A colloidal foam fire extinguishing agent suitable for high-level fire sources and concealed fire sources in coal mines

A technology of colloidal foam and fire extinguishing agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of no fire extinguishing agent that can effectively control hidden fire sources, poor suppression effect of high-level fire sources, and difficult control of hidden fire sources, so as to prevent spontaneous combustion and increase Intensity, complete fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix the following components in mass percentage to obtain a colloidal foam fire extinguishing agent suitable for high fire sources and concealed fire sources in coal mines:

[0032] Refractory soil (150 mesh particle size) 2%, w-101 composite foaming agent 25%, cooked rubber powder 5%, fly ash (200 mesh particle size) 5%, and the balance is water.

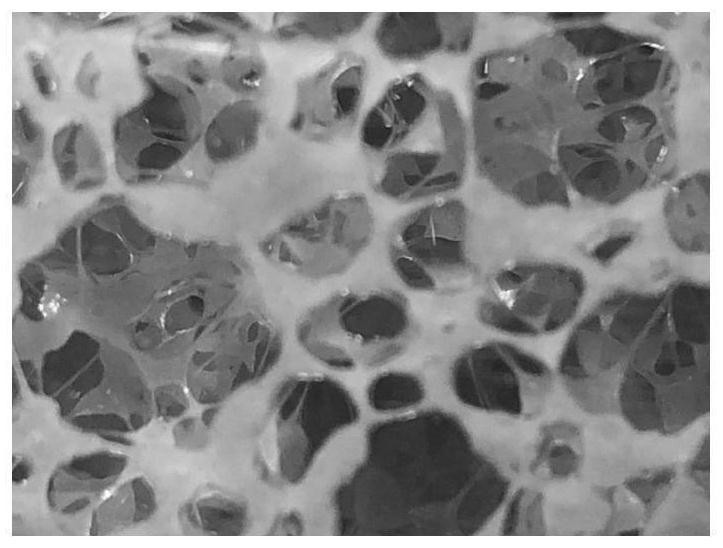

[0033] After the colloidal foam fire extinguishing agent obtained in this embodiment is shaken and foamed in a container, the structure of its internal colloidal crystals is collected, such as figure 1 shown by figure 1 It can be seen that the colloidal foam fire extinguishing agent obtained in this embodiment forms a reticular foam group after foaming.

Embodiment 2

[0035] Mix the following components in mass percentage to obtain a colloidal foam fire extinguishing agent suitable for high fire sources and concealed fire sources in coal mines:

[0036] Refractory soil (150 mesh particle size) 1.5%, w-101 composite foaming agent 27%, cooked rubber powder 3%, fly ash (200 mesh particle size) 7%, and the balance is water.

Embodiment 3

[0038] Mix the following components in mass percentage to obtain a colloidal foam fire extinguishing agent suitable for high fire sources and concealed fire sources in coal mines:

[0039] Refractory soil (150 mesh particle size) 1%, w-101 composite foaming agent 30%, cooked rubber powder 3.5%, fly ash (200 mesh particle size) 9%, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com