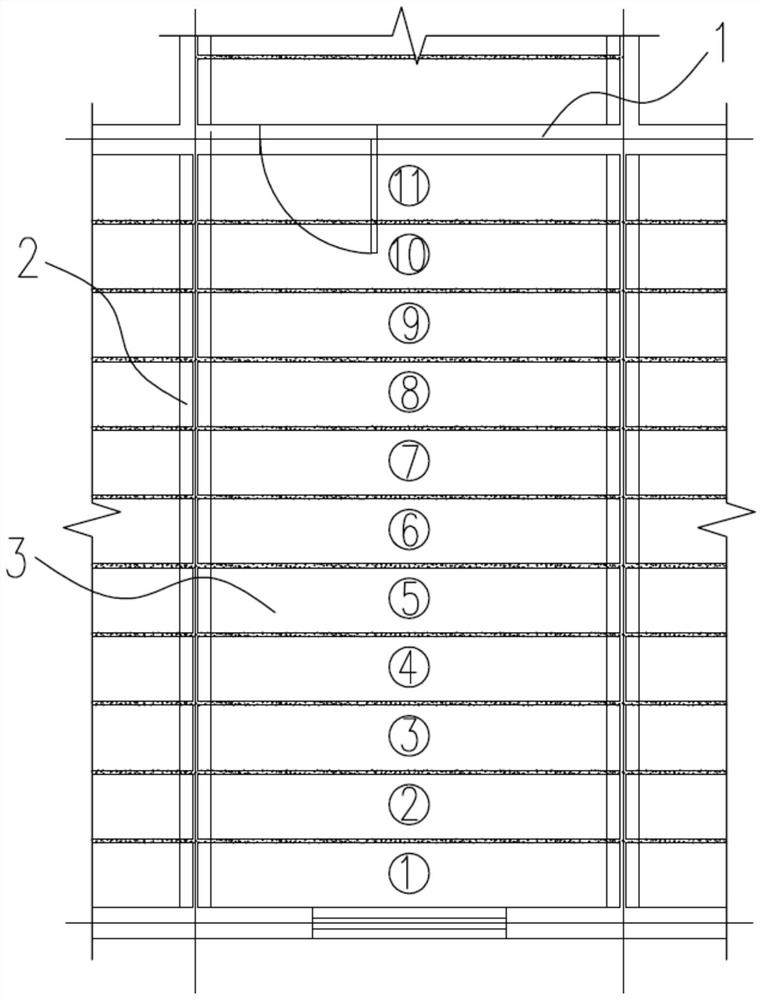

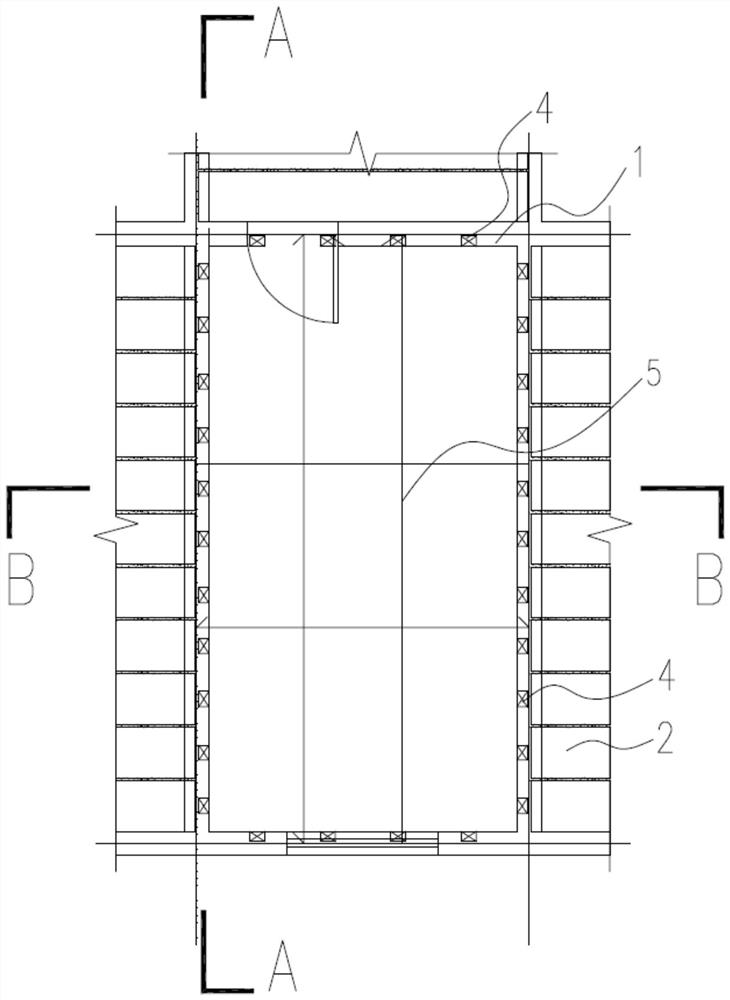

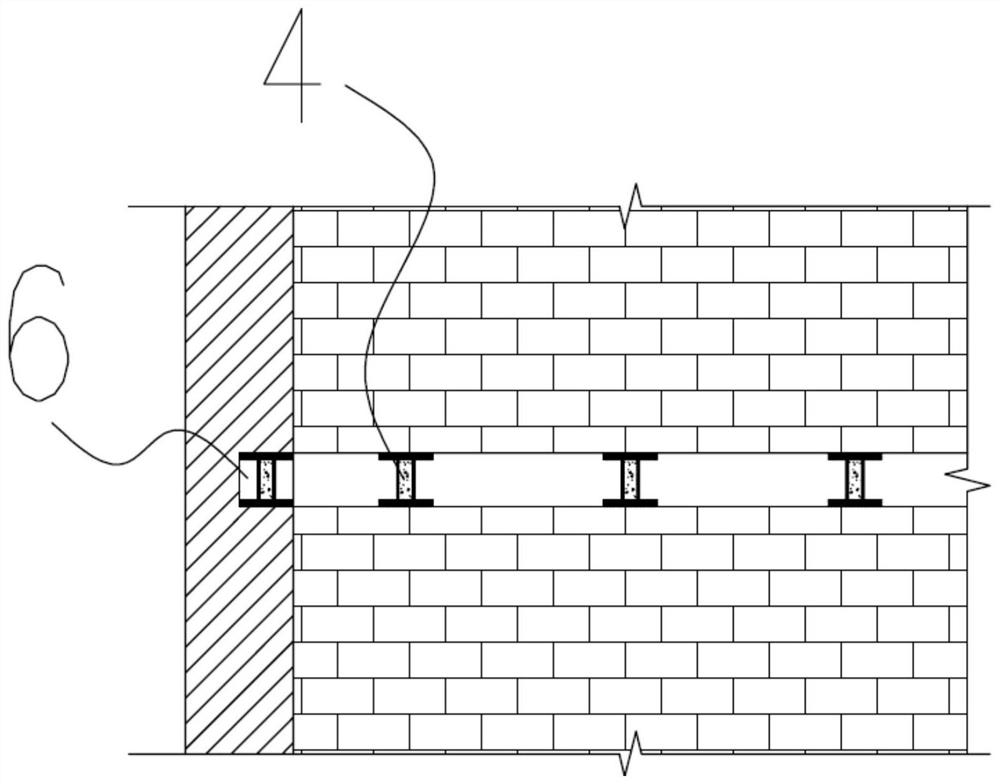

[0039] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 4 As shown, the inventive hollow floor 3 is located on the load-bearing transverse wall 2 of the building, and the vertical wall 1 of the building is located on both sides of the hollow floor 3. The construction method includes the following steps:

[0040] S1. Set up a protective net under the hollow floor 3 to be removed; prevent the chiseled hollow floor from falling directly on the lower floor, reducing the impact on the floor;

[0041] S2. Remove the hollow floor slabs 3 in the order of dismantling one at a time. The numbers of the hollow floor slabs 3 are ①, ②, ③, ④...; use the static cutting process to remove the first hollow floor slab 3, and replace the original hollow floor slab 3 Add a wall unloading support frame 4 in the middle of the gap between the support parts at both ends, and remove the hollow floor slabs 3 in sequence according to this step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com