Optical camera lens

A camera and lens technology, applied in the field of cameras, can solve the problems of poor heat conduction effect, out-of-focus lens, poor heat conduction effect between the lens cover and the lens holder, etc., and achieves the effect of solving lens fogging and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

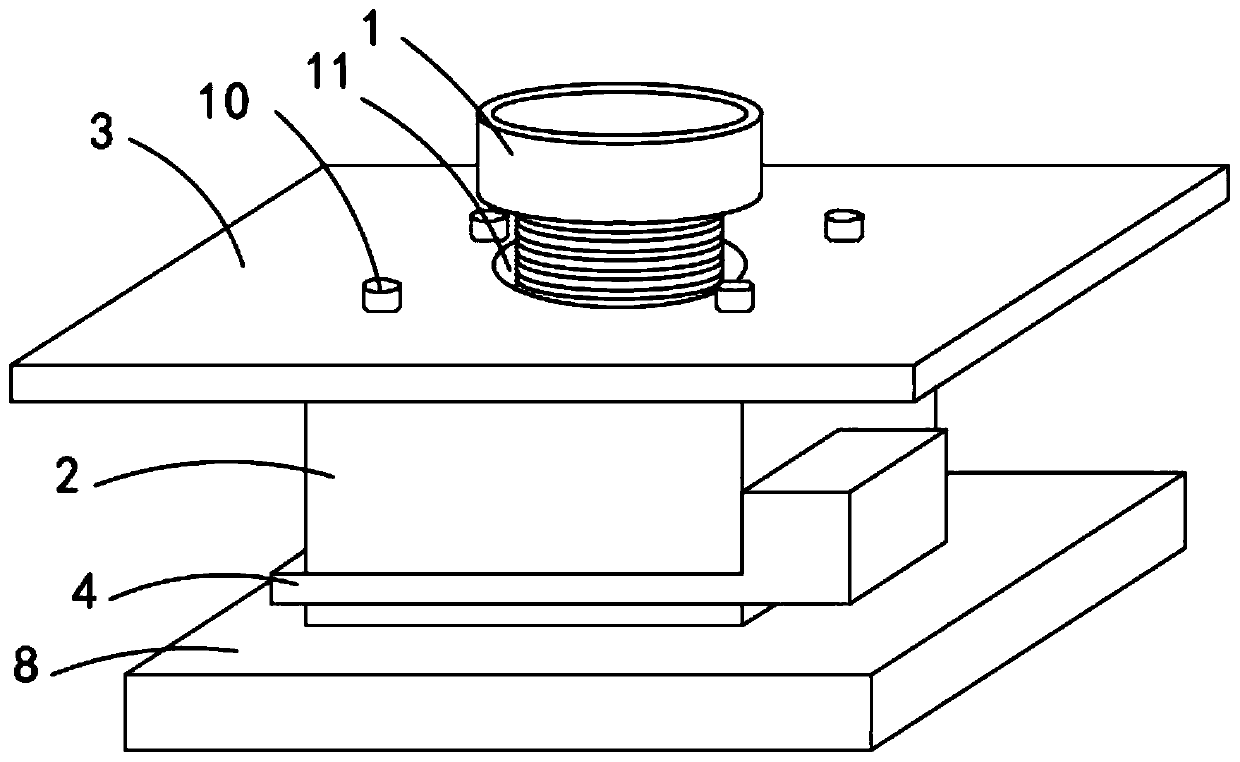

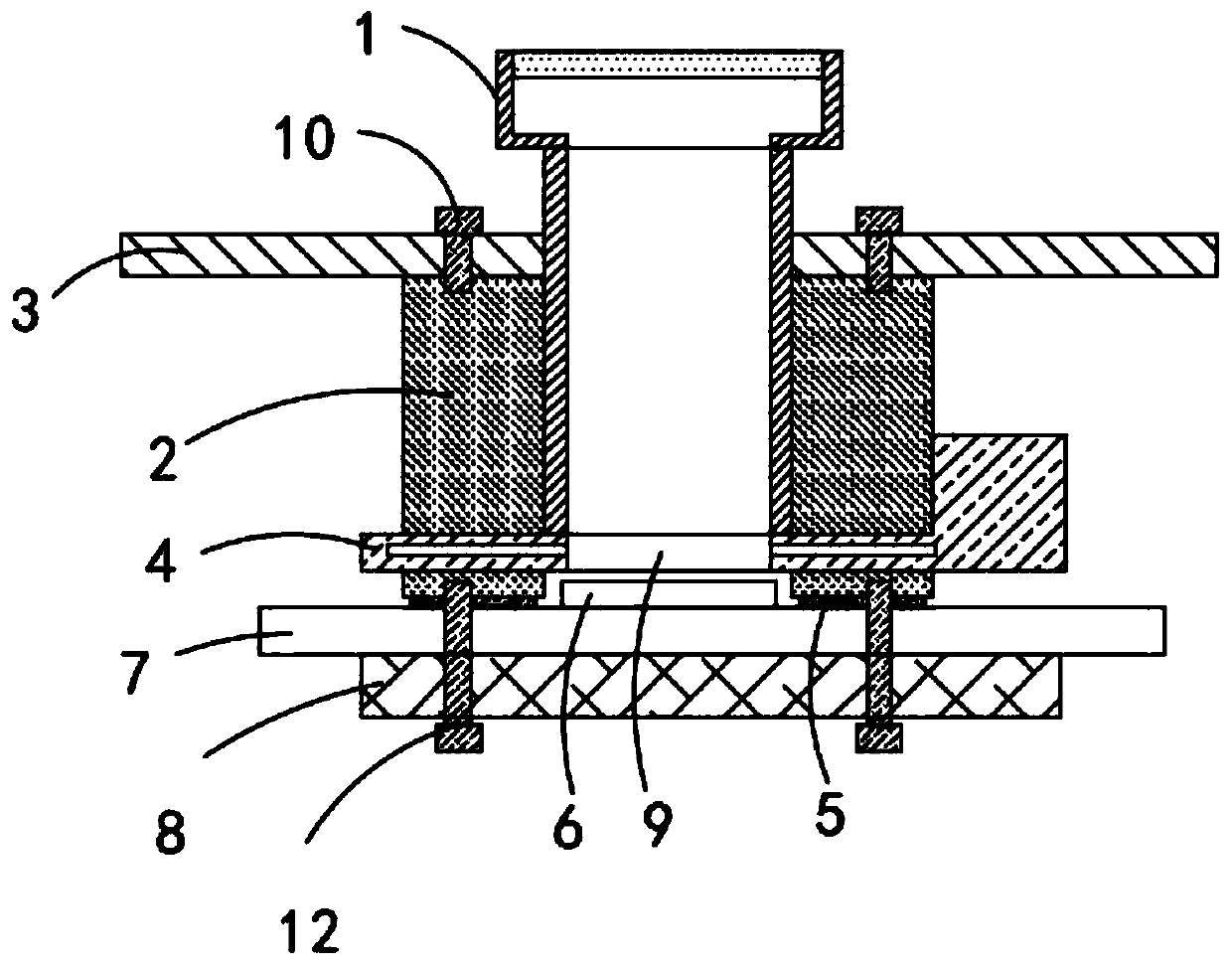

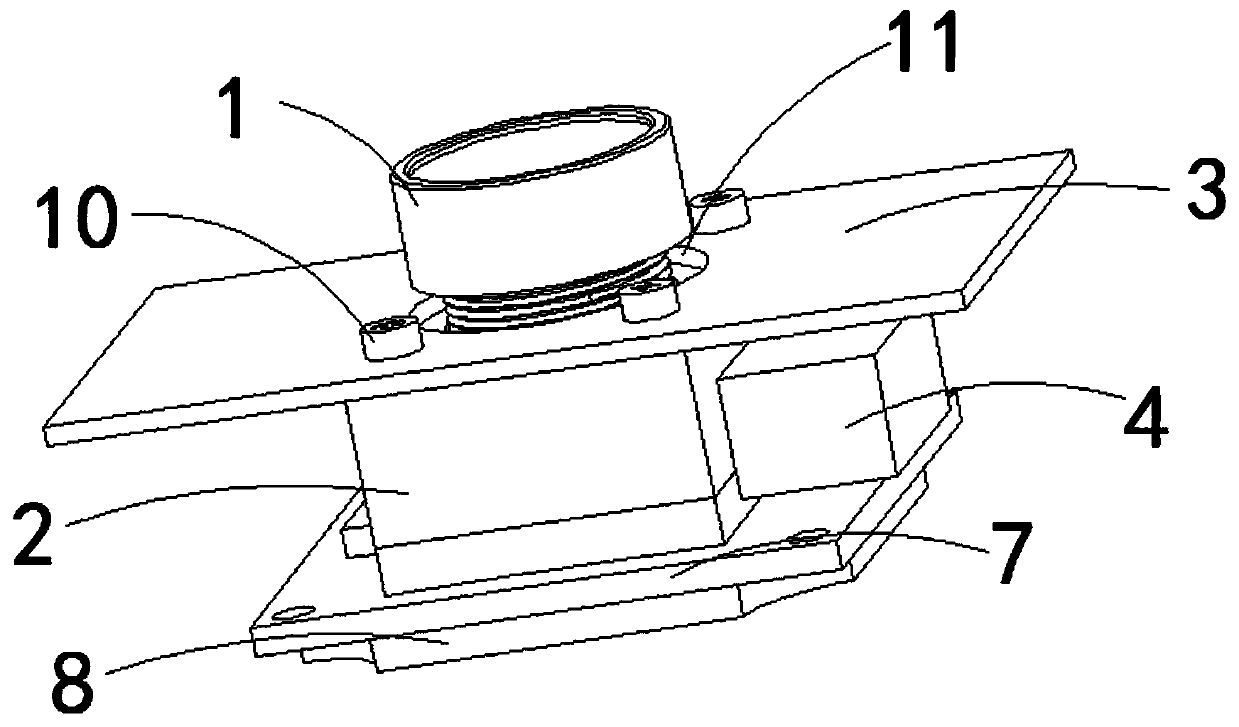

[0024] see Figure 1-4 , an optical camera lens, including a lens 1 and a lens holder 2, the thread between the lens 1 and the lens holder 2 is added with thermally conductive silicone gel, and the thermally conductive silicone gel is based on two-component A and B-component silicone oil. Add 300%-1000% of thermally conductive fillers to components A and B separately by mass percentage. Thermally conductive fillers include alumina, magnesia, and boron nitride. Semi-fluid thermal conductivity: 1–5W / m*K, temperature resistance -40-200°C, fireproof 94V0 heat conduction paste material, before the lens and lens mount lock screw are assembled, apply a film on the lens thread 1:1 and mix AB group The