Club fungi cultivation medium and production method thereof

A technology of cultivation substrate and production method, applied in mushroom cultivation, cultivation, plant cultivation and other directions, can solve the problems of insufficient quality and low yield of antler mushrooms, reduce pollution rate, improve disease resistance and anti-miscellaneous bacterial infection ability, The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) corn is crushed into sawdust powder;

[0056] 2) pre-wet the corn cob;

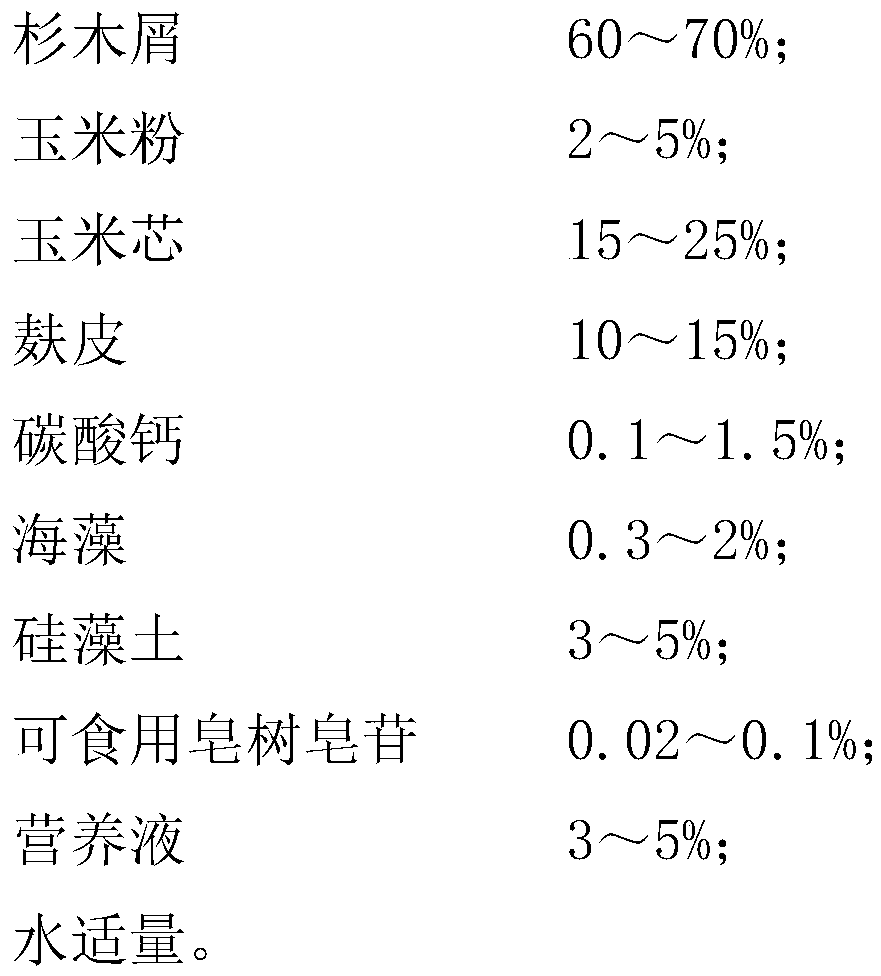

[0057] 3) take by weighing 2% by weight of corn flour, 10% by weight of bran, 0.1% by weight of calcium carbonate, 60% by weight of Chinese fir chips, and 15% by weight of corn cobs, mix thoroughly, then add water, stir well;

[0058] 4) 0.3% by weight of seaweed and 3% by weight of diatomaceous earth are mixed and watered, and then 0.02% of edible Quillaja saponin is put into it and mixed evenly;

[0059] 5) mix the mixture in step 4) with the mixed material in step 3), then sprinkle 3% by weight of the nutrient solution, then continue to stir, and pack the material into bags, each bag of 1kg;

[0060] 6) The bagged material is sterilized by steam at 95°C for 12 hours at normal pressure, and after cooling to normal temperature, the cultivation substrate of pilose antler mushroom is prepared.

[0061] The humidity of the corn cob in the step 2) is 25%.

[0062] The particle size of the Chine...

