Equipment and method for forming isotropic polyurethane composite sleeper in one operation

A composite sleeper, isotropic technology, used in tracks, roads, buildings, etc., can solve the problems of easy cracking, large anisotropy, and complicated production processes, so as to improve the molding effect and solve the problem of excessive anisotropy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

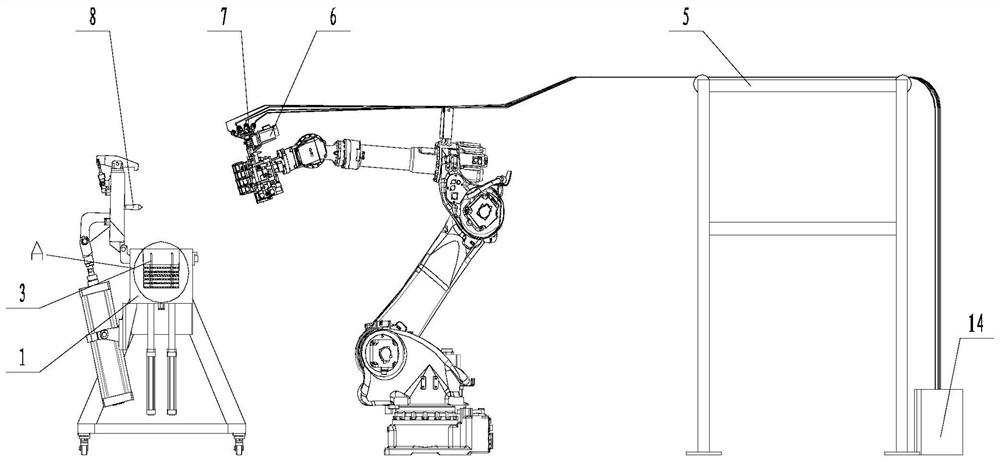

[0036] Such as Figure 1 to Figure 3 The one-time forming isotropic polyurethane composite sleeper molding equipment shown includes a sleeper mold 1, a glass fiber mat positioning mechanism located in the sleeper mold 1, a pouring mechanism for adding short glass fibers to the sleeper mold 1, and a filling mechanism for the sleeper mold. 1 Polyurethane pouring equipment 2 for injecting polyurethane foaming agent.

