Method for evaluating welding residual stress

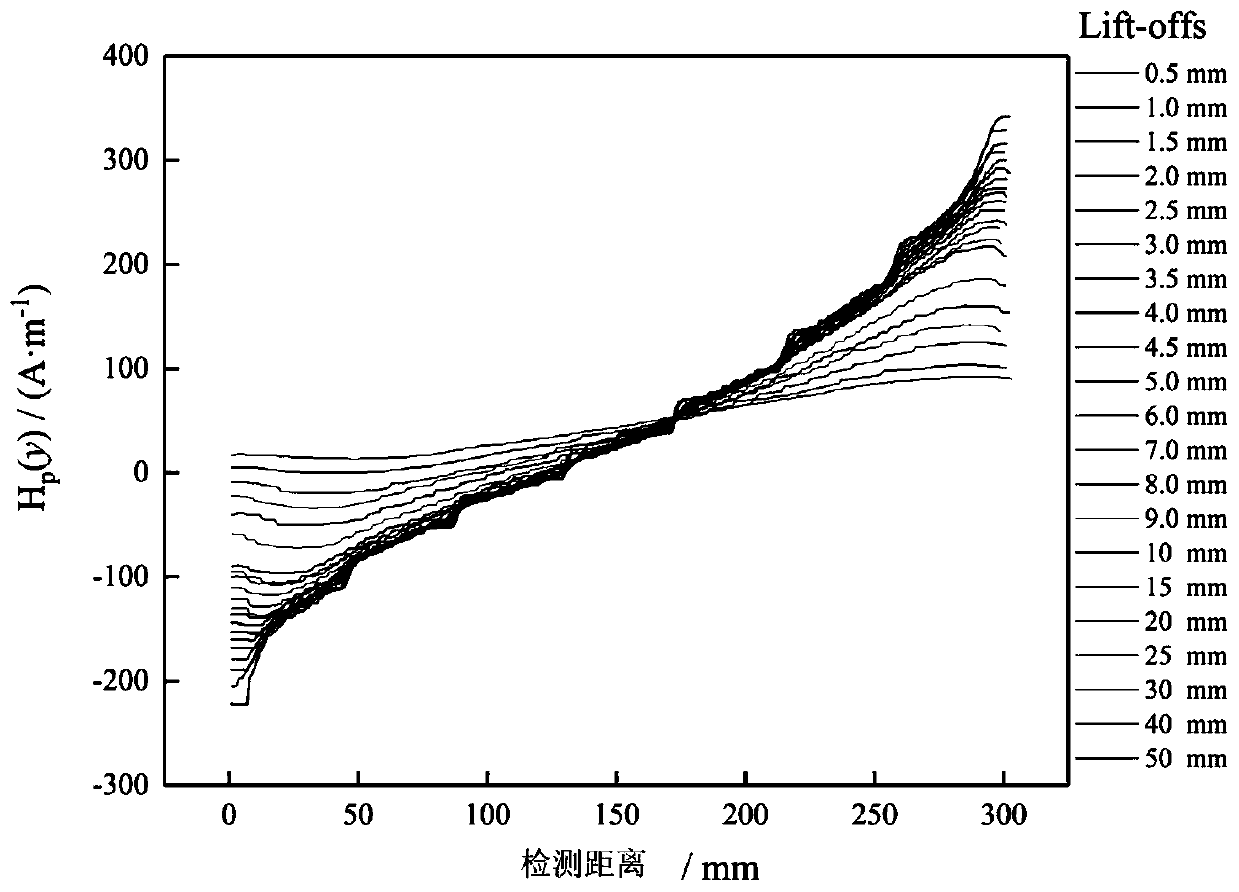

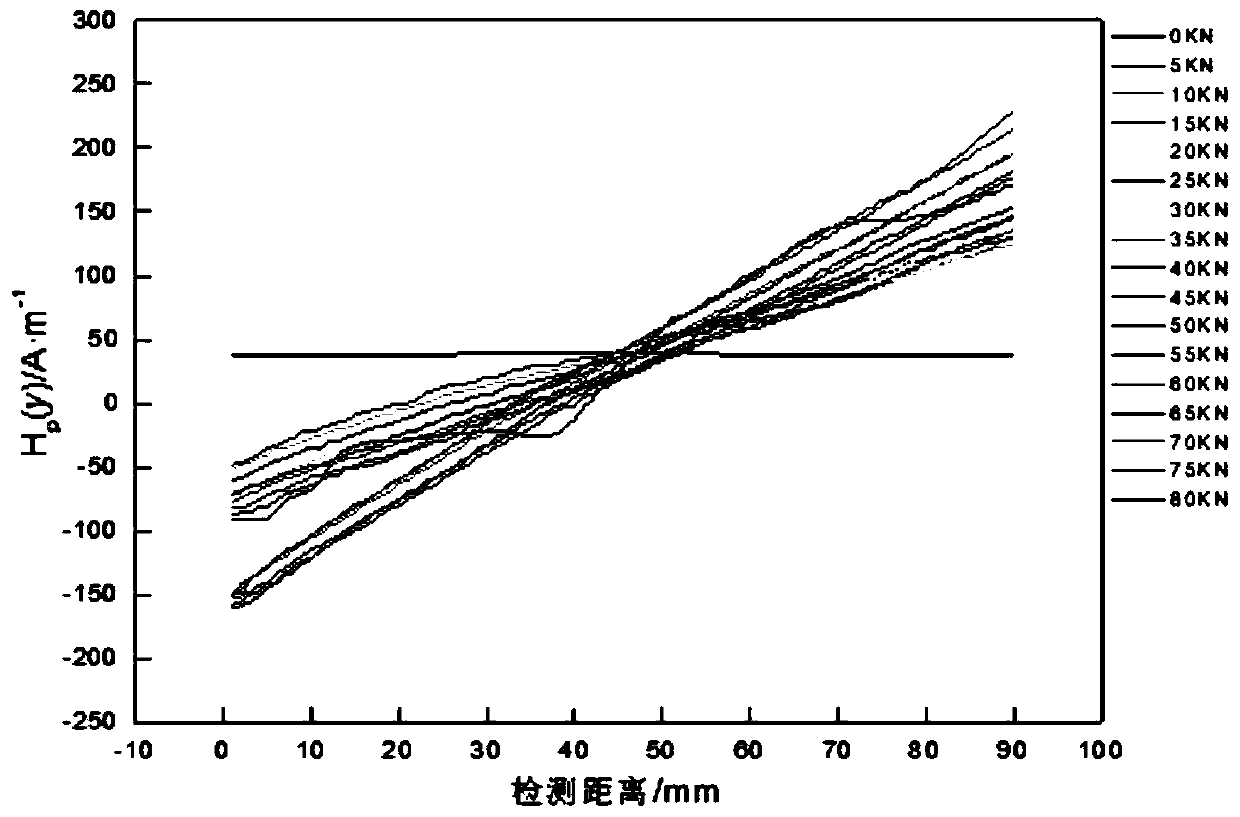

A technology of residual stress and stress, applied in the field of residual stress evaluation, can solve problems such as inability to realize on-site, fast, online application, complexity of welding residual stress, etc., and achieve the effect of quantitative evaluation and lift-off height optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] The method for welding residual stress evaluation of the present invention comprises the following steps:

[0025] Step 1: Select hot-rolled Q235 steel with a thickness of 3.0mm as the welding base material, carbon steel welding wire as the additive material, and a mixed gas of 82% argon and 18% carbon dioxide as the shielding gas to adjust the welding process parameters, mainly for welding Current, arc voltage, gas flow, dry elongation of welding wire, welding speed, to obtain welded joints without appearance and internal defects;

[0026] Step 2, process and prepare Q235 steel with a size of 200×30×3mm, and prepare rectangular grooves with a width of 0.5mm and depths of 0.5, 1.0, 1.5, 2.0 and 2.5mm on its surface by wire cutting method, and the distance between them is 30mm, and the vacuum heat treatment method is used to relieve the stress of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com