heat-conducting silicone gel can be assembled after the heat-conducting silicone gel is divided. The heat-conducting silicone gel can play the role of caulking. In addition, the heat-conducting silicone gel is self-adhesive. Internal thread, the surface of lens 1 is provided with extern...

Embodiment 2

[0026] see Figure 1-4 , an optical camera lens, including a lens 1 and a lens holder 2, the thread between the lens 1 and the lens holder 2 is added with thermally conductive silicone gel, and the thermally conductive silicone gel is based on two-component A and B-component silicone oil. Add 300%-1000% of thermally conductive fillers to components A and B separately by mass percentage. Thermally conductive fillers include alumina, magnesia, and boron nitride. Semi-fluid thermal conductivity: 1–5W / m*K, temperature resistance -40-200°C, fireproof 94V0 heat conduction paste material, before the lens and lens mount lock screw are assembled, apply a film on the lens thread 1:1 and mix AB group The heat-conducting silicone gel can be assembled after the heat-conducting silicone gel is divided. The heat-conducting silicone gel can play the role of caulking. In addition, the heat-conducting silicone gel is self-adhesive. Internal thread, the surface of lens 1 is provided with extern...

Embodiment 3

[0028] Based on Examples 1 and 2, such as figure 2 , a support plate 3 is provided above the lens holder 2, and a circular opening 11 that penetrates up and down is provided in the middle of the support plate 3. The upper end of the lens 1 is provided with a circular head 11 and extends to the top. A plurality of second fixing bolts 10 are provided, and the support plate 3 and the lens holder 2 are threadedly connected by the second fixing bolts 10. The support plate 3 is made of copper or aluminum material, and the setting of the support plate 3 can improve the heat conduction effect.

[0029] Working principle: when in use, the scene is projected onto the surface of the image sensor 6 through the optical image generated by the lens 1, and then converted into an electrical signal through the pcb circuit board 7, and then converted into a digital image signal after A / D conversion, and then sent to the digital processing chip After processing, the lens holder 2 is changed from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com