Hydro-generator carbon brush and collecting ring current-carrying frictional wear simulation test device and method

A hydro-generator, current-carrying friction technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of excessive brush temperature, uneven wear, time-consuming and labor-intensive, etc., to reduce mechanical vibration and realize real-time The effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

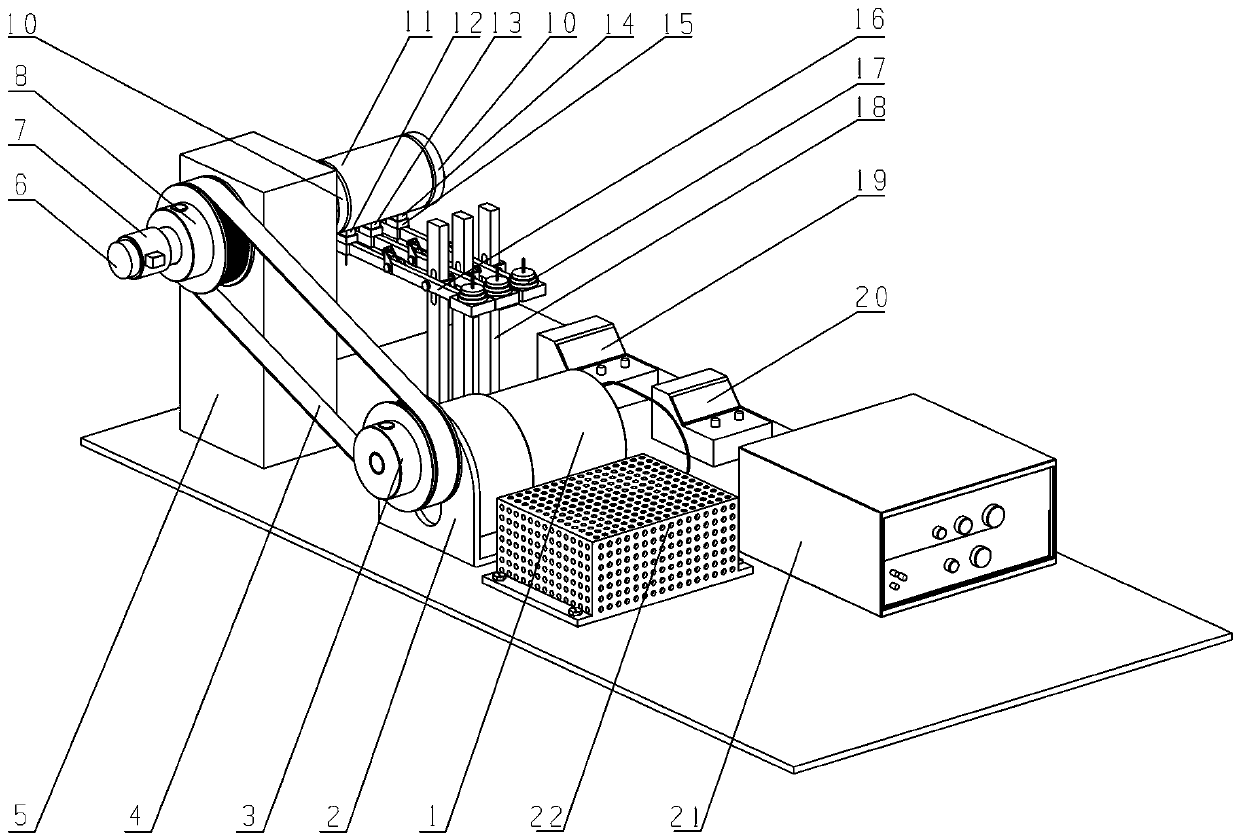

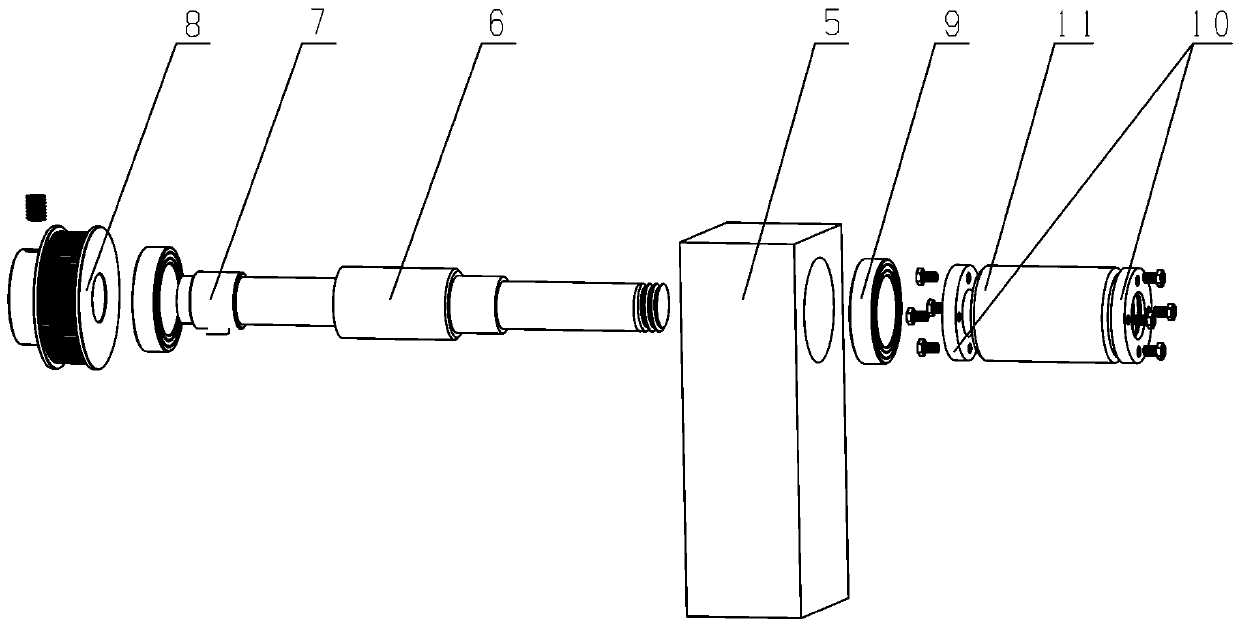

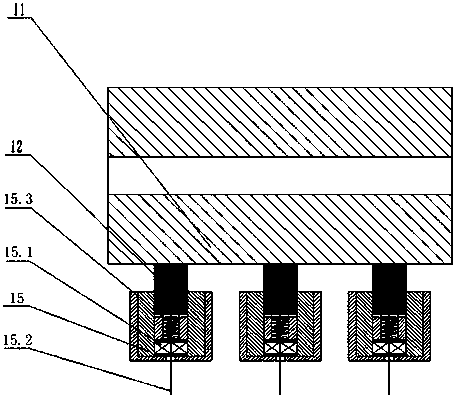

[0040] see Figure 1-6 , the current-carrying friction and wear simulation test device for the carbon brush of the hydro-generator and the collector ring, which includes a support system for supporting and installing the entire device; the drive system for providing power is fixedly installed on the support system, and the drive system A slip ring 11 is installed at the main shaft output end of the slip ring 11; three carbon brushes of the same type are arranged at the lower end of the slip ring 11, which are respectively an anode carbon brush 12, a cathode carbon brush 14 and an auxiliary carbon brush 13; a plurality of the carbon brushes The brushes respectively contact and cooperate with the brush holders 15 installed on a plurality of corresponding levers 16, the brush holders 15 are connected with the levers 16 through bolts, and the plurality of levers 16 are respectively supported on the vertical brackets 18 of the bracket system; The ring 11 and a plurality of carbon b...

Embodiment 2

[0052] The method for carrying out the hydroelectric generator carbon brush and slip ring wear test on the current-carrying friction and wear test bench is characterized in that it includes the following steps:

[0053] Step 1: When conducting the friction pair test between the carbon brush and the collector ring 11, respectively install the anode carbon brush 12, the cathode carbon brush 14 and the auxiliary carbon brush 13 on the corresponding brush holder 15;

[0054] Step 2: Install the collector ring 11 and the coaxial insulating ring 10 on the output end of the main shaft 6 through screw connection, adjust the position of the lever 16 on the vertical support 18, and ensure that the carbon brush and the collector ring 11 are in good contact;

[0055] Step 3: Connect the drive system circuit, start the speed regulating motor 1, drive the active synchronous pulley 3 through the speed regulating motor 1, drive the driven synchronous pulley 8 through the active synchronous pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com