Method for improving phased array ultrasonic detection capability of R region of complex-shaped component

A complex shape, ultrasonic detection technology, applied in the processing of detection response signals, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, etc., can solve the problems of insufficient lateral resolution and unsatisfactory detection results, and improve the lateral The effect of detection resolution, improvement of detection ability, and improvement of lateral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

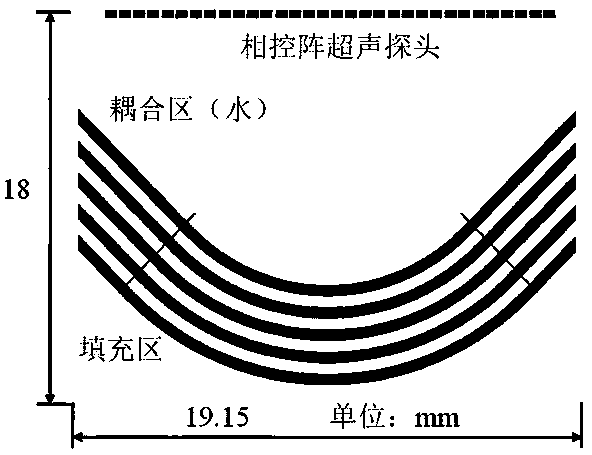

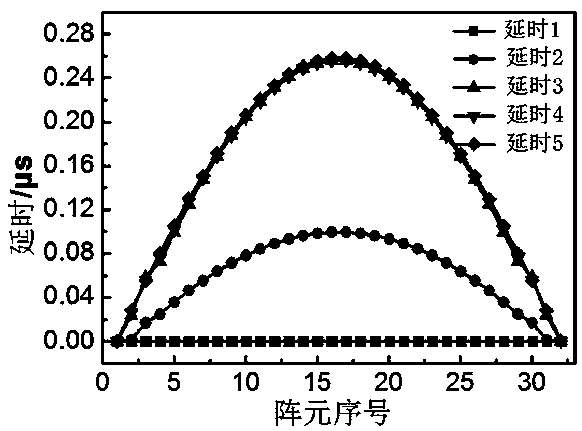

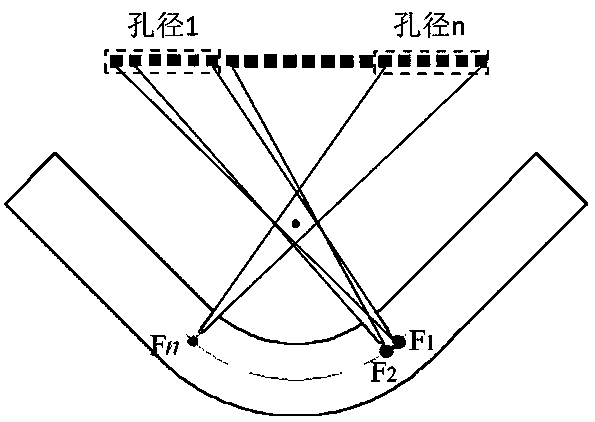

[0025] (1) Establish a finite element simulation model

[0026] For the T-shaped truss sample of CFRP material, the density of the sample was measured by the Archimedes drainage method to be 1542 kg / m 3 ; According to the metallographic method, the thickness of the single layer of the sample is 0.15 mm, and the total number of layers is 40 layers, of which the R area part is 20 layers, and the layering sequence is [45° / 90° / -45° / 0°]5 , the total thickness is 3.0 mm, the radius of curvature of the R zone is 5 mm, and the center angle is 90°. The ultrasonic liquid immersion back reflection method is used to measure the sound velocity of CFRP material T-shaped stringer corresponding to the different directions of the one-way plate sample, and then the elastic stiffness matrix of the one-way plate layer in the 90° direction is obtained through the inversion of the simulated annealing algorithm, and then the bond transformation is carried out. The elastic stiffness matrices of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com