A method for reducing total phosphorus content in sewage

A phosphorus content and sewage technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of large area of artificial wetland, unstable phosphorus removal effect, and sensitivity to changes in process conditions and other problems, achieve excellent phosphorus removal effect, meet the needs of equipment transformation, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

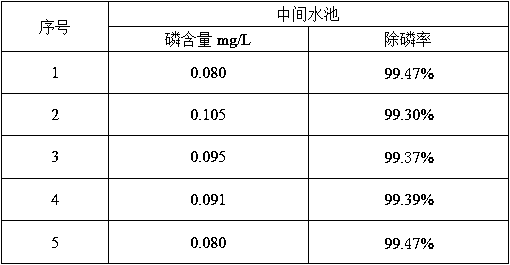

[0027] Embodiment 1 A method for reducing total phosphorus content in sewage:

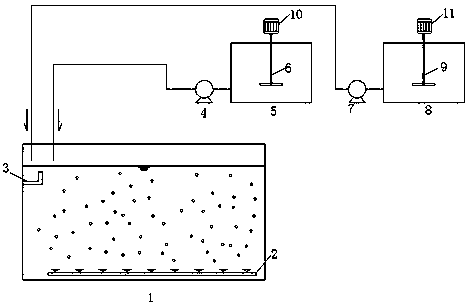

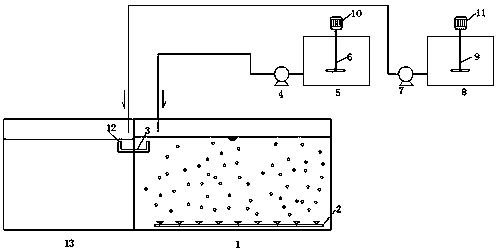

[0028] In this embodiment, aluminum sulfate and polyaluminum sulfate are all added to the outlet end of the contact oxidation tank, and the process flow diagram is as follows figure 1 shown; figure 1 Middle: 1-oxidation tank, 2-aeration pipe, 3-outlet weir, 4-phosphorus removal agent 1 metering pump, 5-phosphorus removal agent 1 dosing box, 6-phosphorus removal agent 1 stirring head, 7-phosphorus removal Agent 2 metering pump, 8- phosphorus removal agent 2 dosing box, 9- phosphorus removal agent 2 stirring head, 10- phosphorus removal agent 1 stirring motor, 11- phosphorus removal agent 2 stirring motor.

[0029] Prepare an aqueous aluminum sulfate solution with a mass concentration of 40 g / L as phosphorus removal agent 1. Add the prepared aqueous aluminum sulfate solution at the outlet of the contact oxidation tank. The volume ratio of the added aqueous aluminum sulfate solution to the sewage to ...

Embodiment 2

[0035] Embodiment 2 A method for reducing total phosphorus content in sewage:

[0036] The difference from Example 1 is that the mass concentration of the aluminum sulfate aqueous solution is 70 g / L, and the volume ratio of the added aluminum sulfate aqueous solution to the sewage to be treated is 0.0048:1; the mass concentration of the polyaluminum sulfate solution is 50 g / L, the volume ratio of the added polyaluminum sulfate aqueous solution and the sewage to be treated is 0.00048:1; the specific test results are shown in Table 2; as can be seen from Table 2, using the method of this embodiment, the total phosphorus in the treated water sample The content can reach the standard stably, and the removal rate of total phosphorus in sewage remains above 99.43%.

[0037] The detection result of table 2 embodiment 2

[0038]

Embodiment 3

[0039] Embodiment 3 A method for reducing total phosphorus content in sewage:

[0040] The difference from Example 1 is that the mass concentration of the aluminum sulfate aqueous solution is 5 g / L, and the volume ratio of the added aluminum sulfate aqueous solution to the sewage to be treated is 0.00192:1; the mass concentration of the polyaluminum sulfate aqueous solution is 25 g / L, the volume ratio of the added polyaluminum sulfate aqueous solution and the sewage to be treated is 0.00024:1; the specific test results are shown in Table 3; as can be seen from Table 3, by adopting the method of this embodiment, the total phosphorus in the treated water sample The content can reach the standard stably, but the total phosphorus content in the treated water sample is very close to the standard requirement of 0.5 mg / L, and the removal rate of total phosphorus in sewage remains above 96.8%.

[0041] The detection result of table 3 embodiment 3

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com