Data-driven marine diesel engine fault detection method

A marine diesel engine, fault detection technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of high time and labor costs, low real-time performance and detection efficiency, and difficult measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

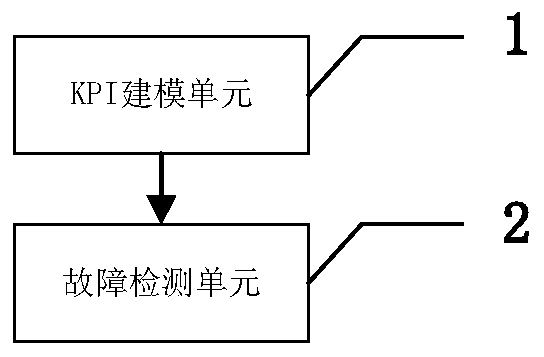

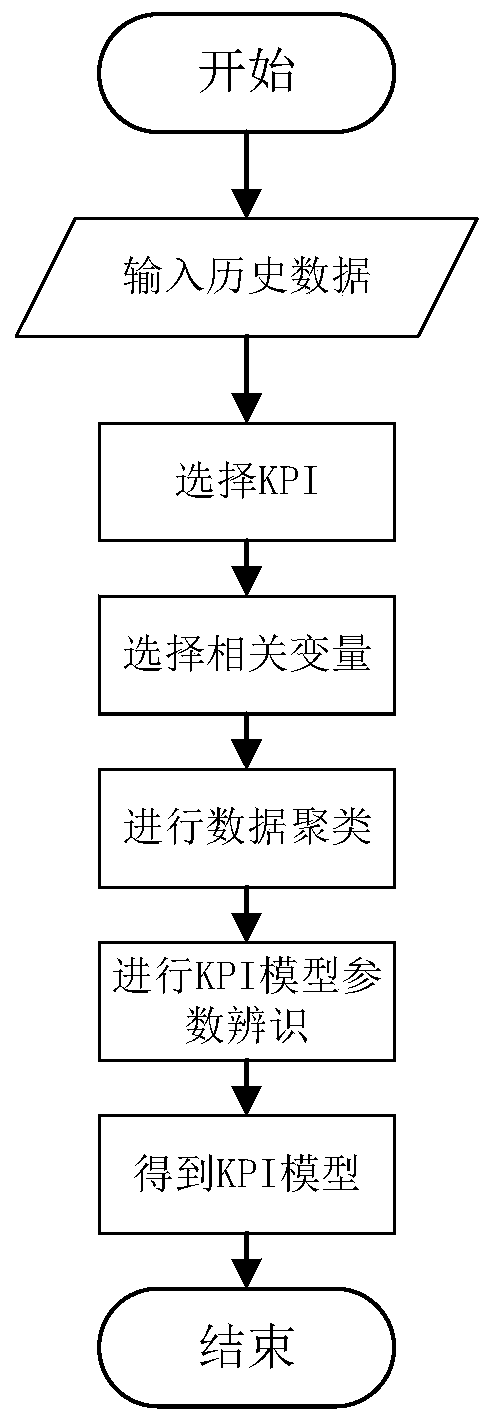

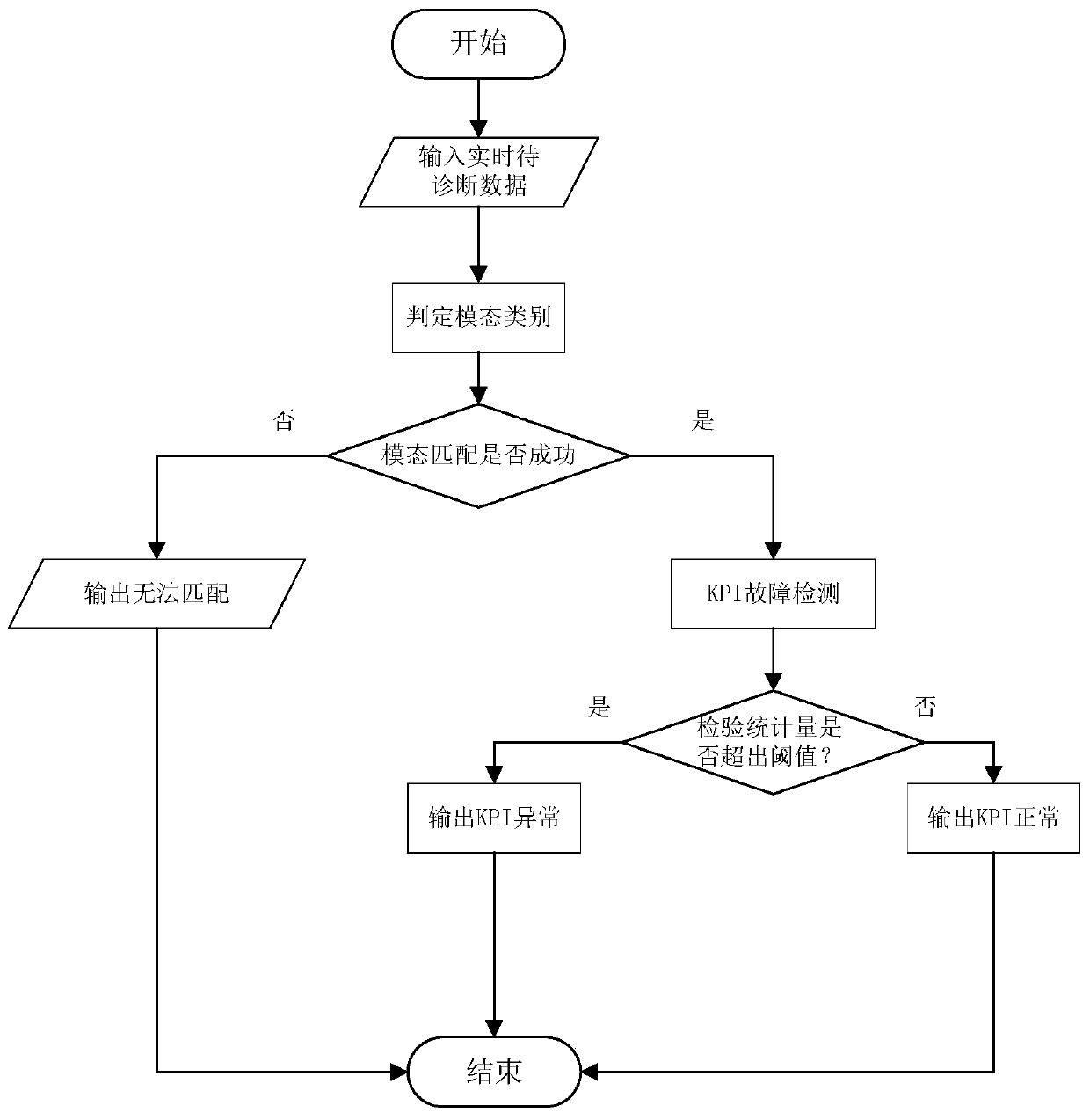

[0060] figure 1 The structure of the diesel engine fault diagnosis system provided for the concrete implementation of the present invention mainly comprises KPI modeling unit and fault detection unit; KPI modeling and fault detection method flow process are respectively as follows figure 2 , image 3 shown. In specific implementation, the KPI modeling algorithm based on the improved PLS is as follows:

[0061] 1. Collect historical data and construct a data matrix Y∈R m×N and Θ∈R l×N ;

[0062] 2. Use the standard PLS method to solve the regression coefficient M of Θ and Y;

[0063] 3. Implement singular value decomposition:

[0064] 4. Decompose the process variable space into two orthogonal subspaces:

[0065] 5. Design T 2 Statistics: threshold

[0066] 6. Detect faults accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com