Mask manufacturing process and mask

A production process and mask technology, which is applied in the field of masks, can solve the problems of high total cost of equipment, inconvenient production management, and time-consuming, etc., and achieve the effects of good batch production capacity, improved contact sealing, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

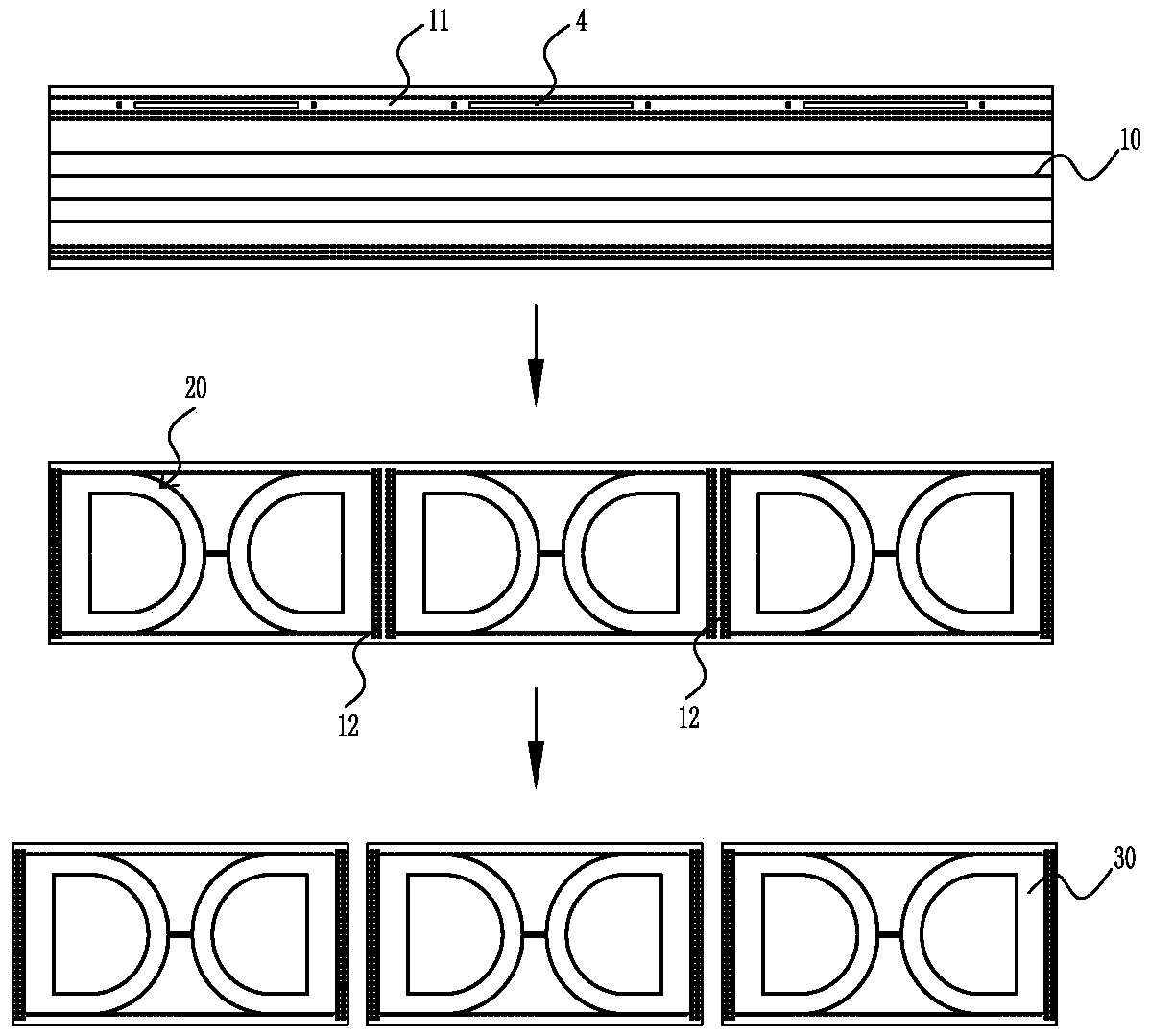

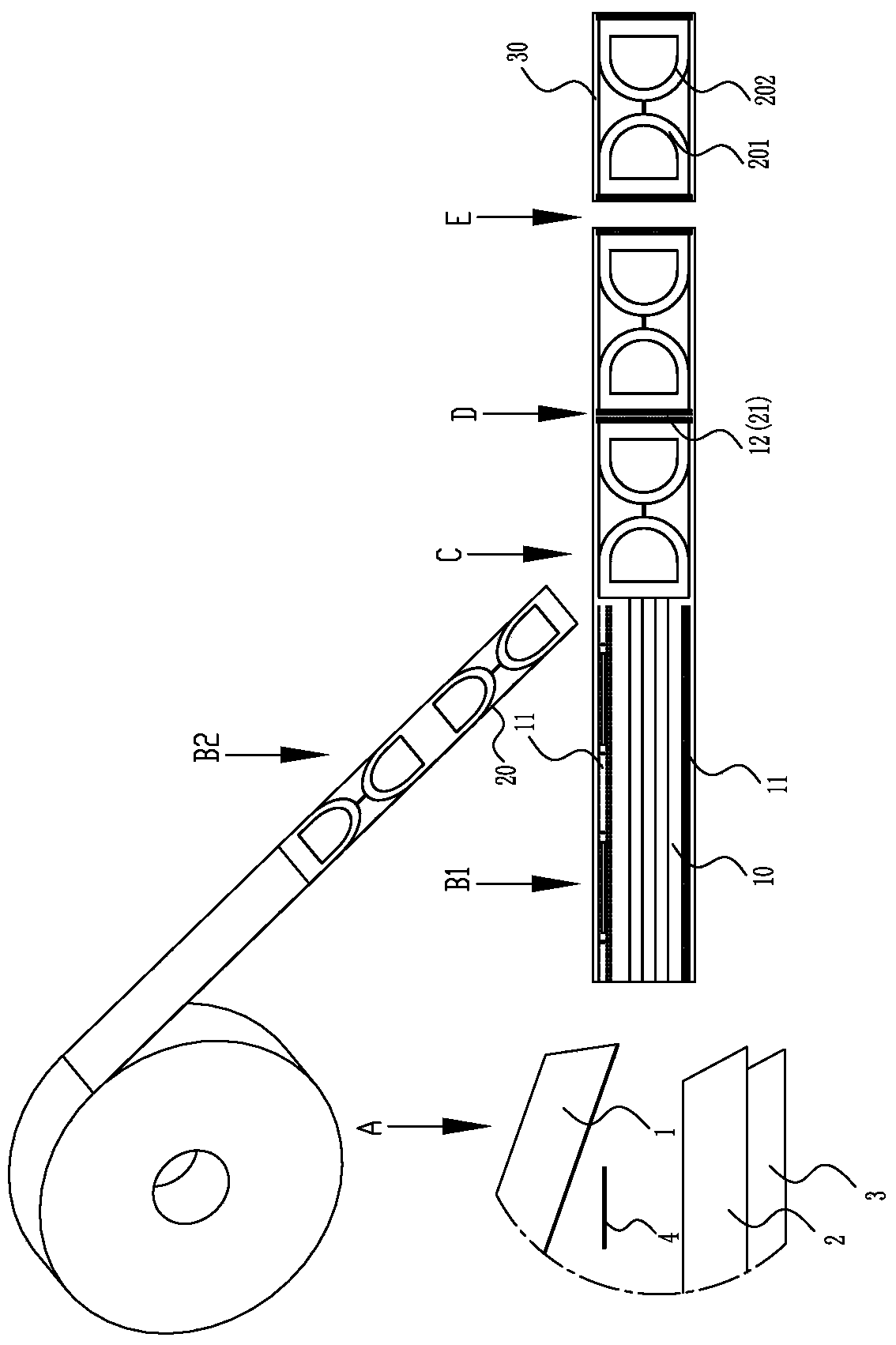

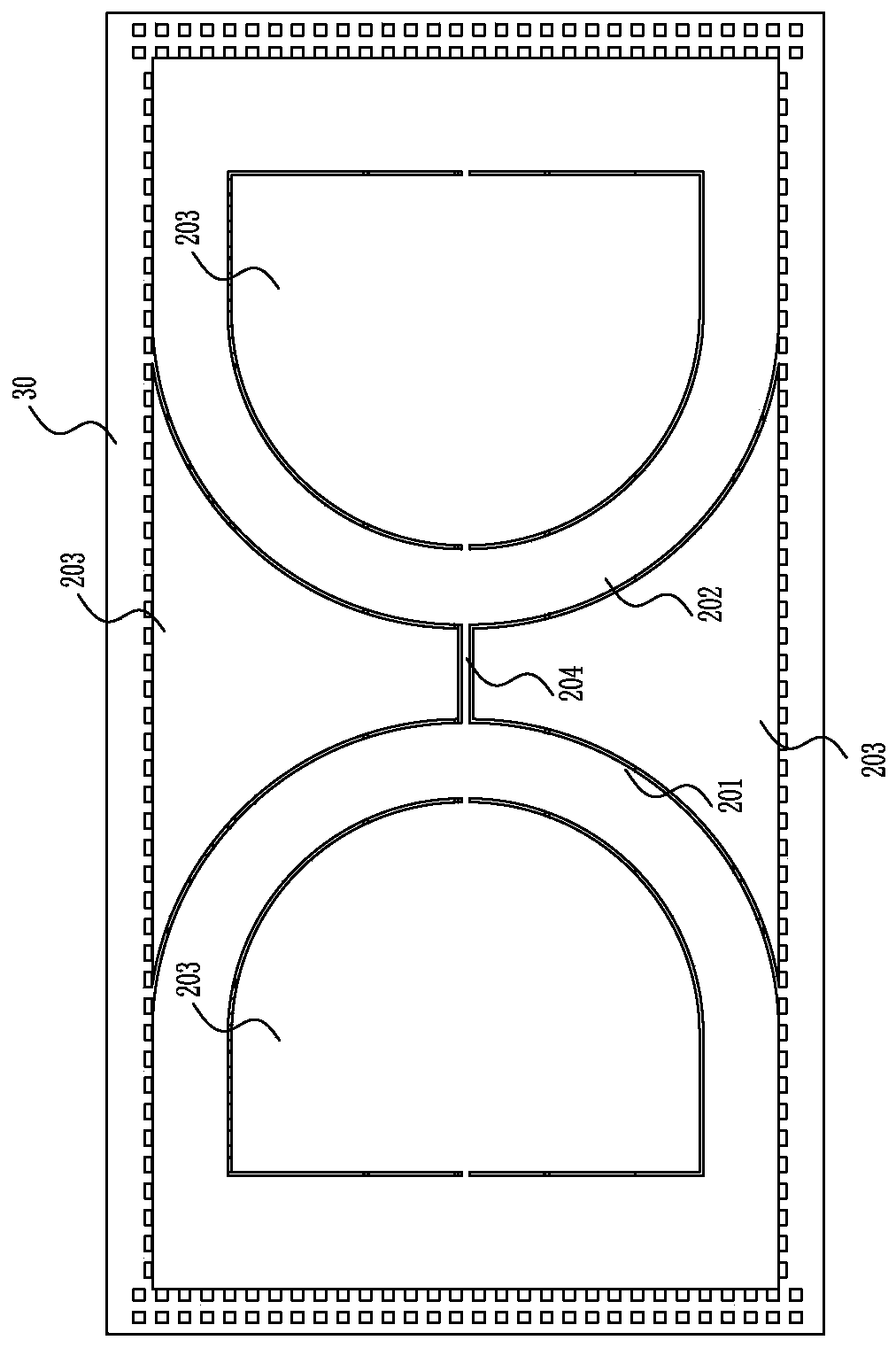

[0037] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure and process of the embodiment of the present invention. In this embodiment, take the plane mask as an example for illustration.

[0038] A mask manufacturing process, at first, prepare mask main sheet and elastic fabric:

[0039] The mask body sheet is arranged along the transverse extension to form several continuous mask body units; the longitudinal ends of the mask body sheet are formed with laterally extending lateral fusing edges to form several continuous mask body units. The main sheet of the mask generally includes three layers: the inner layer is a skin-friendly material, the middle layer is an isolation filter layer, and the outer layer is a waterproof non-woven fabric or a special material antibacterial layer, etc. The common ones are: outer non-woven fabric 1, meltblown Cloth 2, inner non-woven fabric 3. Of course, the specific structure of the mask body sheet of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com