Embodiment 2

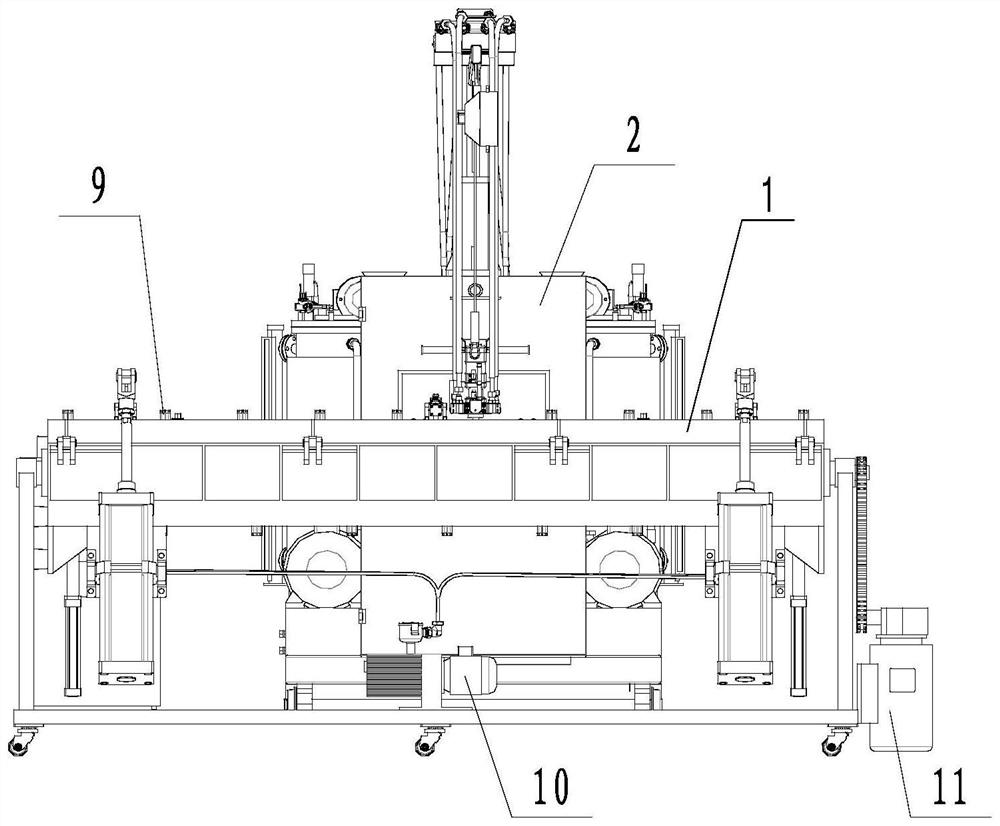

[0038] Such as Figure 1 to Figure 3 In the isotropic isotropic polyurethane composite sleeper molding equipment shown, on the basis of Example 1, the sleeper mold 1 includes an upper mold and a lower mold, and a sleeper spike embedded part 8 is arranged at the bottom of the upper mold. The pouring mechanism includes a glass fiber conveying mechanism 5 for conveying continuous glass fibers, a glass fiber cutting mechanism 6 for cutting continuous glass fibers into short glass fibers, and a dispersion mechanism 7 for cutting short glass fibers into short glass fibers. The glass fibers are dispersed into the sleeper mold 1 . The sleeper mold 1 comprises a patrix and a lower die; an exhaust valve 9 is arranged at the top of the patrix; a vacuum device 10 is also provided, and the vacuum device 10 is detachably connected with the bottom of the lower die, and the vacuum device 10 is used for The air inside the sleeper mold 1 is extracted. It also includes a rocking mechanism 11, ...

Embodiment 3

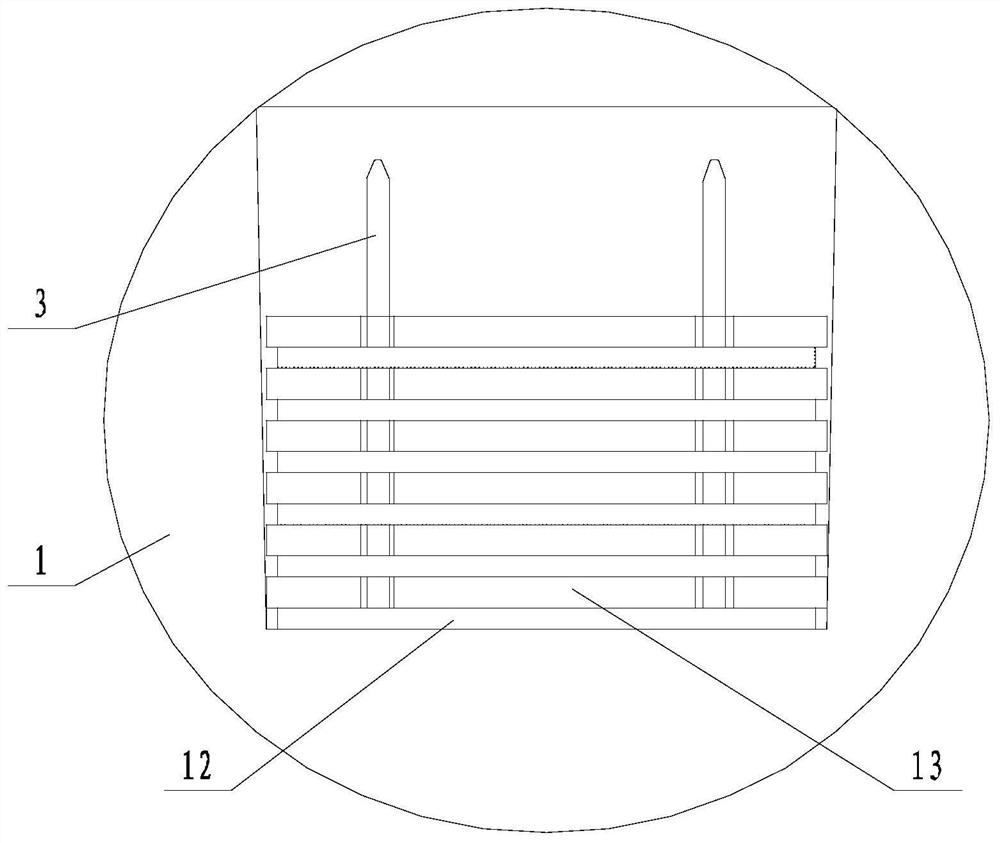

[0041] Such as Figure 1 to Figure 6 In the isotropic isotropic polyurethane composite sleeper molding equipment shown, on the basis of any of the above-mentioned embodiments, the glass fiber felt positioning mechanism includes a tensioning guide device 3 and a clamp 4, and the opposite sides of the glass fiber felt pass through The clamp 4 is clamped, and the clamp 4 is detachably connected to the tension guide device 3 . The sleeper mold 1 includes an upper mold and a lower mold; the tension guide device 3 is a guide column fixed in the lower mold; the clamp 4 is provided with a through hole 401 for the guide column to pass through. A boss 402 is provided at the bottom of the clamp 4 ; between two adjacent clamps 4 up and down, the boss 402 of the upper clamp 4 sits on the lower clamp 4 .

[0042] The specific work process of this embodiment is:

[0043] First, paint the inner wall of the sleeper mold 1 in advance; in the sleeper mold 1, the glass fiber mat 12 and the shor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com