Embodiment 2

[0066] 1) corn is crushed into sawdust powder;

[0067] 2) pre-wet the corn cob;

[0068] 3) take by weighing the cornflour of 5% weight portion, the bran of 15% weight portion, the calcium carbonate of 1.5% weight portion and the fir sawdust of 70% weight portion, the corncob of 25% weight portion mix, fully stir, then add water, stir well;

[0069] 4) 2% by weight of seaweed and 5% by weight of diatomaceous earth are mixed and watered, and then 0.1% of edible Quillaja saponin is put into it to mix evenly;

[0070]5) mix the mixture in step 4) with the mixed material in step 3), then sprinkle 5% nutrient solution by weight, then continue stirring, and pack the material into bags, each bag of 1.2kg;

[0071] 6) The bagged material is sterilized by steam at 120°C for 18 hours at normal pressure, and after cooling to normal temperature, the cultivation substrate of pilose antler mushroom is prepared.

[0072] The humidity of the corncob in the step 2) is 40%.

[0073] The pa...

Embodiment 3

[0077] 1) corn is crushed into sawdust powder;

[0078] 2) pre-wet the corn cob;

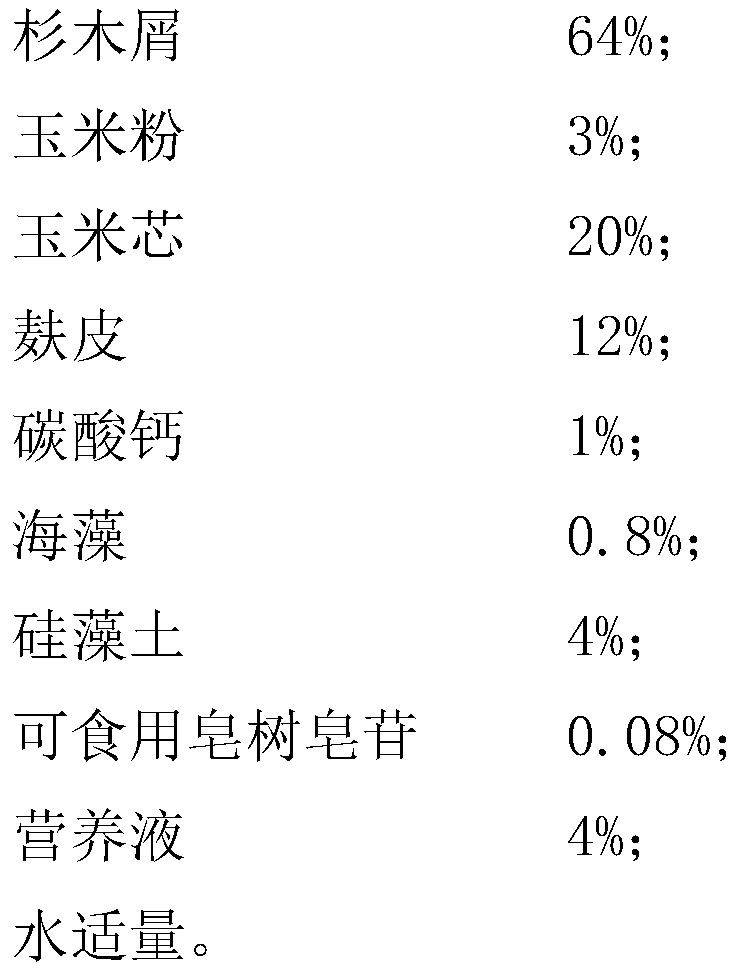

[0079] 3) take by weighing the cornflour of 3% weight portion, the bran of 12% weight portion, the calcium carbonate of 1% weight portion and the Chinese fir sawdust of 64% weight portion, the corncob of 20% weight portion mix, fully stir, then add water, stir well;

[0080] 4) 0.8% by weight of seaweed and 4% by weight of diatomaceous earth are mixed and watered, and then 0.08% of edible Quillaja saponin is put into it and mixed evenly;

[0081] 5) mix the mixture in step 4) with the mixed material in step 3), then sprinkle 4% by weight of the nutrient solution, then continue stirring, and pack the material into bags, each bag of 1kg;

[0082] 6) The bagged material is sterilized by steam at 120°C for 18 hours at normal pressure, and after cooling to normal temperature, the cultivation substrate of pilose antler mushroom is prepared.

[0083] The humidity of the corn cob in the step 2) is 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com