Recycling method of coating water-based colored paint waste solvent

A waste solvent and color paint technology, which is applied in the field of recycling waste solvents for vehicles, can solve problems such as potential safety hazards in painting workshops, reduce hazardous waste treatment costs and raw material costs, excellent cleaning capabilities, and achieve hazardous waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

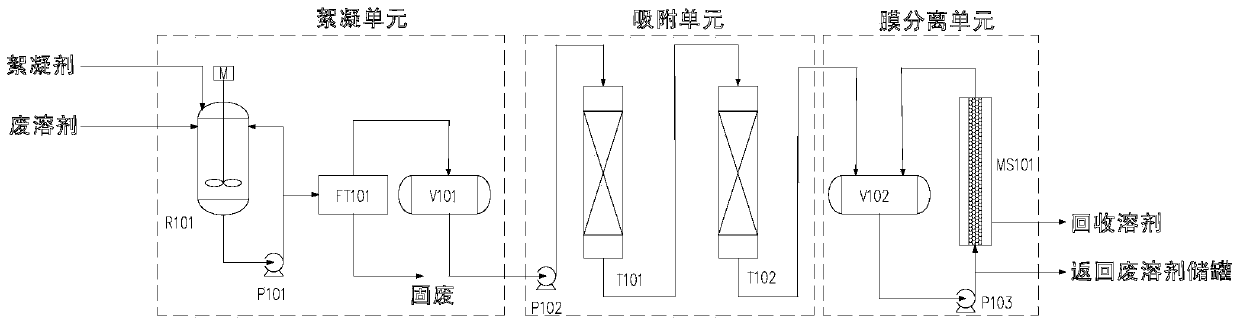

[0028] The settled paint waste solvent is added to the reaction kettle R101, and then the flocculant aqueous solution is added to the reaction kettle R101, wherein the flocculant aqueous solution is a mixed aqueous solution of polysilicic acid and polysilicate iron with a mass concentration of 2%, and the flocculant aqueous solution and the waste solvent The mass ratio of the suspension is 0.1:4, and after being fully stirred, it is transported to the filter FT101 by the suspension delivery pump P101. The filter FT101 filters out the solid impurities after flocculation, and the clear liquid enters the clear liquid tank V101. The clear liquid delivery pump P102 transports the clear liquid to the primary adsorption tower T101 filled with activated carbon and the secondary adsorption tower T102 filled with ion exchange resin in sequence, and then enters the mother liquor tank V102. The mother liquor delivery pump P103 transports the materials in the mother liquor tank V102 to the...

Embodiment 2

[0030] The settled paint waste solvent is added to the reaction kettle R101, and then the flocculant aqueous solution is added to the reaction kettle R101, wherein the flocculant aqueous solution is a mixed aqueous solution of sodium polyacrylate and anionic polyacrylamide with a mass concentration of 0.02%, and the flocculant aqueous solution is mixed with the waste The mass ratio of the solvent is 1.5:4, and after being fully stirred, it is transported to the filter FT101 by the suspension delivery pump P101. The filter FT101 filters out the solid impurities after flocculation, and the clear liquid enters the clear liquid tank V101. The clear liquid delivery pump P102 transports the clear liquid to the primary adsorption tower T101 filled with activated carbon and the secondary adsorption tower T102 filled with ion exchange resin in sequence, and then enters the mother liquor tank V102. The mother liquor delivery pump P103 transports the materials in the mother liquor tank V...

Embodiment 3

[0032] The settled paint waste solvent is added to the reaction kettle R101, and then the flocculant aqueous solution is added to the reaction kettle R101, wherein the flocculant aqueous solution is a cationic polyacrylamide aqueous solution with a mass concentration of 1%, and the mass ratio of the flocculant aqueous solution to the waste solvent is The ratio is 0.5:4. After fully stirring, it is sent to the filter FT101 by the suspension pump P101. The filter FT101 filters out the solid impurities after flocculation, and the clear liquid enters the clear liquid tank V101. The clear liquid delivery pump P102 transports the clear liquid to the primary adsorption tower T101 filled with activated carbon and the secondary adsorption tower T102 filled with ion exchange resin in sequence, and then enters the mother liquor tank V102. The mother liquor delivery pump P103 transports the materials in the mother liquor tank V102 to the membrane separation device MS101. The membrane sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com