A gel-breaking degradation method of polyacrylamide polymer fracturing fluid

A technology of polyacrylamide and fracturing fluid, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc. It can solve the problems of plugging damage, matrix permeability and fracture conductivity, and high cost, and achieve guaranteed effect, meet the needs of reservoir reconstruction, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

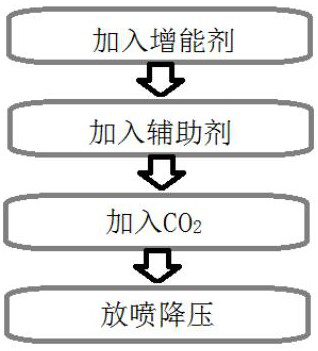

[0037] according to figure 1 A kind of polyacrylamide polymer fracturing fluid gel-breaking degradation method shown, comprises the following steps:

[0038] Step 1: Add Energizer

[0039] In the process of fracturing construction, add 0.01%-0.03% energizer of the total mass percentage of fracturing fluid;

[0040] Step 2: Add auxiliary agent

[0041] At the end of the fracturing construction after step 1 is completed, 0.05%-0.15% of the regulator, 0.01%-0.02% of the catalyst, and 0.02%-0.05% of the degradation agent are sequentially added according to the mass percentage of the fracturing fluid system;

[0042] Step 3: Join CO 2

[0043] After step 2 is completed and before the replacement fluid, inject 15-30m 3 CO 2 ;

[0044] Step 4: Release and reduce pressure

[0045] After the construction of step 3 is completed, shut down the well for at least half an hour, then use the first nozzle to discharge until the pressure drops to 8-12MPa, and then use the second nozzle...

Embodiment 2

[0063] Such as figure 1 A gel-breaking degradation method for polyacrylamide polymer fracturing fluid, which is different from Embodiment 1 in that: the first nozzle in step 4 is an 8-12 mm nozzle, and the second nozzle is a 4-8 mm nozzle.

[0064] In actual use, the first nozzle is an 8-12mm nozzle, and the second nozzle is a 4-8mm nozzle, so that the spraying and depressurization process can be carried out stably and good results can be achieved.

Embodiment 3

[0066] Such as figure 1 A polyacrylamide-based polymer fracturing fluid gel-breaking degradation method, the difference from Example 1 is that in the step 2, 0.10% of the regulator and 0.015% of the fracturing fluid system are sequentially added Catalyst, 0.035% degradation agent; Step 3 injects 20m 3 CO 2 .

[0067] In actual application, this technical solution has a fast and thorough gel breaking speed, thereby reducing the damage to the polymer fracturing fluid formation, and can also ensure the rapid degradation of the flowback fluid, which is suitable for reservoir reconstruction using the polymer fracturing fluid system The low permeability oil and gas fields are of great significance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com