Multi-level inventory control method and system for engineering materials

A technology of inventory control and materials, applied in the field of engineering management, can solve the problems of delaying the construction period, increasing the overall cost of the project, and scattered management of engineering materials inventory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

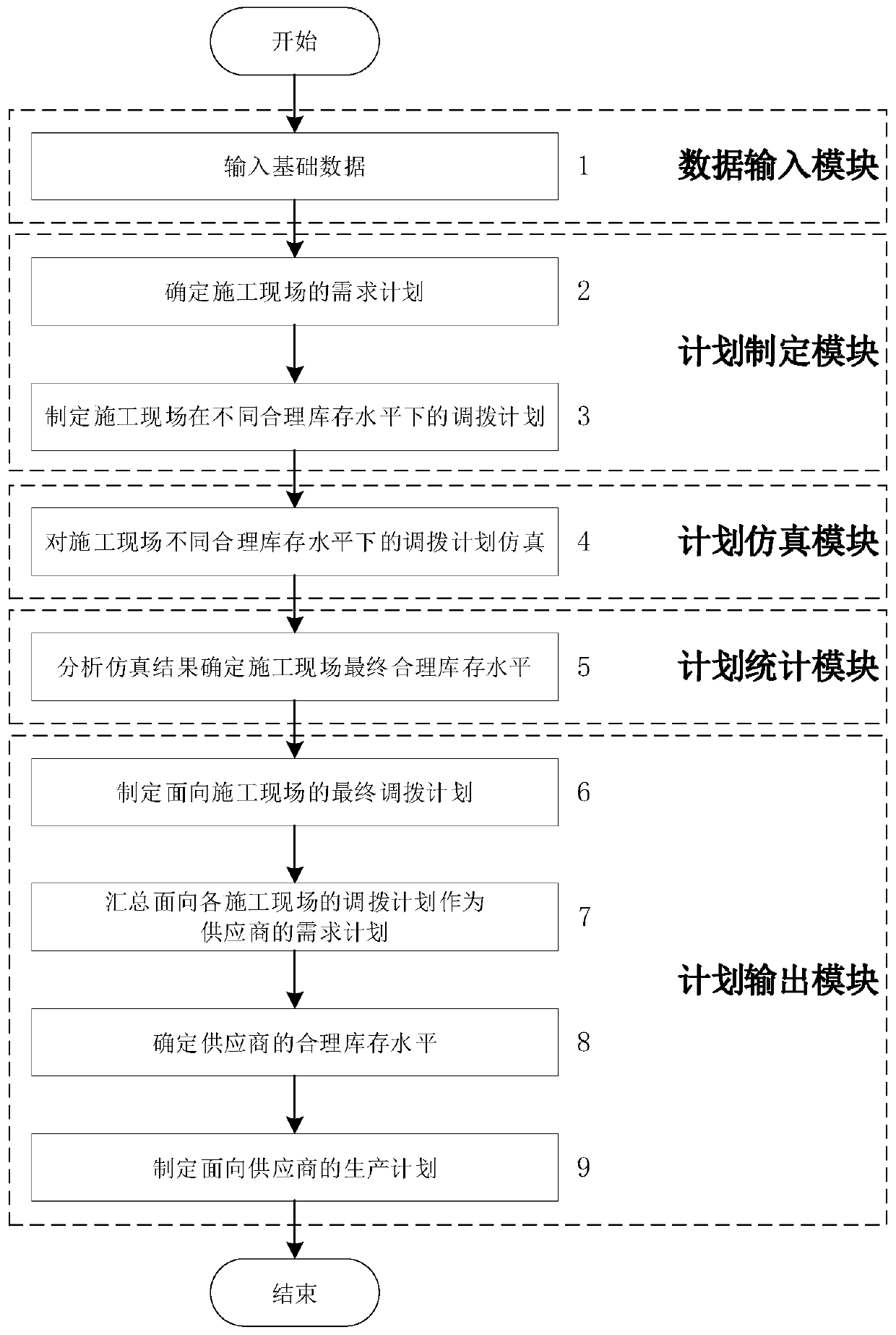

[0065] Taking the multi-level inventory plan of bulk silicon cement in a certain project in April 2018 (project month) as an example, as follows figure 1 As shown, a kind of project materials multi-level inventory control method of the present invention, concrete steps comprise as follows:

[0066] 1. Data input module (including step 1 and one step)

[0067] Step 1: Enter basic data

[0068] The engineering material supply chain of the embodiment consists of one supplier and three construction sites. Basic data includes construction site historical data and planned monthly parameters. Among them, the historical data of the construction site specifically refers to the actual daily consumption of materials on the construction site in the past; the planned monthly parameters include the start and end time of the planning period, the monthly planned quantity of the construction site, the initial inventory of the construction site, the initial inventory of suppliers, supply The...

Embodiment 2

[0113] A multi-level inventory control system for engineering materials, including: a data input module, a plan formulation module, a plan simulation module, a plan statistics module, and a plan output module;

[0114] Wherein, the data input module is used to input the historical data of the construction site and the parameters of the planned month, wherein the historical data of the construction site is specifically the actual daily usage of materials on the construction site in the past; wherein the parameters of the planned month are specifically: The start and end time of the period, the monthly planned quantity of the construction site, the beginning inventory of the construction site, the beginning inventory of the supplier, the monthly planned quantity of other items supplied by the supplier, the minimum order quantity of the construction site, and the maximum daily supply of the supplier Quantity, supplier's one-time production quantity, each lead time of the multi-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com